Infrared filter with broadband of 3.65 to 5 microns, and manufacturing method for infrared filter

A technology for an infrared filter and a manufacturing method, which are applied in the field of 3.65-micron to 5-micron broadband infrared filters and their manufacture, can solve the problems of poor precision and low signal-to-noise ratio, achieve excellent performance, and meet the requirements of sensitivity and precision , The effect of stable and mature process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

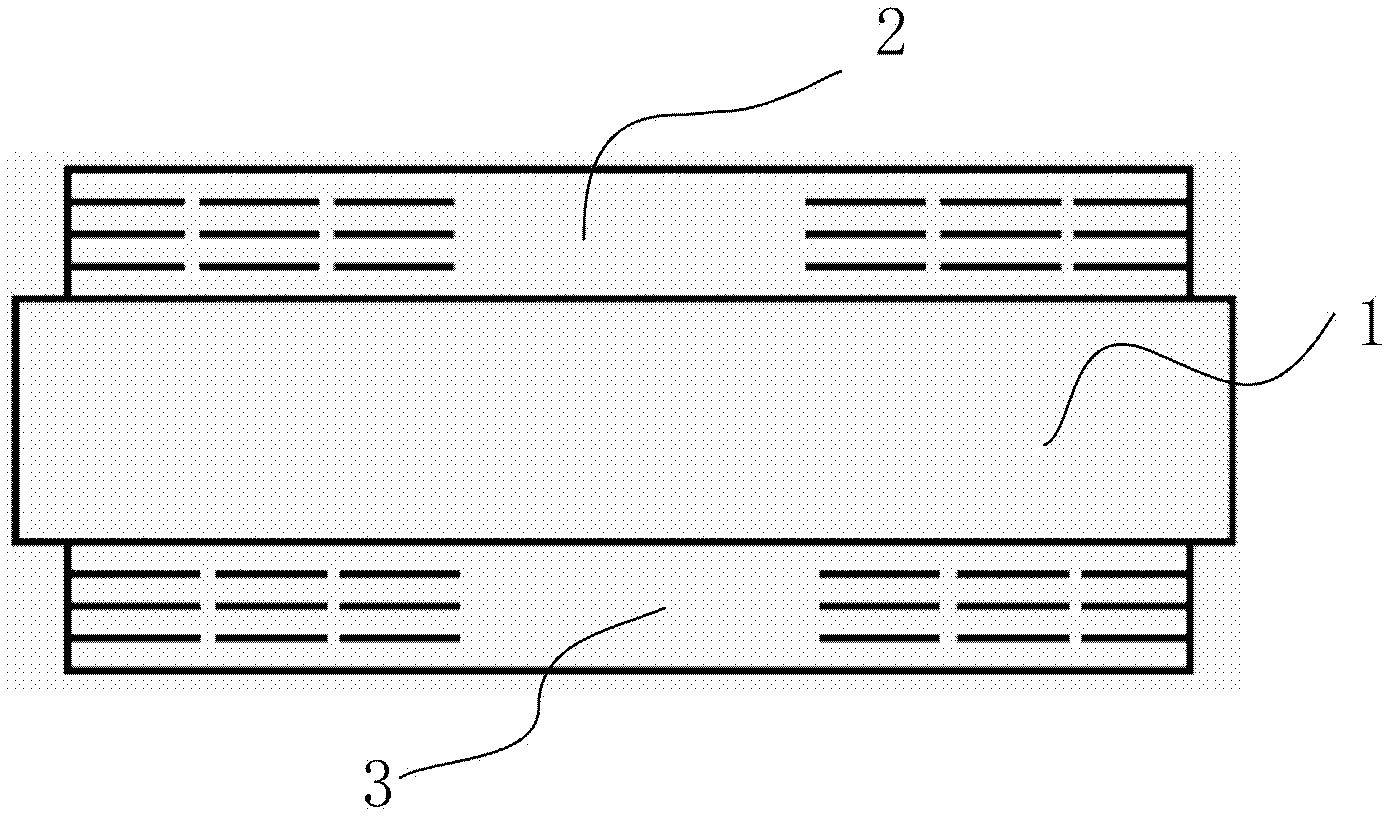

[0021] like figure 1 As shown, the present embodiment provides a 3.65 micron to 5 micron broadband infrared filter,

[0022] (1) Single-crystal germanium Ge with a size of Φ18×1.0mm is used as the substrate 1, the surface aperture N≤5, the local aperture ΔN≤0.5, the parallelism θ≤1', and the surface finish is better than 60 / 40;

[0023] (2) Silicon monoxide SiO and single crystal germanium Ge are selected as the coating material, and multi-layer interference films are respectively deposited on the two surfaces of the substrate;

[0024] (3) The design of the first mask series interference film 2: Sub|1.33(.5HL.5H)5 3.39(.5LH.5L)5|Air

[0025] The second mask is interference film 3. Design and use: Sub|0.92(.5HL.5H) 3 1.1(.5HL.5H) 4 |Air

[0026] The corresponding meanings in the film system are: Sub is the substrate, Air is air, H is λc / 4 single crystal germanium film, L is λc / 4 silicon monoxide film, λc=2μm, and the number in the structure is the thickness of the film l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com