Method for manufacturing tunable chirped fiber grating

A chirped fiber grating and a manufacturing method are applied in the directions of cladding optical fibers, optical waveguides and light guides, etc., and can solve the problems of application occasions that are difficult to meet fast tuning, difficult manufacturing processes, expensive manufacturing equipment, etc. Stable, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

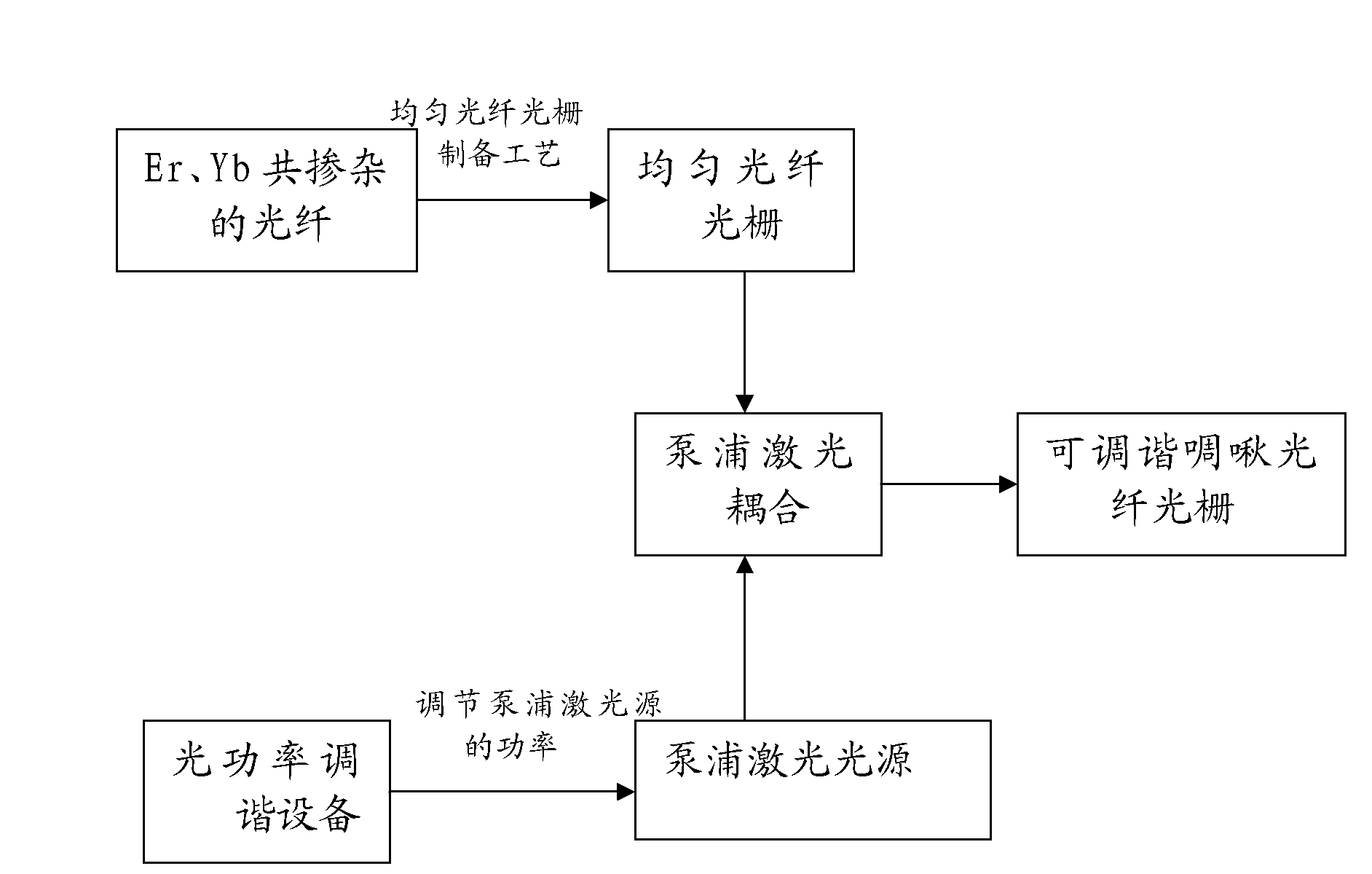

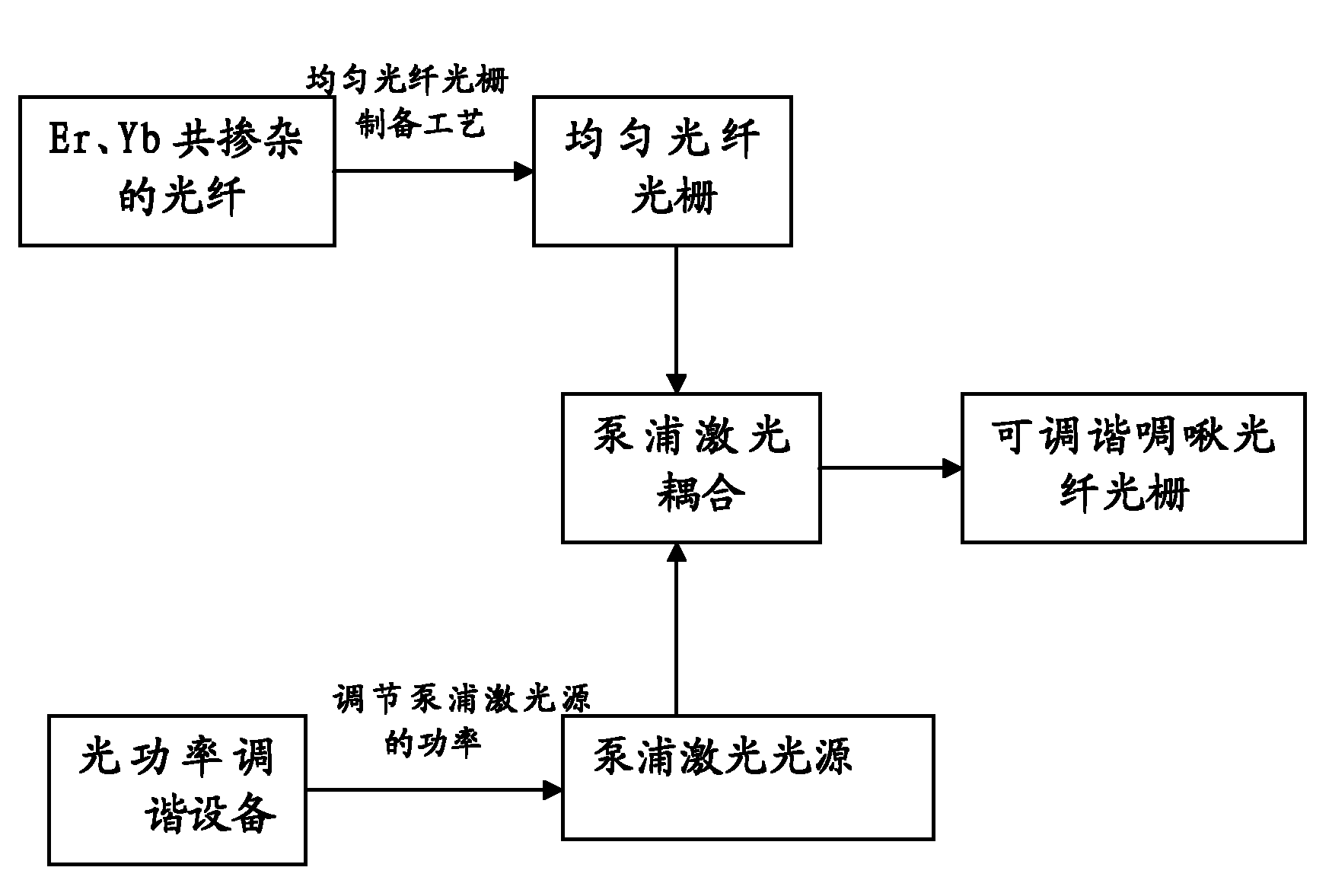

[0027] Such as figure 1 As shown, the fabrication method of the tunable chirped fiber grating of the present invention comprises the following steps:

[0028] (1) Use Er, Yb co-doped fiber to make uniform fiber grating, the specific process is as follows:

[0029] Use a 193nm ultraviolet laser to irradiate the mask to write the optical fiber to obtain a uniform fiber grating. During the process of writing the optical fiber, use a broadband light source and a spectrometer to monitor the writing effect of the fiber grating in real time, and use an optical isolator in the 1550nm band to protect the spectrometer.

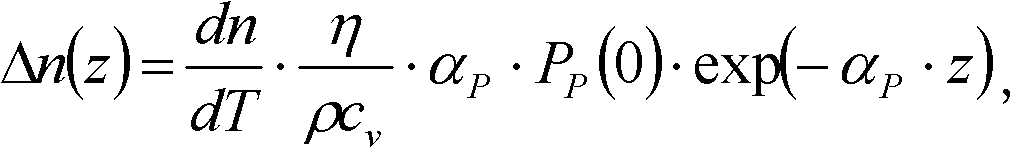

[0030] (2) The pumping laser of 980nm band is coupled into the fiber grating made in step (1) through a wavelength division multiplexing device; the pumping laser produces a temperature gradient that gradually decreases along the laser propagation direction in the fiber grating; The refractive index of the fiber grating forms a refractive index gradient in the fiber gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com