Vertical supporting device

A technology of vertical support and mounting rods, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of unable to bear radial force, large size, poor rigidity, etc., achieve good orientation and rigidity, and avoid force Good deformation and support effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

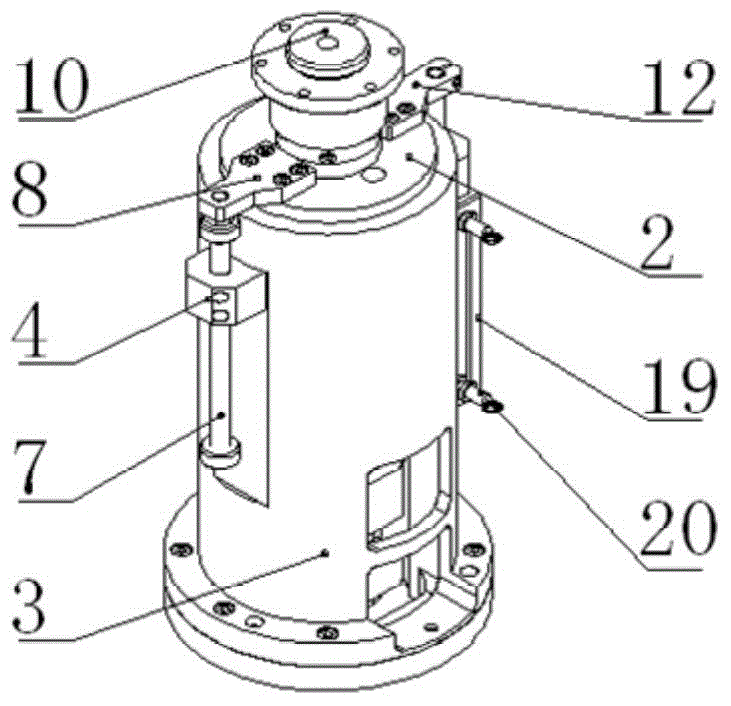

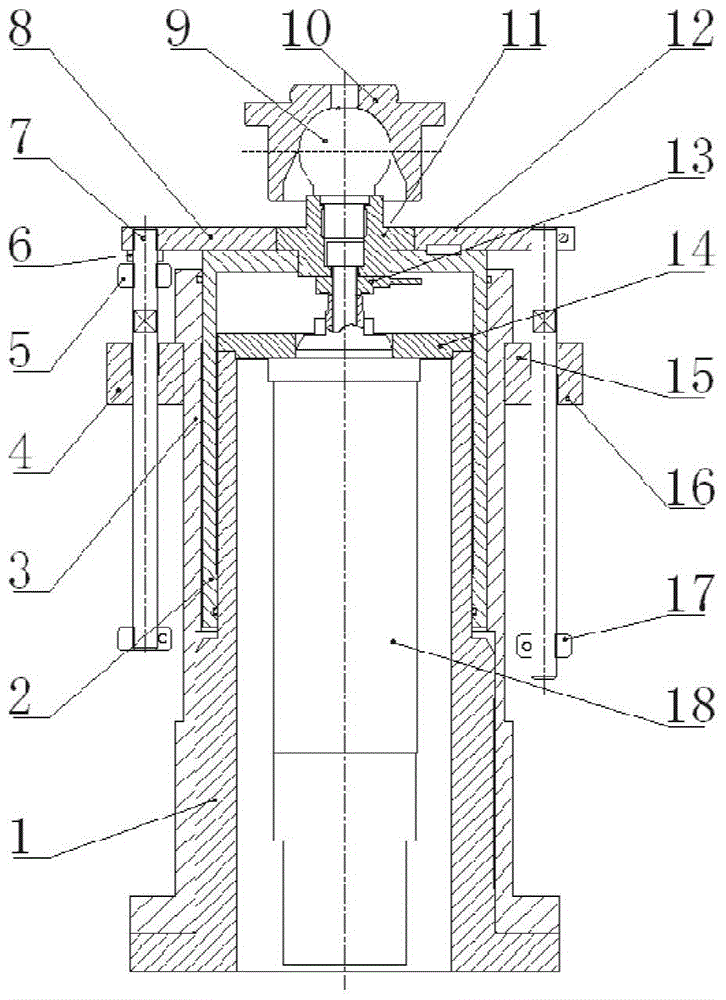

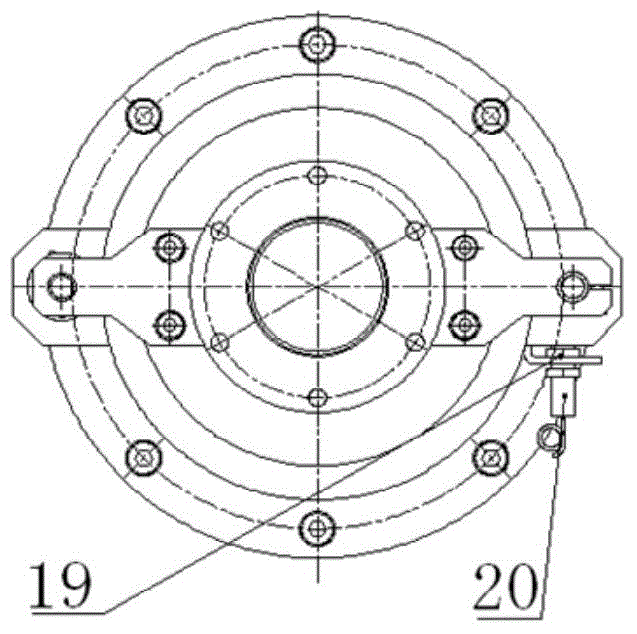

[0019] Such as Figure 1~3 As shown, the vertical support device includes an inner guide seat 1 and an outer guide sleeve 3 placed on its outer layer, and a guide column 2 that can slide along its axial direction is provided between the inner guide seat 1 and the outer guide sleeve 3, The end of the inner guide seat 1 is equipped with a motor mounting seat 14, the servo electric cylinder 18 is placed in the inner guide seat 1 and fixed with the motor mounting seat 14, the connecting seat 11 is installed on the guide column 2, and the servo electric cylinder push rod and The connection base 11 is connected, and a support ball head 9 is installed on the connection base 11, and the support ball head 9 is placed on the ball socket support base 10 to form a ball joint floating support; an anti-rotation connecting plate 12 is fixed on the guide column 2, and the outer guide sleeve An anti-rotation seat 15 is fixed on the side wall of 3, an anti-rotation rod 16 arranged parallel to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com