Process for producing styrene-butadiene-styrene block copolymer (SBS) modified asphalt

A technology of modified asphalt and production process, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of high price of modifier SBS and increased cost of SBS modified asphalt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

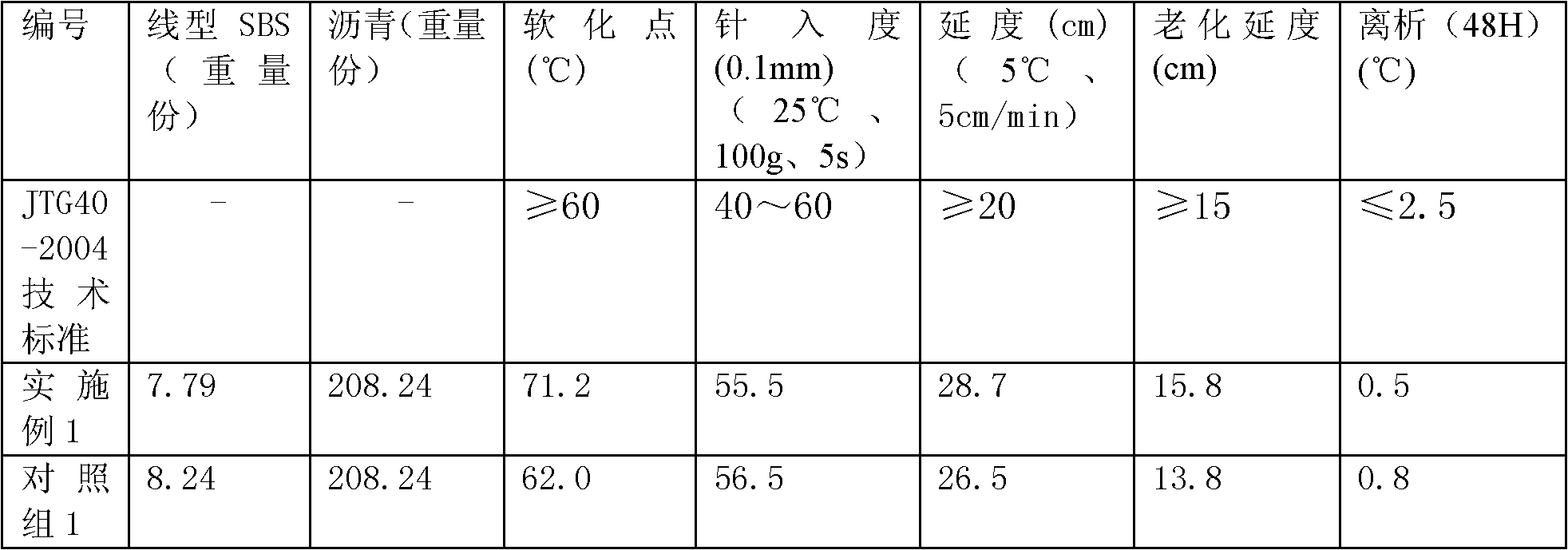

[0029] First, No. 70 base asphalt is heated to 185 °, so that No. 70 base asphalt is in a molten state; secondly, 100 parts by weight of swollen No. 70 base asphalt and 7.79 parts by weight of linear SBS are mixed together and sheared to form a mixture; Add 54.12 parts by weight of swelled No. 70 matrix asphalt and 0.45 parts by weight of stabilizer in the sheared mixture again for a development, the development time is 3.5h, after the completion of the first development, it will be a semi-finished SBS modified asphalt; Add 54.12 parts by weight of swollen No. 70 base asphalt to the developed semi-finished SBS modified asphalt for secondary development. The development time is 0.5h. Linear SBS is 3.6%. Its main technical indicators are shown in Table 1. The control group is the main technical indicators of the SBS modified asphalt made by the existing production process, and the finished SBS modified asphalt contains 3.8% linear SBS.

[0030] Table 1

[0031]

Embodiment 2

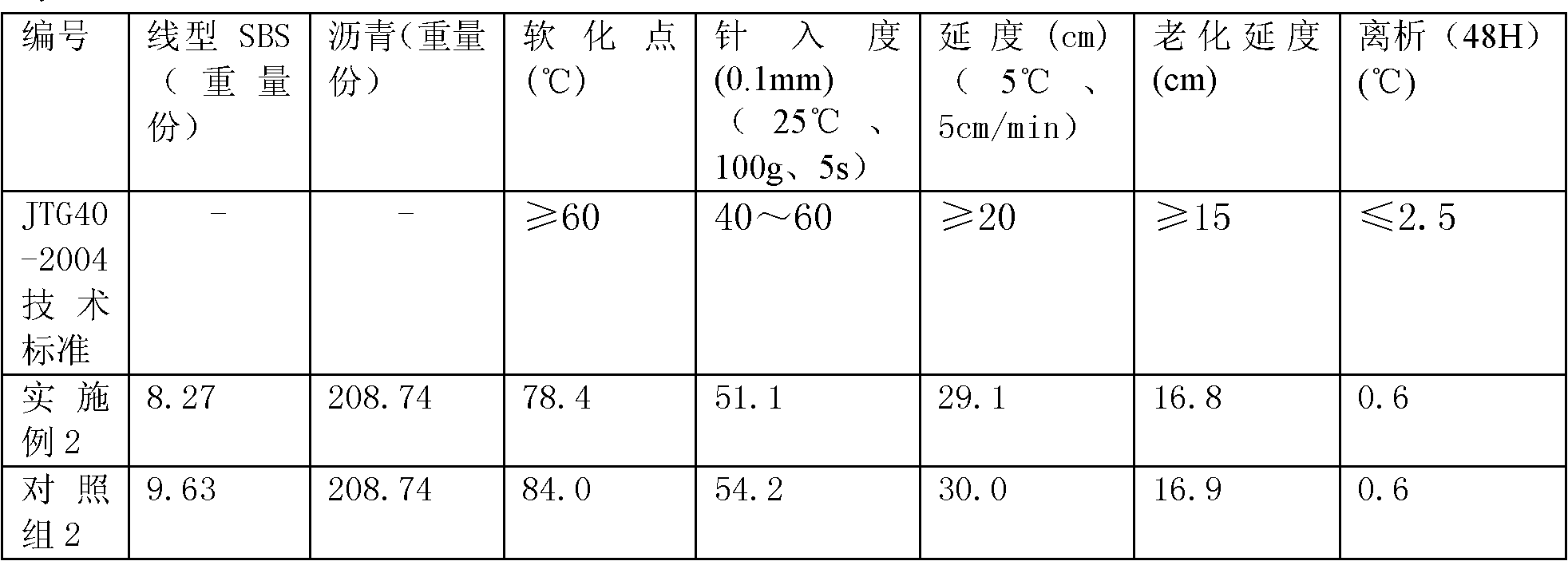

[0033] Firstly, the No. 70 base asphalt is heated to 188°, so that the No. 70 base asphalt is in a molten state; secondly, 100 parts by weight of the swollen No. 70 base asphalt and 8.27 parts by weight of linear SBS are mixed together for shearing to form a mixture ; Add 54.37 parts by weight of swollen base asphalt and 0.46 parts by weight of stabilizer to the mixture after shearing again to develop once again. The development time is 4h, and it will be semi-finished product SBS modified asphalt after the completion of the first development; Add 54.37 parts by weight of swollen No. 70 base asphalt to the developed semi-finished SBS modified asphalt for secondary development. Type SBS is 3.8%. Its main technical indicators are shown in Table 2, in which the control group is the main technical indicators of SBS modified asphalt produced by one-time development of the existing production process, and the finished SBS modified asphalt contains 4.4% linear SBS.

[0034] Table 2 ...

Embodiment 3

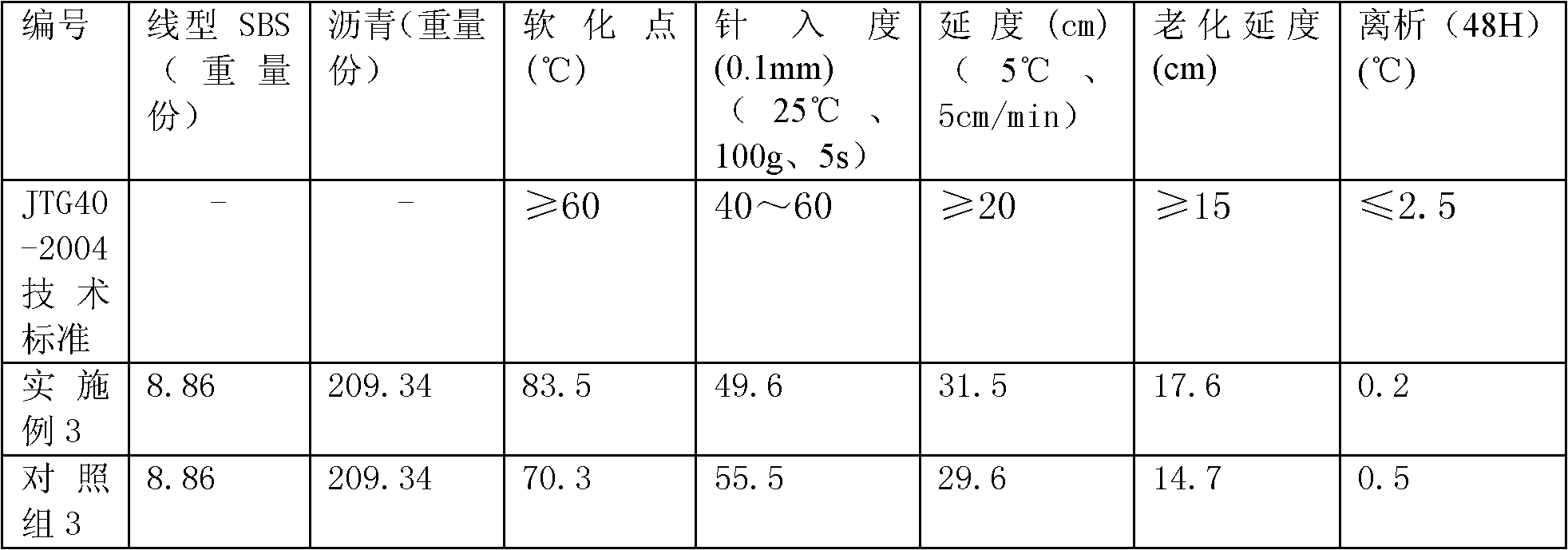

[0037] Firstly, No. 70 base asphalt is heated to 190°, so that No. 70 base asphalt is in a molten state; secondly, 100 parts by weight of swollen No. 70 base asphalt and 8.86 parts by weight of linear SBS are mixed together for shearing to form a mixture ; Add 54.67 parts by weight of swollen base asphalt and 0.49 parts by weight of stabilizer to the mixture after shearing again to develop once again. The development time is 4.2h, and it will be semi-finished SBS modified asphalt after the completion of the first development; Add 54.67 parts by weight of swollen No. 70 base asphalt to the semi-finished SBS modified asphalt after the primary development for secondary development, and the development time is 1.2 hours; Contains 4.0% linear SBS. Its main technical indicators are shown in Table 3, wherein the control group is the main technical indicators of SBS modified asphalt produced by one-time development of the existing production process, and the finished SBS modified asph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com