Automatic stirring and feeding equipment for pig raising

An automatic stirring and feeding technology, which is applied in the direction of mixer accessories, animal feeding devices, mixers with rotating stirring devices, etc., can solve the problems of heavy labor, high labor intensity, uneven mixing and other problems of the staff, and achieve reduction The effect of labor load, prevention of overtravel, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

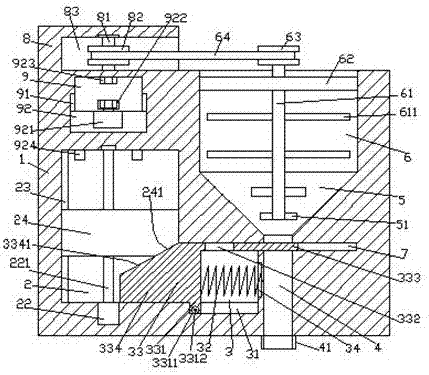

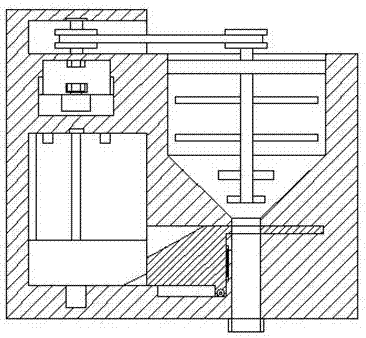

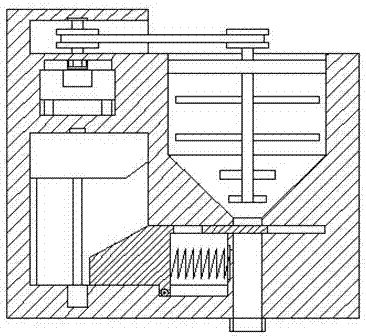

[0023] Such as Figure 1-Figure 5 As shown, a kind of automatic stirring and feeding equipment for raising pigs according to the present invention includes a housing 1, a first sliding chamber 2 is provided inside the left side of the housing 1, and a left inner wall of the first sliding chamber 2 is provided There is a first guide groove 23, and the housing 1 on the right side of the first sliding chamber 2 is provided with a second sliding chamber 3 communicating with the first sliding chamber 2, and the second sliding chamber 3 is on the right side. The housing 1 on the side is provided with a discharge hole 4 extending up and down, and the top of the second sliding chamber 3 is provided with a partition guide groove 7 that runs through the discharge hole 4 transversely and extends to the right. The top of the discharge hole 4 is provided with a funnel-shaped hopper 5, the top of the funnel-shaped hopper 5 is provided with a feed hopper 6, and the housing 1 above the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com