Process for roasting and restoring tailings with weak-intensity magnetism by dragon kiln

A magnetic tailings, roasting technology, applied in the direction of magnetic separation, high gradient magnetic separator, solid separation, etc., can solve the problems of low tailings recovery rate, complex process, high energy consumption, and improve the tailings recovery rate, technology The effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

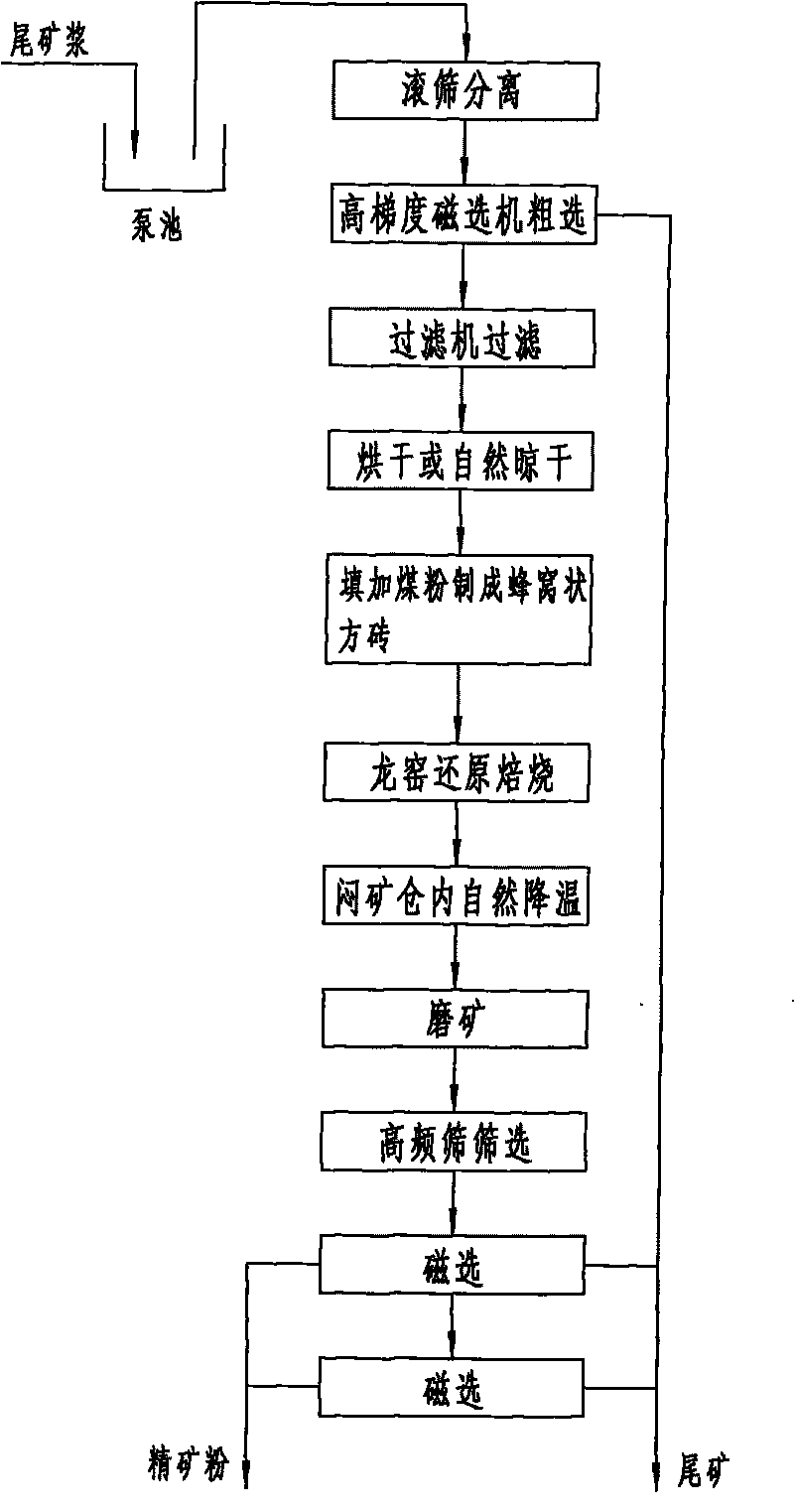

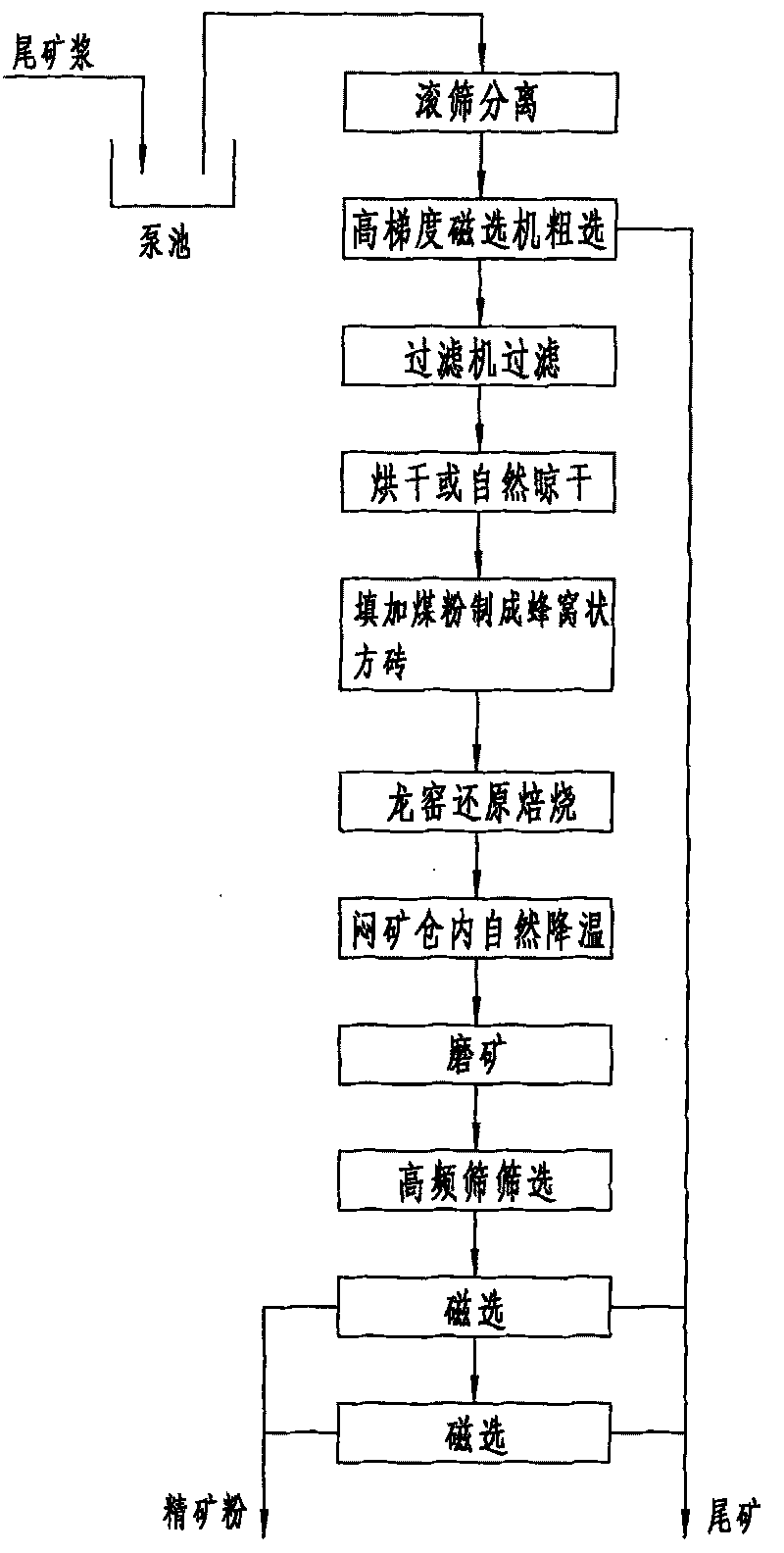

[0019] A kind of dragon kiln roasting reduction weak magnetic tailings process, such as figure 1 As shown, the process steps are as follows:

[0020] a. The tailings slurry is pumped into the roller sieve from the pump pool, and the qualified size minerals are separated by the roller sieve, and sent to the high gradient magnetic separator for rough separation to obtain rougher tailings;

[0021] b. Filter the roughing tailings through a filter so that the water content does not exceed 10% of its total weight, and then dry or dry naturally;

[0022] c. Mix and add pulverized coal in the dried or naturally dried roughing tailings in an appropriate proportion to make honeycomb bricks;

[0023] d. Put the honeycomb square bricks into the kiln chamber of the dragon kiln for reduction roasting. There are boring ore bins under each kiln chamber of the dragon kiln, and a manual movable gate is provided between the kiln chamber and the boring ore bin. After the honeycomb bricks are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com