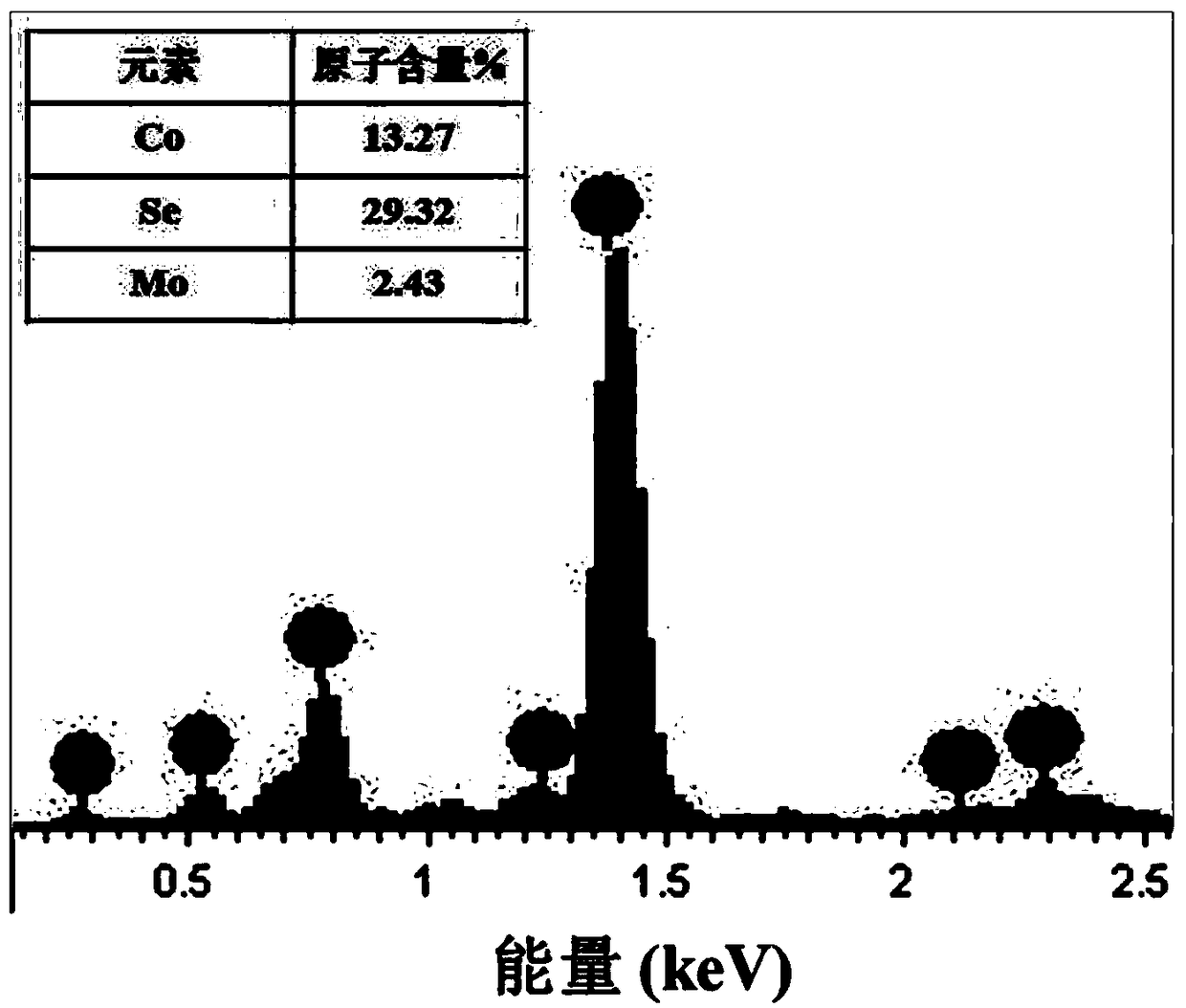

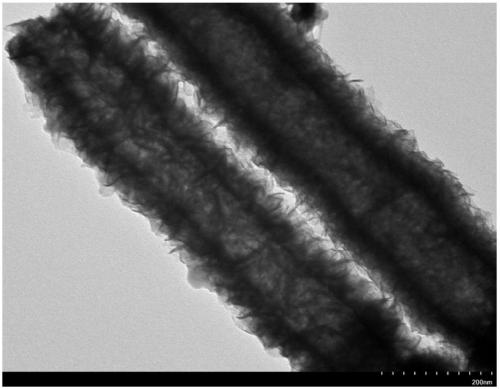

Hollow tubular cobalt-selenium compound/molybdenum-selenium compound composite nano-material and preparation method and application thereof

A technology of composite nanomaterials and selenium compounds, which is applied in the field of inorganic micro-nano material preparation, can solve the problems of poor conductivity, insufficient lamellar catalytic active sites, limited catalytic performance, etc., and achieves controllable reaction, excellent electrochemical performance, process Mature and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A hollow tubular CoSe 2 / MoSe 2 A method for preparing a composite nanomaterial, comprising the steps of:

[0038] A. Weigh 1.5mmol cobalt chloride hexahydrate and 3mmol urea, add 30ml deionized water and stir until dissolved to obtain a clear and transparent solution; transfer the solution to a reaction kettle lined with tetrafluoroethylene, close the reaction kettle and put In a constant temperature box, heat at 90°C for 12h;

[0039] B. After the reaction, the cooled liquid in the reaction kettle was centrifuged to separate the solid product, and after the solid product was cleaned several times, it was placed in a vacuum drying oven and dried at 60°C for 6 hours;

[0040] C, weigh 0.12g of the product obtained in step B, add 30mL N, N-dimethylformamide, stir to make it uniformly dispersed; then add 0.45mmol sodium molybdate (Na 2 MoO 4 ), stirred until completely dissolved;

[0041] D. Add 2mmol of selenium powder into 2mL of hydrazine hydrate, stir until disso...

Embodiment 2

[0047] A hollow tubular CoSe 2 / MoSe 2 A method for preparing a composite nanomaterial, comprising the steps of:

[0048] A. Weigh 2mmol cobalt chloride hexahydrate and 2mmol urea, add 30ml deionized water and stir until dissolved to obtain a clear and transparent solution; transfer the solution to a reaction kettle lined with tetrafluoroethylene, close the reaction kettle and put it into a constant temperature In the oven, heat at 120°C for 10h;

[0049] B. After the reaction, the cooled liquid in the reaction kettle was centrifuged to separate the solid product, and after the solid product was cleaned several times, it was placed in a vacuum drying oven and dried at 60°C for 6 hours;

[0050] C, weigh 0.3g of the product obtained in step B, add 50mL N, N-dimethylformamide, stir to make it uniformly dispersed; then add 0.8mmol sodium molybdate (Na 2 MoO 4 ), stirred until completely dissolved;

[0051] D. Add 3mmol of selenium powder into 3mL of hydrazine hydrate, stir u...

Embodiment 3

[0055] A hollow tubular CoSe 2 / MoSe 2 A method for preparing a composite nanomaterial, comprising the steps of:

[0056] A. Weigh 1mmol cobalt nitrate hexahydrate and 2mmol urea, add 20ml deionized water and stir until dissolved to obtain a clear and transparent solution; transfer the solution to a reaction kettle lined with tetrafluoroethylene, close the reaction kettle and put it into a constant temperature box , at 140°C, heating for 8h;

[0057] B. After the reaction, the cooled liquid in the reaction kettle was centrifuged to separate the solid product, and after the solid product was cleaned several times, it was placed in a vacuum drying oven and dried at 60°C for 6 hours;

[0058] C, weigh 0.2g of the product obtained in step B, add 40mL N, N-dimethylformamide, stir to make it uniformly dispersed; then add 0.7mmol sodium molybdate (Na 2 MoO 4 ), stirred until completely dissolved;

[0059] D. Add 2mmol of selenium powder into 3mL of hydrazine hydrate, stir until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com