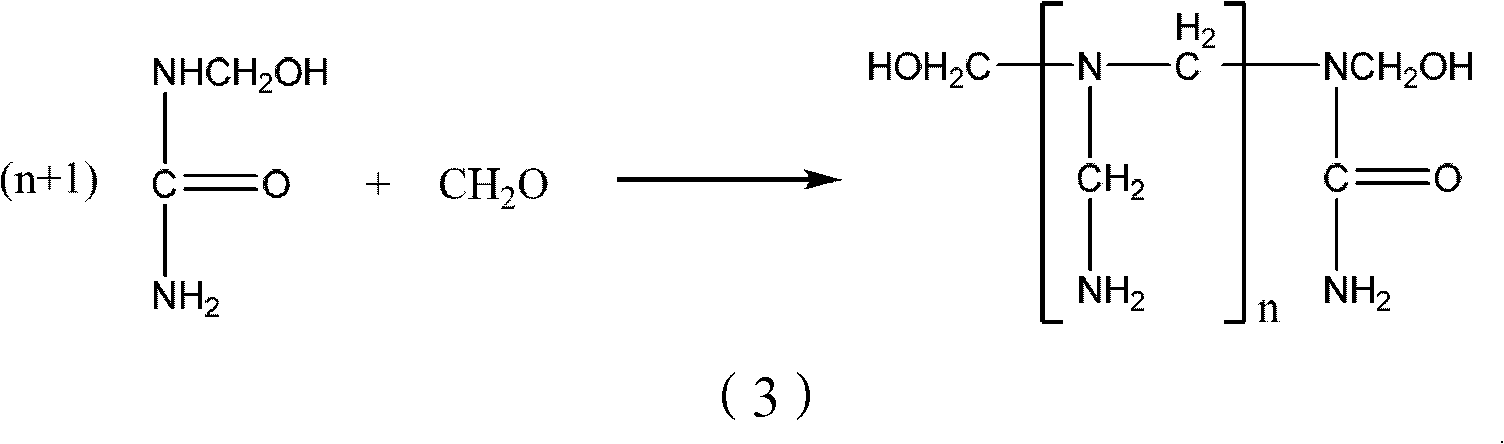

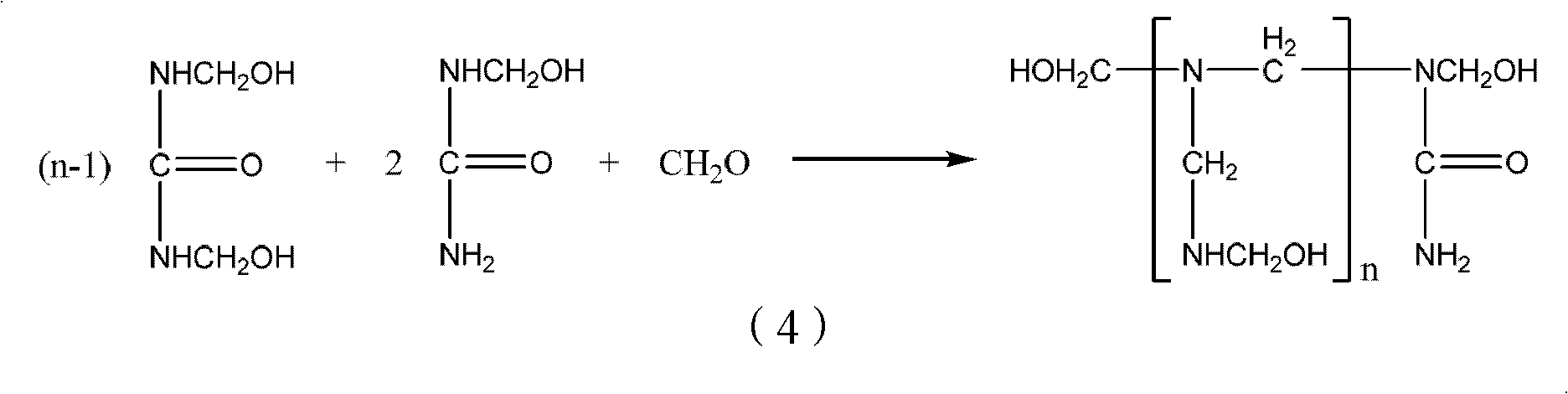

Method for synthesizing urea-formaldehyde resin

A synthesis method and technology of urea-formaldehyde resin, which is applied in the field of synthesis of urea-formaldehyde resin, can solve problems such as difficulty in controlling the end point, prolonging the curing time of the resin, reducing the bonding strength and storage stability of the resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe in detail the technical content, achieved objectives and effects of the present invention, the following will be described in detail in combination with the embodiments.

[0032] Raw materials and reagents:

[0033] Excellent products of melamine;

[0034] Polyvinyl alcohol 2099;

[0035] Urea: industrial grade;

[0036] Formaldehyde: industrial grade (37% aqueous solution by mass percentage);

[0037] Sodium hydroxide, formic acid and ammonium chloride are chemically pure;

[0038] Hydrochloric acid: analytically pure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com