Material bag automatic filling and opening sealing integration facility

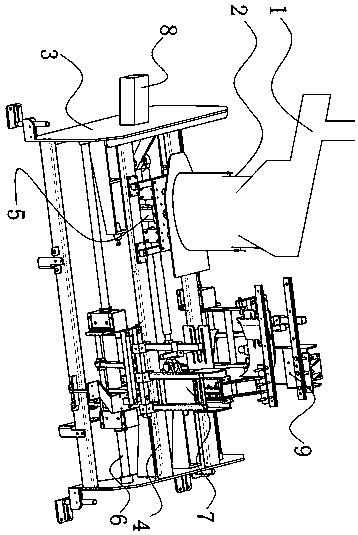

An automatic charging and sealing technology, applied in packaging sealing/fastening, packaging, solid materials, etc., can solve the problems of unrealistic packaging bags, no vibration device, and inability to automatically seal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0033] Embodiment 2, the bag supporting device includes a bag supporting driving motor, an upper gear frame, a lower ring frame, a main pulley, a slave pulley, a rotating belt, a plurality of drawstrings, a plurality of elastic clamping parts and an air blowing part, and the upper gear The top of the frame is installed on the outer wall of the discharge port of the bagging machine 1 through a plurality of vertical support rods one, and the bottom of the upper gear frame is fixed by welding the upper part of the lower ring frame through a plurality of vertical support rods two, and the main pulley and Multiple slave pulleys are installed on the upper part of the upper gear frame at equal intervals, the main pulley and multiple slave pulleys are connected by rotating belts, the fixed end of the bag-supporting drive motor is installed above the upper gear frame through the motor bracket, and the working end of the bag-supporting drive motor It is fixedly connected with the center ...

Embodiment 3

[0036] Embodiment 3, on the basis of Embodiment 2, the elastic clamping part includes a clip, the clip is a plastic clip or a stainless steel clip, one clip leg of the clip is a fixed end, and the other clip leg is a movable end; the clip has an automatic Reset function, that is, the initial state is the closed state. When receiving the pulling force of multiple pull ropes, the distance between the movable end and the fixed end of the clip changes, so that the clip is opened, and the feeding port of the empty woven bag is placed into the opened clip. inside, the clips then close automatically as the tension on the multiple pull cords is removed.

Embodiment 4

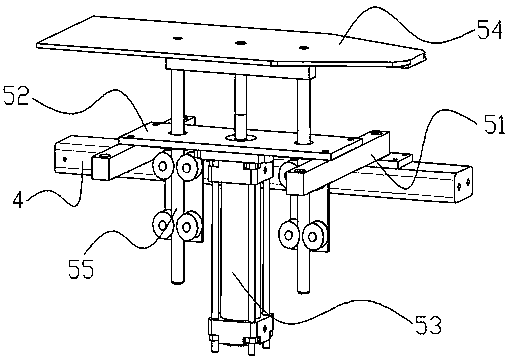

[0037] Embodiment 4, the supporting and vibrating device 5 includes a horizontal support bar 51, a cylinder fixing plate 52, a vibrating lifting cylinder 53, a vibrating bag holder plate 54 and a pair of balance guide assemblies 55, and the pair of horizontal support bars 51 Vertically fixed on the upper part of the middle support member 4, the cylinder fixing plate 52 is fixed between the upper parts of a pair of horizontal support bars 51 by bolts, and the fixed end of the vibrating lifting cylinder 53 is installed at the lower middle position of the cylinder fixing plate 52, and the vibrating lifting The working end of the cylinder 53 runs through the cylinder fixing plate 52 upwards and is fixedly connected with the lower middle position of the vibrating bag holding plate 54. A pair of balance guide assemblies 55 are symmetrically installed on the cylinder fixing plate 52 and positioned at the bottom of the vibration lifting cylinder 53. left and right sides.

[0038] Furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com