Special-shaped carbon block at side of electrobath

A special-shaped carbon and electrolytic cell technology, applied in the field of cathode carbon blocks, can solve the problems of uneven density of artificial extension legs, shortened life of aluminum electrolytic cells, unfavorable thermal balance of electrolytic cells, etc., so as to prolong life, reduce energy consumption and save maintenance time. Effect

Active Publication Date: 2010-11-24

GUIZHOU BRANCH CHINA ALUMINUM IND

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Domestic large-scale prebaked aluminum electrolytic cells usually use ordinary side carbon blocks and "artificial extension legs", because the "artificial extension legs" of ordinary side carbon blocks are foreign bodies that are attached to the carbon block by artificial binding with carbon paste, and the structure is loose. In the process of firing and starting, as the temperature rises, the defects of uneven density of the "artificial extension legs" are exposed, and the expansion after thermal shock is easy to break, and the artificial "extension legs" form hypertrophic extension legs under low temperature operation, causing current distribution uneven defect

Chinese patent 97212727.5 discloses a special-shaped side carbon block for an aluminum electrolytic cell. The special-shaped side carbon block is a stepped carbon block. The applicant found that the shortcoming of this product is that the carbon block on the upper step is affected by the tank temperature fluctuation during production. , aluminum liquid flow erosion, electrochemical corrosion and other influences, it is easy to damage and leak liquid, which is not conducive to maintaining the thermal balance of the electrolytic cell and shortens the life of the aluminum electrolytic cell

However, after the carbon blocks on the upper steps are damaged, all the special-shaped side carbon blocks can only be replaced, which is a lot of waste. In addition, the electrolytic cell needs to be stopped for overhaul, which increases the production cost.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Login to View More

Abstract

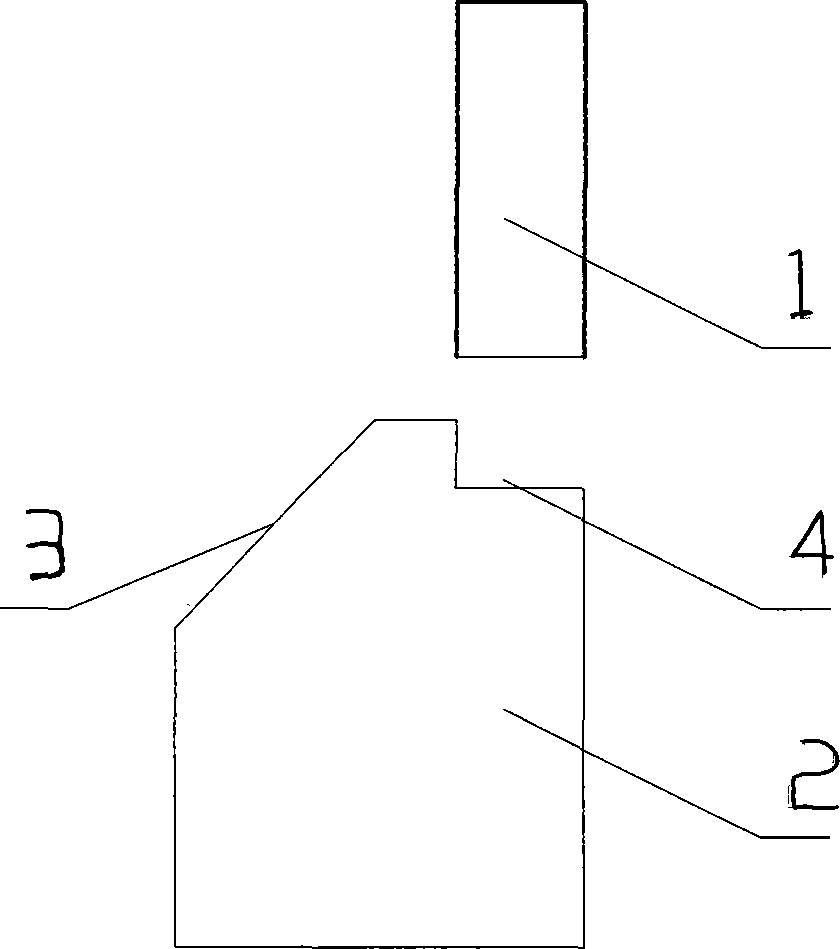

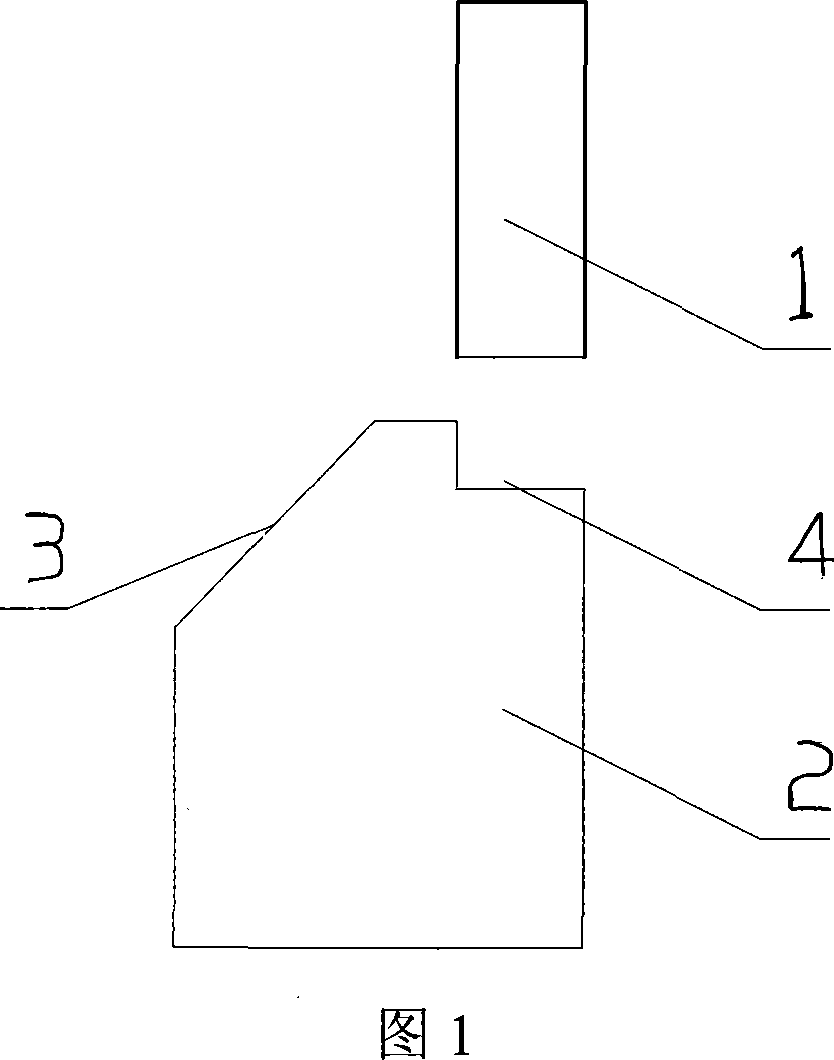

This invention discloses a lateral hetero-shaped carbon block of an electrolytic tank, which comprises an upper carbon block (1) and a lower carbon block (2). The section of the upper carbon block (1) is a rectangle and the side face of the lower carbon block is provided with an extending slope (3). The hetero-shaped carbon block is divided into an upper part and a lower part. The hetero-shaped carbon block is separated; if the upper carbon block is worn during the production process, the upper carbon block can be replaced through minor repair of the electrolytic tank and the lower carbon block can be retained, thereby lowering the production cost and saving the repairing time of the electrolytic tank. A groove is made on the lower carbon block and the upper carbon block is inserted into the groove to reduce the probability of leakage. Compared with the prior art, the hetero-shaped carbon block reduces the energy consumption effectively, further improves the operation stability of thealuminum electrolytic tank and optimizes the technical economic indexes of the aluminum electrolysis technology; the hetero-shaped carbon block also has the advantages of conserving energy, reducing emissions, prolonging the working time of the aluminum electrolytic tank and lowering the production cost.

Description

Special-shaped carbon block on the side of the electrolytic cell technical field The invention relates to a cathode carbon block used at the side of an electrolytic cell, in particular to a special-shaped carbon block at the side of an electrolytic cell. Background technique Domestic large-scale prebaked aluminum electrolytic cells usually use ordinary side carbon blocks and "artificial extension legs". Because the "artificial extension legs" of ordinary side carbon blocks are foreign bodies attached to the carbon block by artificial binding with carbon paste, the structure is loose. In the process of firing and starting, as the temperature rises, the defects of uneven density of the "artificial extension legs" are exposed, and the expansion after thermal shock is easy to be damaged, and the artificial "extension legs" form hypertrophic extension legs under low temperature operation, causing current distribution Uneven defects. Chinese patent 97212727.5 discloses a specia...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25C3/08

Inventor 黎云龚春雷田维红崔健李世军王先黔

Owner GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com