Discharging mechanism

A technology of blanking and bottom plate, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increasing production cost, low efficiency, and many equipment, and achieve the effect of preventing overtravel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

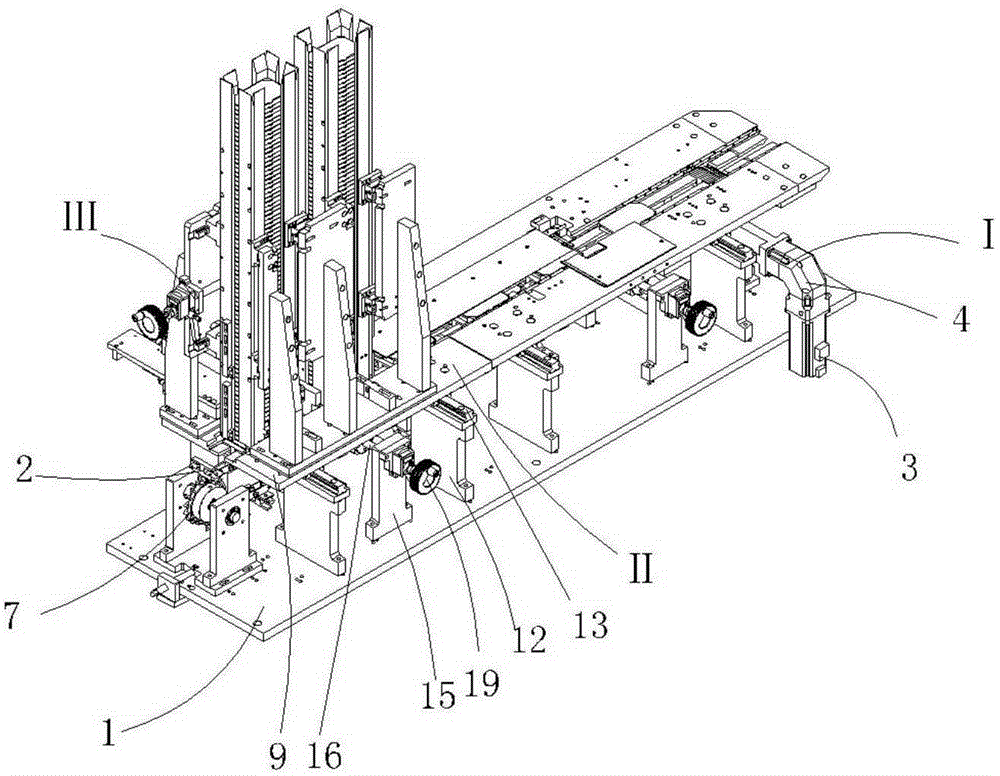

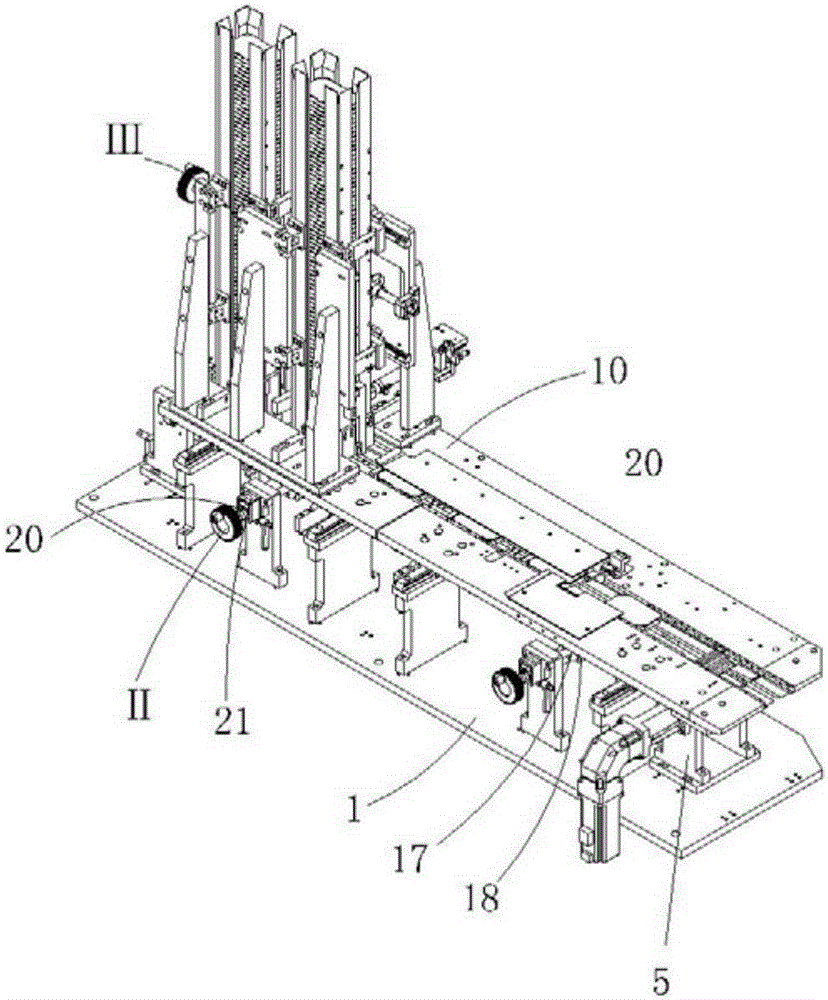

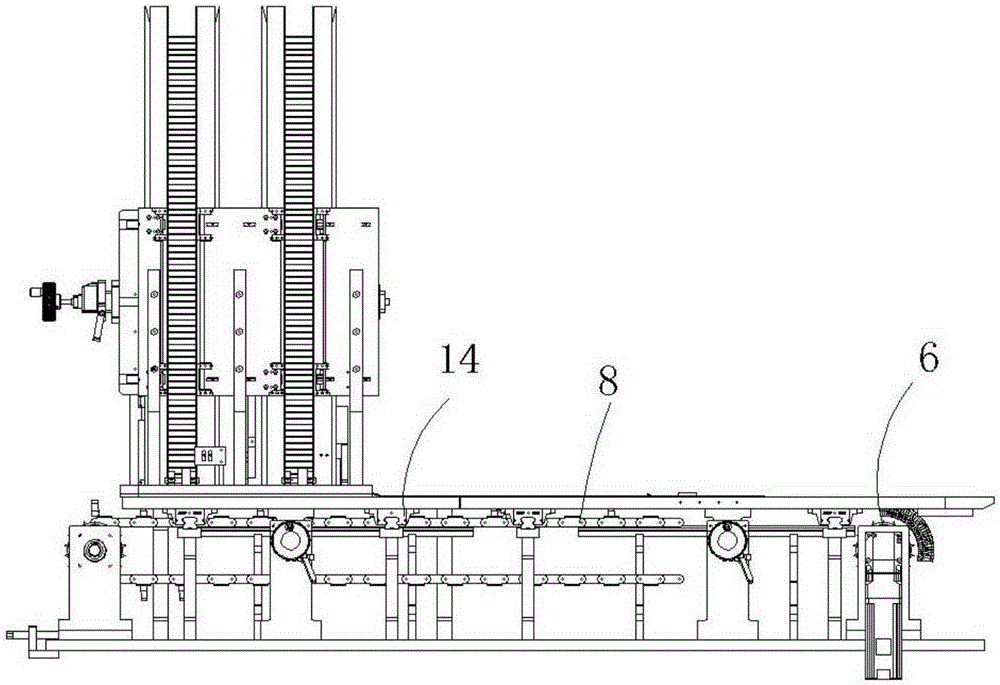

[0032] Examples, see attached Figure 1-13 , which includes a bottom plate 1, on which a transmission assembly I is installed, and multiple groups of shifting blocks 2 are installed on the conveyor belt of the transmission assembly; the transmission assembly includes a motor 3, a reducer 4, a reducer mounting plate 5, a drive Wheel 6, driven wheel 7 and conveyor belt 8, the reducer mounting plate is fixed on the base plate, the reducer is fixed on the reducer mounting plate, the motor is connected to the reducer, the drive wheel is installed on the output shaft of the reducer, and the driven wheel It is installed on the driven shaft, and the driven shaft is supported on the driven shaft seat, and the driving wheel and the driven wheel are connected together through the transmission belt. The motor drives the drive wheel to rotate through the reducer, and the conveyor belt rotates under the action of the driven wheel, thereby driving the shift block to move.

[0033]The front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com