Water and oil repellent

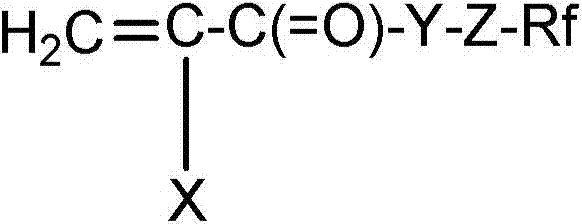

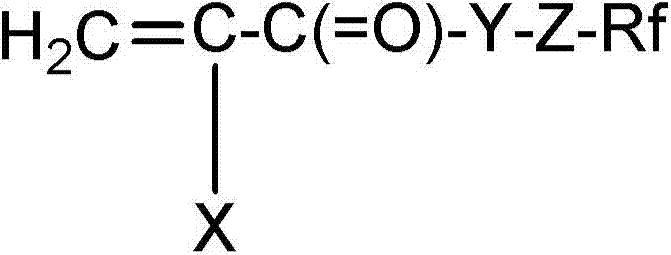

A water-repellent and oil-repellent, monomer technology, used in textiles, papermaking, fiber processing, etc., can solve the problems of poor waterproof and oil-repellent performance of surface treatment agents, adhesion on rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0050] Manufacturing example 1, as shown in Table 3, perfluorooctyl alcohol methacrylate (6FMA) 75g, isobornyl acrylate (IBOA) 15g, glycidyl methacrylate (GMA) 2.5g, diacetone acrylamide (DAAM) 6g, n-dodecyl mercaptan 0.75g, dipropylene glycol methyl ether 43.5g and deionized water 300g were stirred at 50°C for 20 minutes, and homogenized under high pressure at 40MPa. Put the high-pressure homogeneous emulsion into a 1L four-neck glass reaction bottle, add 0.8g of 2,2'-azobisisobutylamidine dihydrochloride, 28g of vinylidene chloride (VDC), and react at 60°C for 6 hours , to obtain an aqueous dispersion of acrylic polymer.

manufacture example 2

[0051] Manufacturing example 2, as shown in Table 3, perfluorooctyl alcohol methacrylate (6FMA) 75g, isobornyl acrylate (IBOA) 24g, glycidyl methacrylate (GMA) 2.5g, diacetone acrylamide (DAAM) 6g, n-dodecyl mercaptan (0.75g), dipropylene glycol methyl ether 43.5g and deionized water 300g were stirred at 50°C for 20 minutes, and homogenized under high pressure at 40MPa. Put the high-pressure homogeneous emulsion into a 1L four-neck glass reaction bottle, add 0.8g of 2,2'-azobisisobutylamidine dihydrochloride, 45g of vinylidene chloride (VDC), and react at 60°C for 6 hours , to obtain an aqueous dispersion of acrylic polymer.

manufacture example 3

[0052] Manufacturing Example 3, as shown in Table 3, perfluorooctyl alcohol methacrylate (6FMA) 100g, isobornyl acrylate (IBOA) 15g, glycidyl methacrylate (GMA) 2.5g, diacetone acrylamide (DAAM) 6g, n-dodecyl mercaptan (0.75g), dipropylene glycol methyl ether 43.5g and deionized water 300g were stirred at 50°C for 20 minutes, and homogenized under high pressure at 40MPa. Put the high-pressure homogeneous emulsion into a 1L four-neck glass reaction bottle, add 0.8g of 2,2'-azobisisobutylamidine dihydrochloride, 45g of vinylidene chloride (VDC), and react at 60°C for 6 hours , to obtain an aqueous dispersion of acrylic polymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com