Double-pawl intermittent rotating mechanism

A rotating mechanism, double pawl technology, applied in mechanical equipment, belts/chains/gears, transmissions, etc., can solve problems such as affecting service life, low action efficiency, and end wear of pawls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

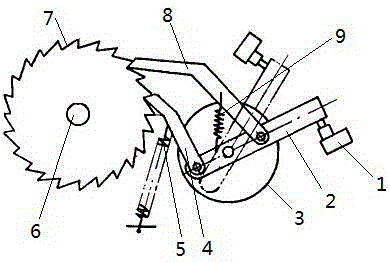

[0012] The reference signs in the accompanying drawings include: limit switch 1, swing rod 2, guide plate 3, first pawl 4, first extension spring 5, ratchet shaft 6, ratchet wheel 7, second pawl 8, second Extension spring 9.

[0013] The embodiment is basically as attached figure 1 As shown: the double-pawl intermittent rotation mechanism of this embodiment includes a swing rod, the middle part of the swing rod is hinged to the support shaft, and the upper end of the swing rod is driven by the piston rod of the cylinder and swings back and forth with the support shaft as a fulcrum. The sides are respectively provided with limit switches that limit the swing range of the swing rod. The ratchet is arranged on the side of the fork, the ratchet is splined on the ratchet shaft, and a brake is arranged on the ratchet shaft.

[0014] The lower end of the swing rod is hinged w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com