Bone porcelain with high resistance of heat shocks and production method thereof

A bone china, high heat resistance technology, applied in other household appliances, clay products, household appliances and other directions, can solve problems such as poor thermal shock resistance, achieve good toughness and mechanical properties, realize industrialization, and scientific and reasonable production steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

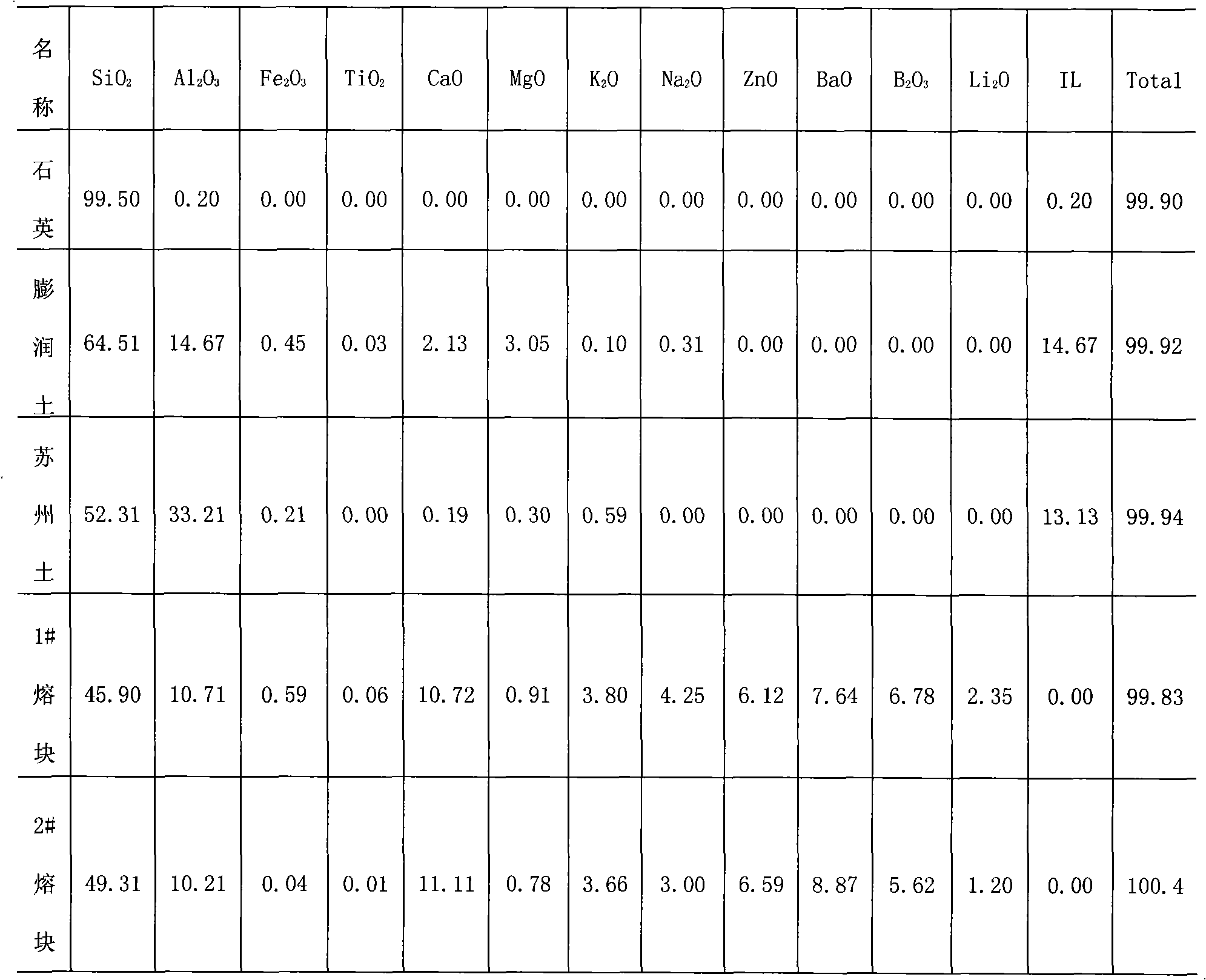

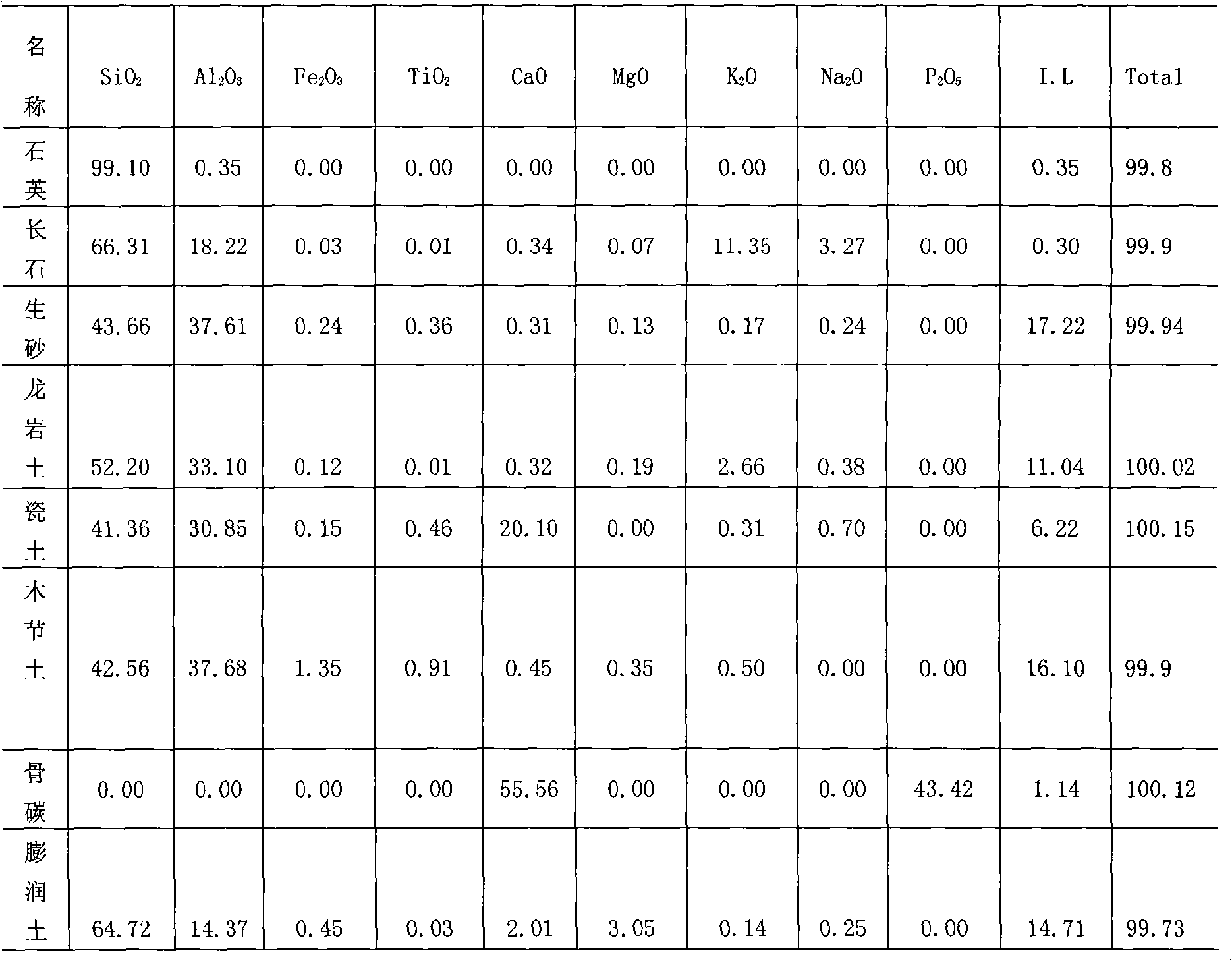

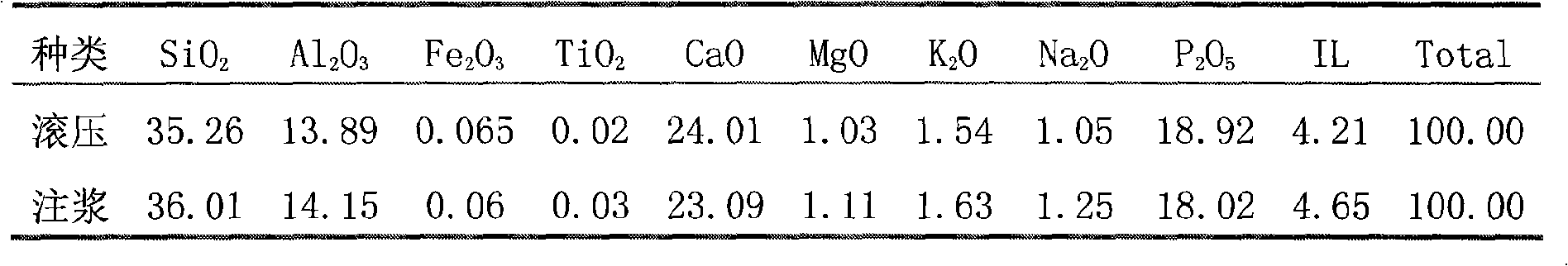

[0024] Example 1: The raw material composition and weight percentage content of the bone china blank are: quartz 10, feldspar 10, raw sand 14, Longyan clay 4, china clay 8, wood joint clay 4, bone carbon 42, and bentonite 8.

Embodiment 2

[0025] Example 2: The raw material composition and weight percentage content of the bone china blanks are: 9 quartz, 7 feldspar, 11 raw sand, 7 Longyan clay, 7 porcelain clay, 4 wood joint clay, 46 bone carbon, and 7 bentonite.

Embodiment 3

[0026] Example 3: The raw material composition and weight percentage content of the bone china blank are: quartz 12, feldspar 8, raw sand 14, Longyan clay 4, china clay 5, wood joint clay 5, bone carbon 42, and bentonite 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com