Fluorine water-repellent and oil-repellent agent

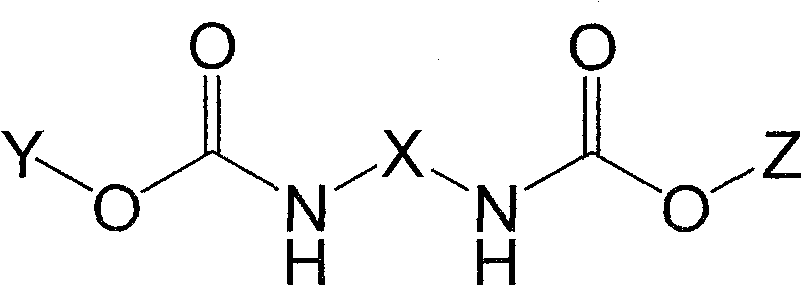

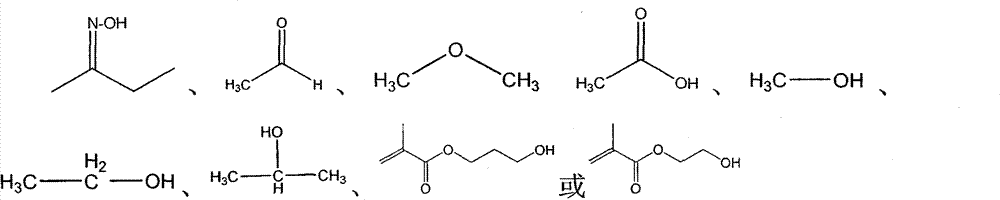

A water-repellent, oil-repellent, fluorine-based technology, applied in the preparation of organic compounds, carbamic acid derivatives, organic chemistry, etc., can solve problems such as monomer residues and acrylic hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

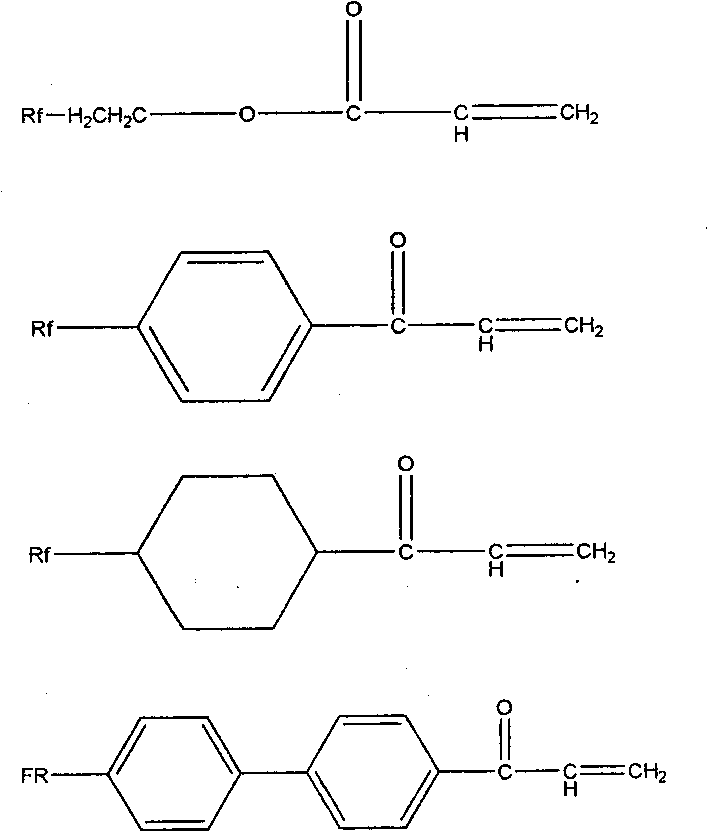

[0109] Synthesis Example 1: Fluorine-containing monomer with urethane structure (D-V1)

[0110] Place 100 grams of IPDI monomer and 0.03 grams of catalyst ES 100Ag catalyst in a three-neck round bottom bottle equipped with a mechanical stirrer, and add 55.6 grams of HEMA (2-hydroxyethyl methacrylate) into the round bottom bottle by dropwise addition, with full temperature control Below 40°C and react for 3 hours. In the second step, add 163 grams of dodecafluoroheptanol (2,2,3,3,4,4,5,5,6,6,7,7-dodecafluorooctan-1-ol) into the circle dropwise In the bottom bottle, the temperature was controlled below 40°C throughout the whole process and the reaction was carried out for 4 hours. After the reaction is completed, 318.6 grams of transparent and colorless mucus can be obtained.

[0111]

Synthetic example 2

[0112] Synthesis Example 2: Fluorine-containing monomer with urethane structure (D-V2)

[0113] Place 100 grams of IPDI monomer and 0.03 grams of catalyst ES 100Ag catalyst in a three-neck round bottom bottle equipped with a mechanical stirrer, and add 55.6 grams of 2-hydroxypropyl methacrylate into the round bottom bottle by dropwise, and the temperature control throughout the process is below 40 °C and reacted for 3 hours. In the second step, 156.6 grams of dodecafluoroheptanol (2,2,3,3,4,4,5,5,6,6,7,7-dodecafluoroheptan-1-ol) was added dropwise into the circle In the bottom bottle, the temperature was controlled below 40°C throughout the whole process and the reaction was carried out for 4 hours. After the reaction is completed, 312.2 grams of transparent and colorless mucus can be obtained.

[0114]

Synthetic example 3

[0115] Synthesis Example 3: Fluorine-containing monomer with urethane structure (D-V3)

[0116] Place 100 grams of IPDI monomer and 0.03 grams of catalyst ES 100Ag catalyst, 149.4 grams of dodecafluoroheptanol (2,2,3,3,4,4,5,5) in a three-necked round bottom bottle equipped with a mechanical stirrer , 6,6,7,7-dodecafluorooctan-1-ol) was added dropwise into the round bottom bottle, the temperature was controlled below 40°C throughout the whole process and reacted for 3 hours. In the second step, 41.2 grams of methyl ethyl ketone oxime (MEKO) was added dropwise into the round bottom bottle, and the temperature was controlled below 40°C throughout the process and reacted for 4 hours. After the reaction is completed, 290.6 grams of transparent and colorless mucus can be obtained.

[0117]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com