Ferro-phosphorus aluminum borate whisker preform manufacturing method

A technology of aluminum borate whiskers and a manufacturing method, applied in crystal growth, chemical instruments and methods, self-solids and other directions, can solve problems such as poor performance, complex manufacturing process, poor controllability, etc., and achieve stable and mature technology, simple manufacturing process, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the aluminum borate whisker preform of the present invention comprises the following steps:

[0024] Step 1: Raw material processing. The raw materials used in this method are aluminum hydroxide, boric acid, and iron phosphorus, wherein aluminum hydroxide accounts for 69% to 90% of the total weight, boric acid accounts for 7% to 28% of the total weight, and iron phosphorus accounts for 0.5% to 3% of the total weight. %, the three were ground to 200-500 mesh respectively, then mixed evenly with a mixer, put into a crucible and calcined at 500-1000°C for 3 hours to remove the moisture in the material, and then ball milled through a 200-mesh sieve.

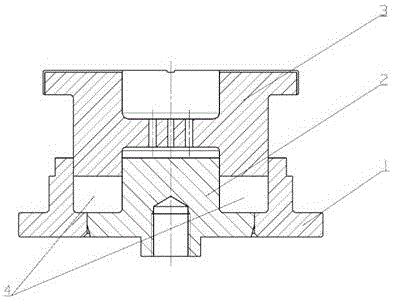

[0025] Step 2: Press molding of the prefabricated body blank. According to the required whisker preform size, shape, volume fraction, etc., determine the process parameters such as material weight and pressing pressure, and put the processed material into the mold, see figure 1 , using a four-column...

Embodiment 1

[0029] The preparation method of the aluminum borate whisker preform (taking the MC07 preform as an example) of the present invention comprises the following steps:

[0030] Step 1: Grind aluminum hydroxide accounting for 85% of the total weight, boric acid accounting for 13% of the total weight, and ferrophosphorus accounting for 2% of the total weight to 200-500 mesh respectively, put them into a mixer, and use 1300 rpm After mixing for 10 minutes, put it into a silicon carbide crucible, calcine in a calcination furnace at a constant temperature of 550°C for 3 hours, and then ball mill it through a 200-mesh sieve.

[0031] Step 2: Connect the mold to the press with bolts, set the pressure of the press to 8MPa, and adjust the upper and lower cylinder stoppers to a suitable position. After the mixed raw materials are calcined, the sieved powder is weighed and put into the mold cavity 4. The volume of the finished MC07 preform is 150 cubic centimeters, the volume fraction is 18...

Embodiment 2

[0035] The preparation method of the aluminum borate whisker preform of the present invention comprises the following steps:

[0036] Step 1: Raw material processing. The raw material used in this method is aluminum hydroxide, boric acid, ferrophosphorus, wherein aluminum hydroxide accounts for 69% of the total weight, boric acid accounts for 28% of the total weight, and ferrophosphorus accounts for 3% of the total weight, and the three are respectively ground to 200- 500 mesh, and then use a mixer to mix evenly, put it into a crucible and calcinate at a temperature of 1000°C for 3 hours to remove the moisture in the material, and then ball mill it through a 200 mesh sieve.

[0037] Step 2: Press molding of the prefabricated body blank. According to the required whisker preform size, shape, volume fraction, etc., determine the process parameters such as material weight and pressing pressure, and put the processed material into the mold, see figure 1 , using a four-column pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com