Cylindrical coil core explosion-proof lithium ion battery and processing method

A technology of lithium-ion batteries and winding cores, applied in the field of explosion-proof lithium-ion batteries and processing of cylindrical winding cores, can solve the problems of unsatisfactory ion diffusion, poor insulation effect, easy short circuit, etc., and achieve excellent safety performance, low cost, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

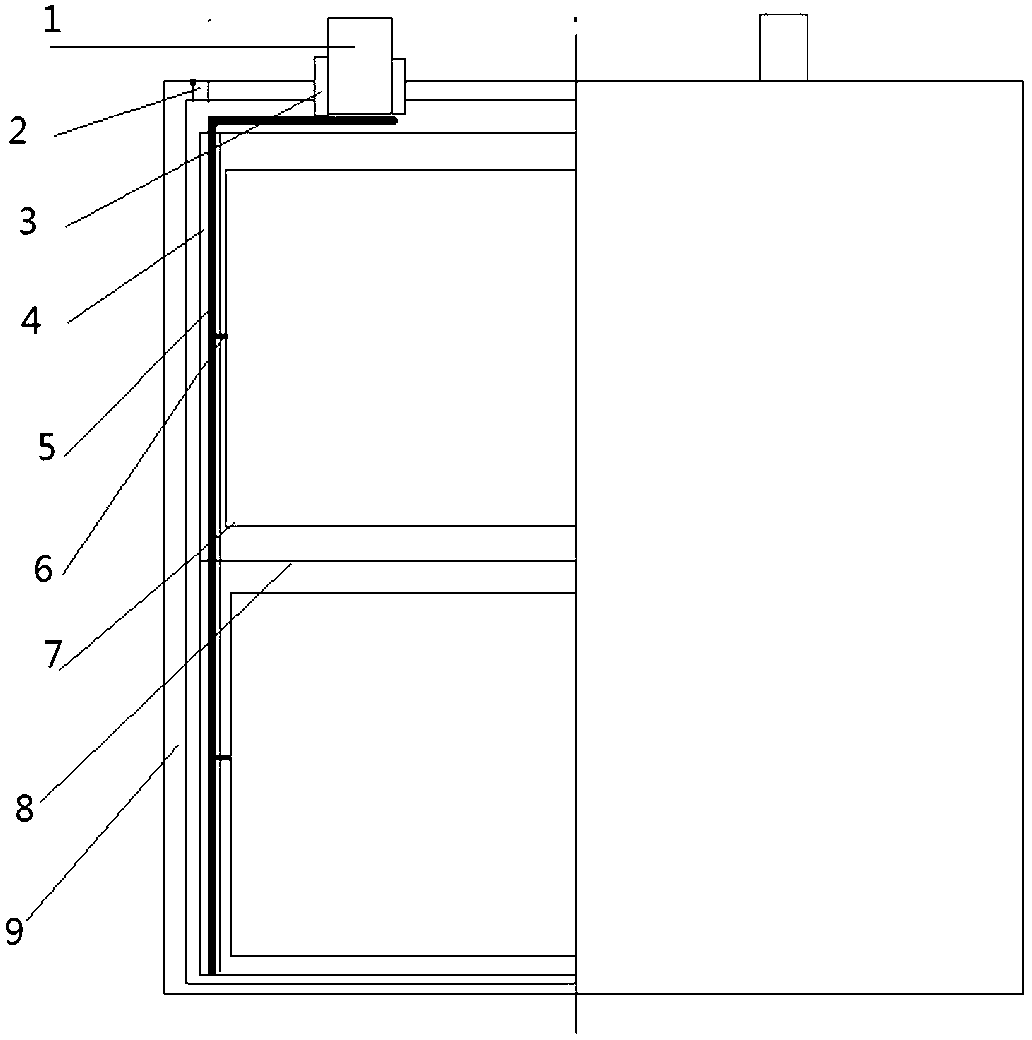

[0026] Embodiment 1 includes a shell, an outer lug 1 , a cylindrical core 7 and an electrolyte. Among them: the cylindrical winding core 7 is composed of two winding core units connected in parallel, the two winding core units are clamped and fixed by two winding core auxiliary modules 8, the outer shell is made of aluminum-plastic film soft packaging bag 9, and two outer poles The ear 1 is sealed and bonded to the opening of the aluminum-plastic film soft packaging bag 9 , and the tabs 6 of all winding core units are connected to the outer tab 1 through the corresponding positive and negative current collectors 5 . The winding core auxiliary module 8 is made of PP material or soft rubber material resistant to electrolyte corrosion, and the preferred number of cylindrical winding cores 7 is 2-4. A tab fastening sheet 3 is prefabricated on the sealing surface of the outer tab 1 and the bag mouth of the aluminum-plastic film outer packaging bag 9, and the material is PP material...

Embodiment 2

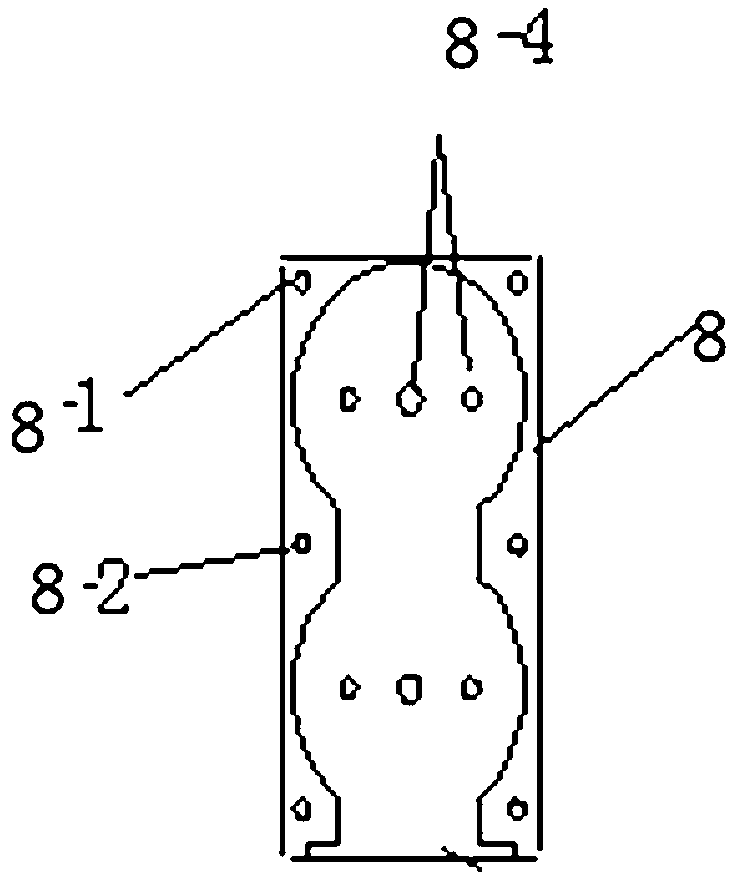

[0027] Embodiment 2, with reference to accompanying drawing 2, on the basis of embodiment 1, described winding core auxiliary mold 8 is the rectangular parallelepiped structure that two pieces of winding core auxiliary modules 8 are combined along the axial direction of winding core, and its inside is provided with A cylindrical groove that is mated with the winding core 7. The two winding core auxiliary modules 8 are provided with mutually plugged protrusions 8-1 and grooves 8-2 on their mating surfaces, and the protrusions and grooves play a role in fixing the two winding core auxiliary modules. The winding core auxiliary module is provided with a through hole or a through groove 8-4 that runs through inside and outside, as a channel for injecting liquid into the battery core. Rolling core auxiliary module 8 is provided with slot 8-3 (corresponding to figure 1 In 4), the positive current collector and the negative current collector 5 are plugged and fixed in the correspondi...

Embodiment 3

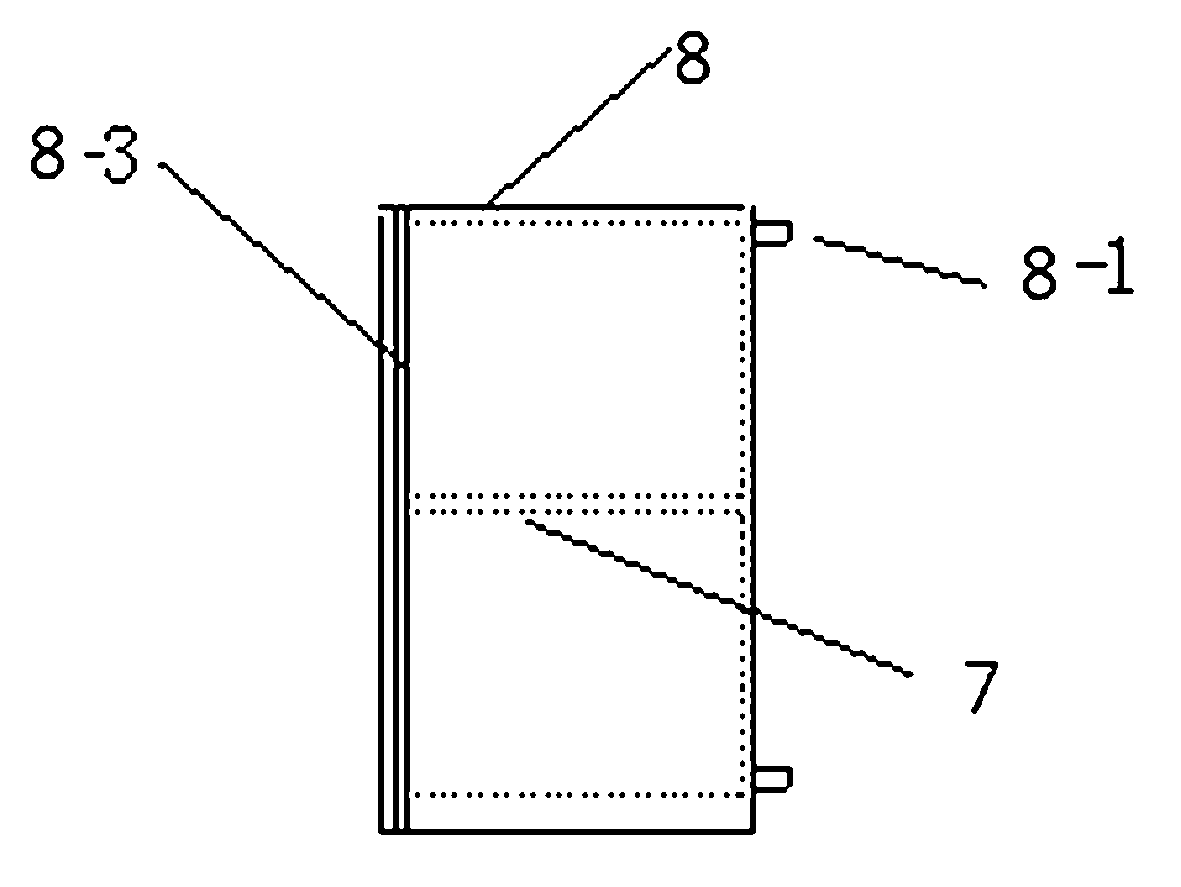

[0028] Embodiment 3, with reference to attached image 3 , in combination with Embodiment 2, the winding core auxiliary module can also adopt a rectangular parallelepiped structure composed of two winding core auxiliary modules 8 along the outer periphery of the winding core 7, and an arc-shaped groove that is plugged and matched with the winding core 7 is provided inside. .

[0029] Preferably, the outer lug is a nickel or aluminum strip folded into an L shape, and the lower end is bent to facilitate welding with the positive and negative current collectors. In order to increase the sealing degree between the outer lug and the aluminum-plastic film packaging material, a layer of glue is applied to the contact between the outer lug and the aluminum-plastic film packaging material. The winding core auxiliary module can protect the winding core from being damaged by external forces such as extrusion force and collision force. At the same time, it also plays the role of auxil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com