Aqueous fluorocarbon coating for painting metal base materials

A water-based fluorocarbon, metal substrate technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

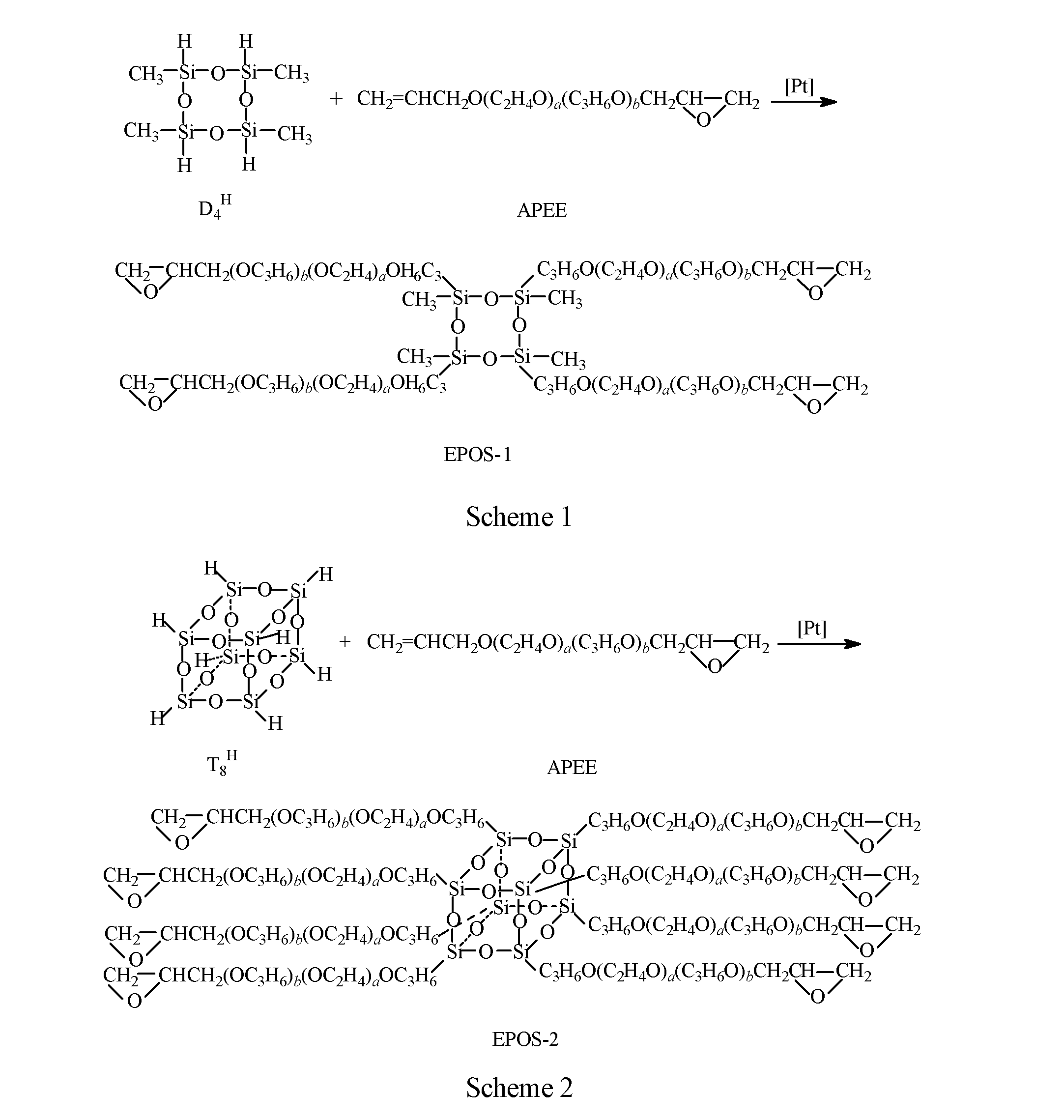

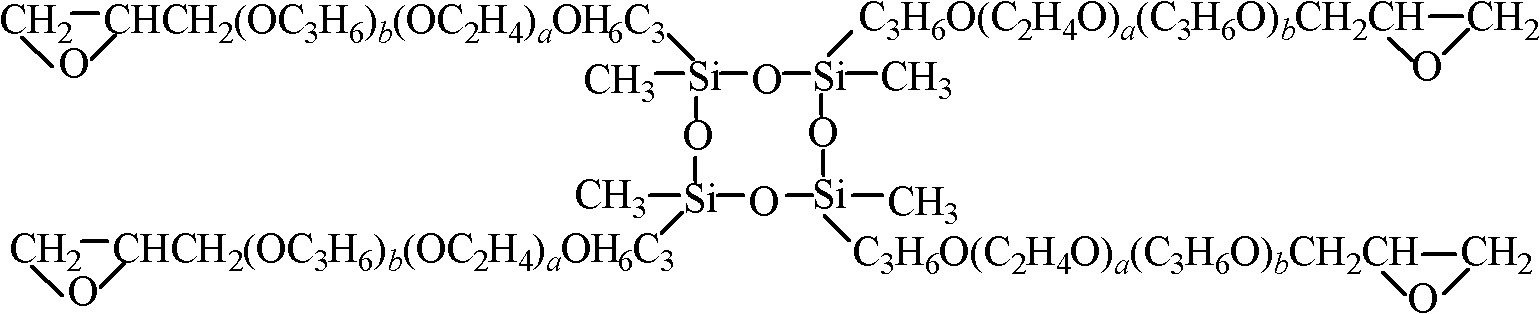

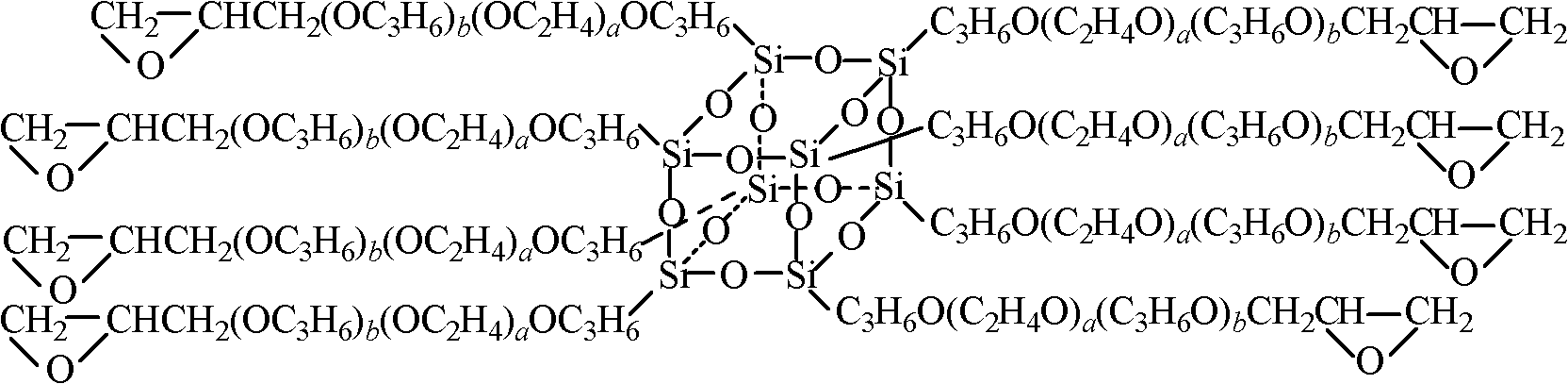

Method used

Image

Examples

Embodiment 1

[0025] (1) Hydrophobic and oleophobic key component of fluorocarbon coatings - preparation of silane / organochlorine co-modified fluororesin emulsion

[0026]Take the preparation of FLCHV resin emulsion as an example. Accurately weigh 27.2g perfluoroalkane ethyl acrylate (FA), 12.8g lauryl methacrylate (LMA), 1.5g hydroxypropyl acrylate (HPA), 2.0g 4-chloromethylstyrene (CMS ), 1.5g vinyltriethoxysilane (VTES), 1.2g sodium perfluoroalkylbenzenesulfonate (FBS), 1.7g fatty alcohol polyoxyethylene ether (AEO-9), 0.4g dodecanethiol, 92.7g of deionized water, mechanically stirred and mixed, and then pre-emulsified by ultrasonic wave at 25±2°C for 20min to make a stable pre-emulsion, recorded as component (I), placed in the dropping funnel (I), and set aside.

[0027] Another 0.8g of potassium persulfate was dissolved in 20g of water to make an aqueous initiator solution, which was recorded as component (II), and placed in the dropping funnel (II) for subsequent use.

[0028] In th...

Embodiment 2

[0043] The key component of hydrophobic and oleophobic fluorocarbon coatings—silane / organochlorine co-modified fluororesin FLCHK emulsion is prepared in Example 1 (1), and the method of crosslinking agent EPOS-1B is described in Example 1 (2).

[0044] In the reactor equipped with a speed-regulating motor, add 100.0g H 2 O, 1.0g dispersant OROTANTM 1124, 1.0g Cathone, stir to make it evenly mixed, then add 1.0g light stabilizer 770 and 100.0g nano-TiO 2 Disperse at high speed for 1 hour, then continue to add 500.0g of acrylic resin BSAHK emulsion, 500.0g of FLCHK emulsion and 30.0g of cross-linking agent EPOS-1B to the system. After stirring and mixing, add 3.0g of hydroxyethylcellulose and 10g of glycerin to adjust The viscosity of the system can be adjusted to obtain a uniform white fluid, that is, water-based fluorocarbon coating.

Embodiment 3

[0046] The key component of hydrophobic and oleophobic fluorocarbon coatings—silane / organochlorine co-modified fluororesin FLCNK emulsion is prepared in Example 1 (1), and the method of crosslinking agent EPOS-1C is described in Example 1 (2).

[0047] In the reactor equipped with a speed-regulating motor, add 200.0g H 2 O, 0.8g sodium polyacrylate PAAS dispersant, 2.0g Cathone, stir and mix well, then add 2.0g light stabilizer-770 and 80.0g nano-iron oxide pigment for high-speed dispersion for 1 hour, and then add 700.0g acrylic resin BSAHK in turn Emulsion, 300.0g FLCNK emulsion and 25.0g cross-linking agent EPOS-1C, after stirring and mixing, add 5.0g hydroxyethyl cellulose and 2.0g leveling agent RM2020 to adjust the viscosity of the system to obtain a uniform white fluid, that is, water-based Fluorocarbon coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com