Doublet crystallization polypropylene composite material and preparation method thereof

A technology of crystalline polypropylene and composite materials, applied in coatings and other directions, can solve problems such as limited performance improvement range, and achieve the effects of easy popularization and application, high modulus, excellent impact toughness and heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

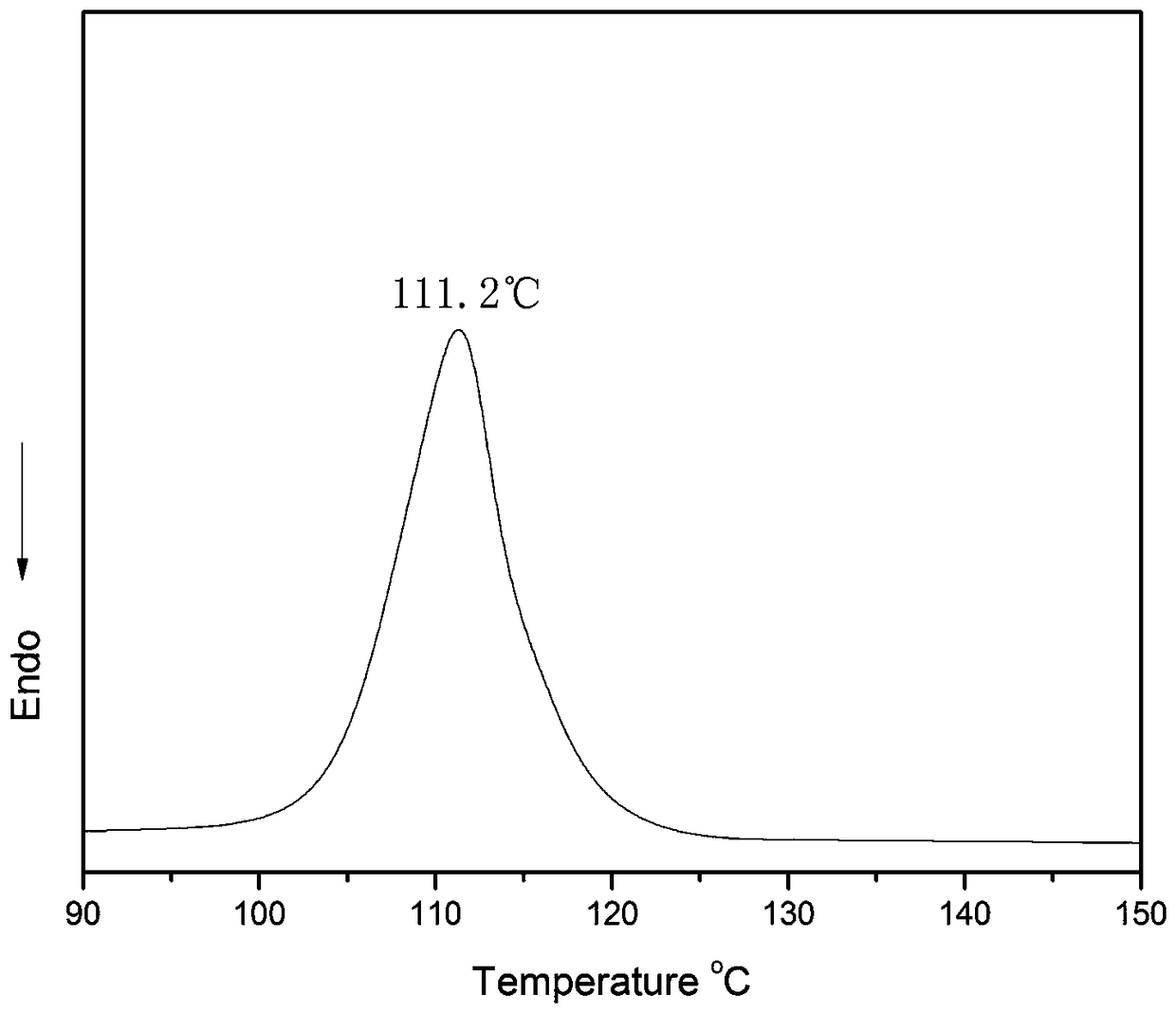

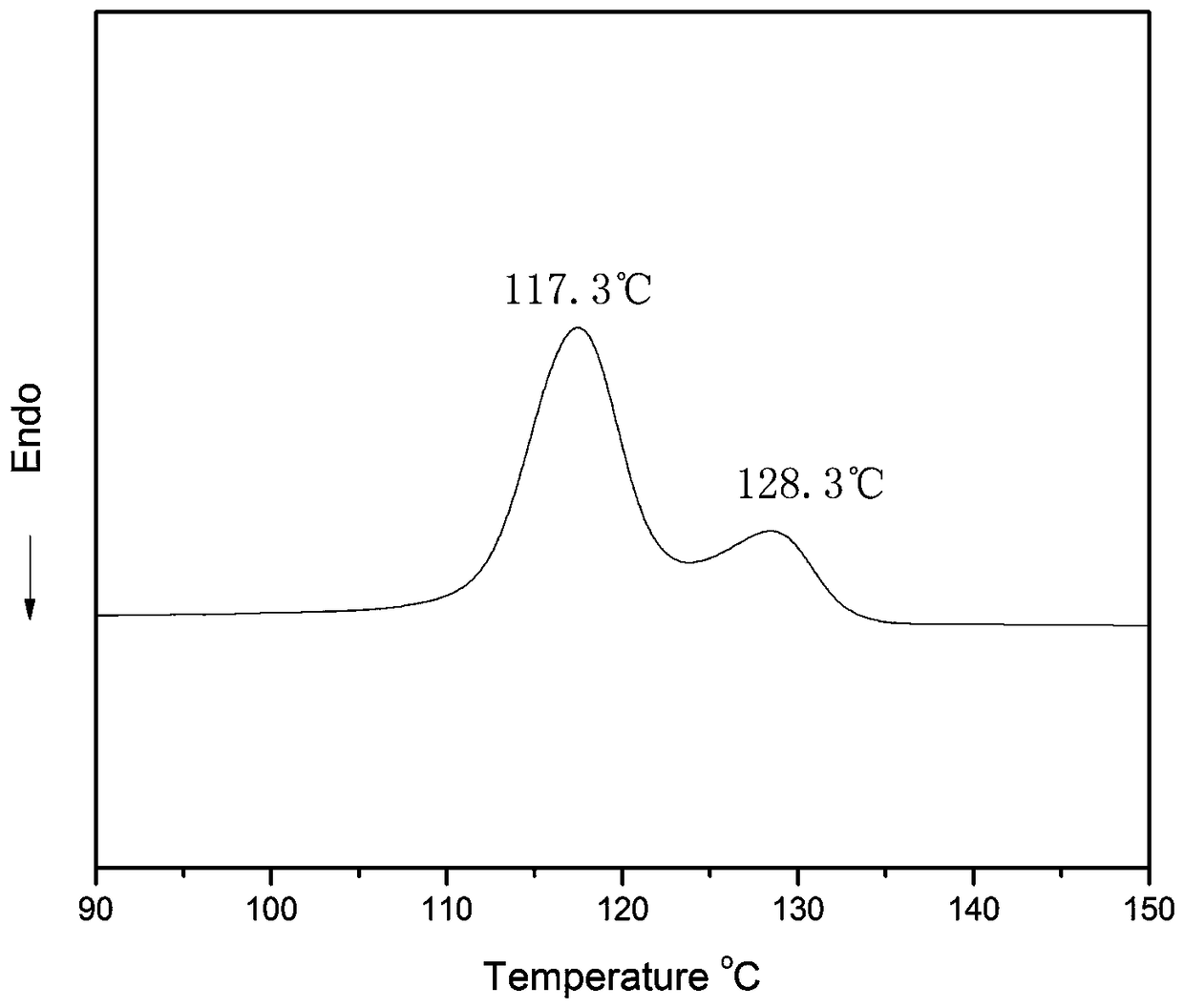

Embodiment 1

[0032] The nucleating agent NA-11 in Comparative Example 2 was replaced by 2,2'-methylene-bis(6-tert-butylphenoxy)lithium phosphate, and the polypropylene composite was prepared under the same conditions. The modified polypropylene material was subjected to differential scanning calorimetry (DSC), nitrogen atmosphere, and a cooling rate of 10°C / min. It was measured that the crystallization peak was a double crystallization peak, and the low temperature peak temperature was 117.3°C, and the high temperature crystallization peak 128.3°C, tensile strength 36.7MPa, flexural modulus 1780MPa, notched impact strength 5.2KJ / m 2 , heat distortion temperature 123.3 ℃, 1mm thick transparent plate fog are 15.6%.

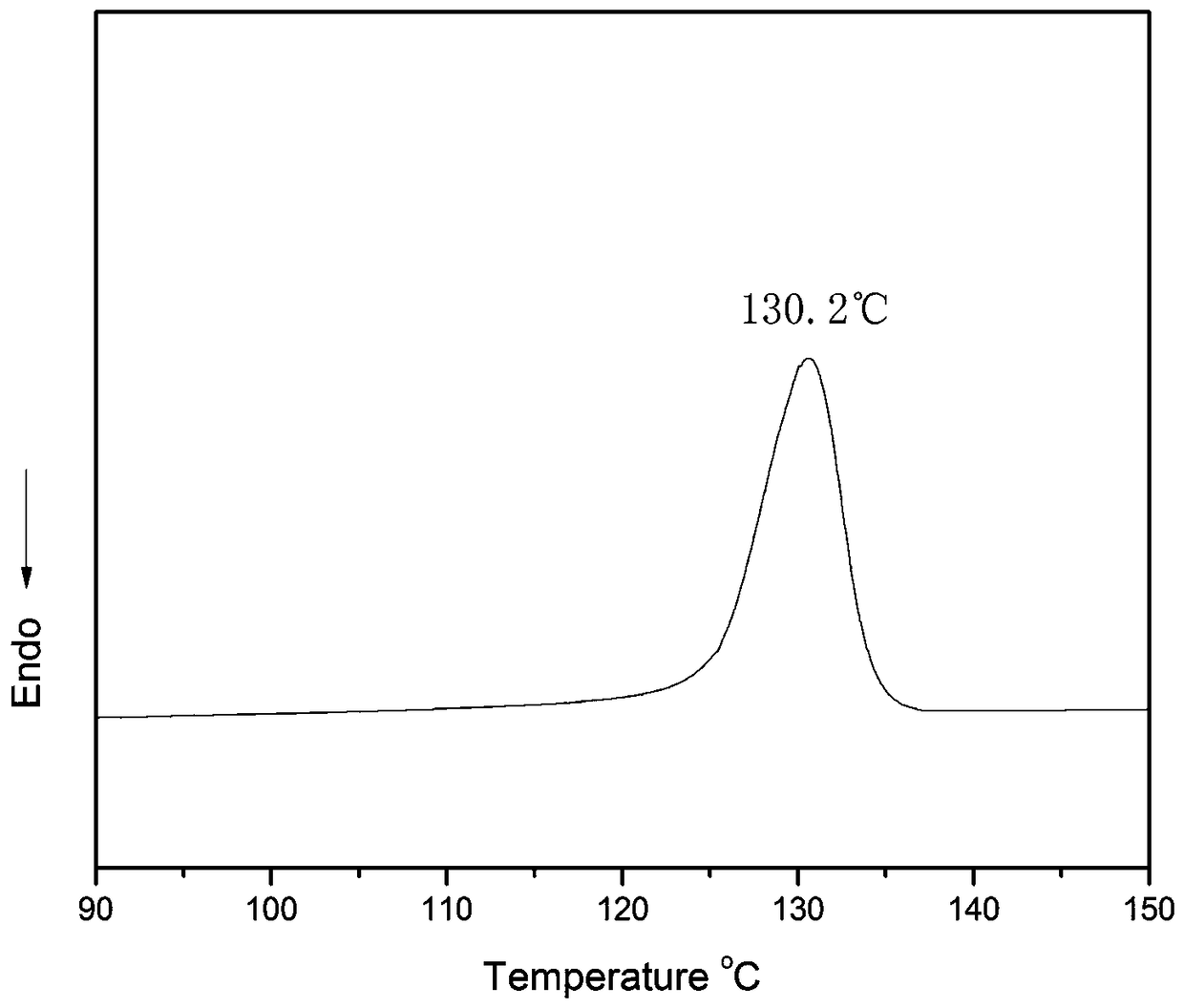

Embodiment 2

[0034] The nucleating agent NA-11 in Comparative Example 2 was replaced with 2,2'-methylene-bis(6-tert-butylphenoxy)phosphate sodium salt, and other conditions were unchanged to prepare polypropylene composite materials. The modified polypropylene material was subjected to differential scanning calorimetry (DSC), nitrogen atmosphere, and a cooling rate of 10°C / min. It was measured that the crystallization peak was a double crystallization peak, the low temperature peak temperature was 118.4°C, and the high temperature crystallization peak 129.2°C, tensile strength 39.3MPa, flexural modulus 2080MPa, notched impact strength 5.2KJ / m 2 , heat distortion temperature 127.6 ℃, 1mm thick transparent plate fog are 14.3%.

Embodiment 3

[0036] The nucleating agent NA-11 in Comparative Example 2 was replaced with 2,2'-methylene-bis(6-tert-butylphenoxy)phosphate potassium salt, and other conditions remained unchanged to prepare polypropylene composite materials. The modified polypropylene material was subjected to differential scanning calorimetry (DSC), nitrogen atmosphere, and a cooling rate of 10°C / min. It was measured that the crystallization peak was a double crystallization peak, the low temperature peak temperature was 117.8°C, and the high temperature crystallization peak was 117.8°C. 127.1°C, tensile strength 37.4MPa, flexural modulus 1920MPa, notched impact strength 5.0KJ / m 2 , heat distortion temperature 125.3 ℃, 1mm thick transparent plate fog are 15.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com