External-heating double-position spiral drying roasting kiln for ex-situ remediation of soil

An ex-situ repair and spiral technology is applied in the field of drying and roasting kilns and soil ex-situ repairing external heat two-position spiral drying and roasting kilns. The effect of reducing waste, reducing the extension of construction period, and high thermal desorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

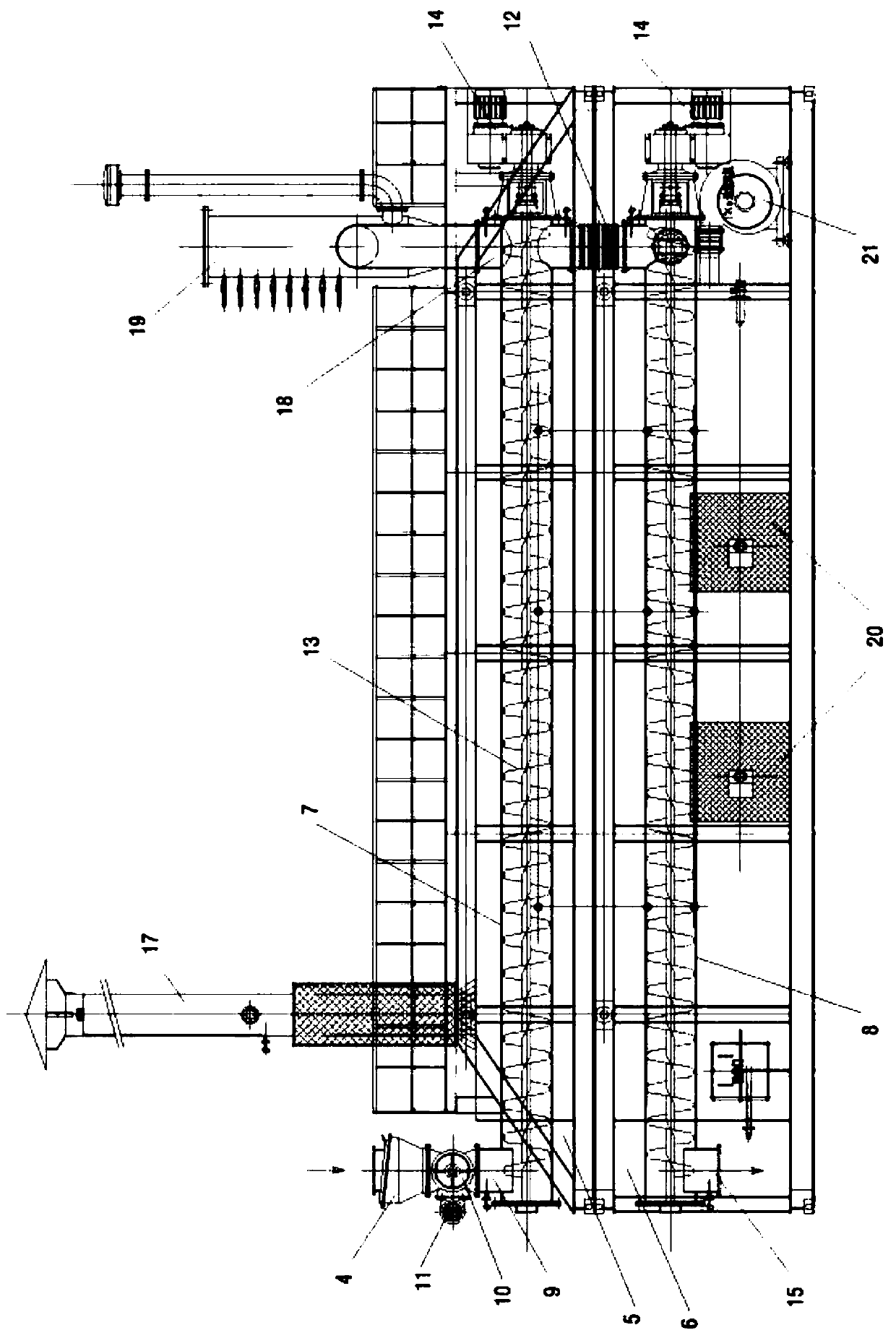

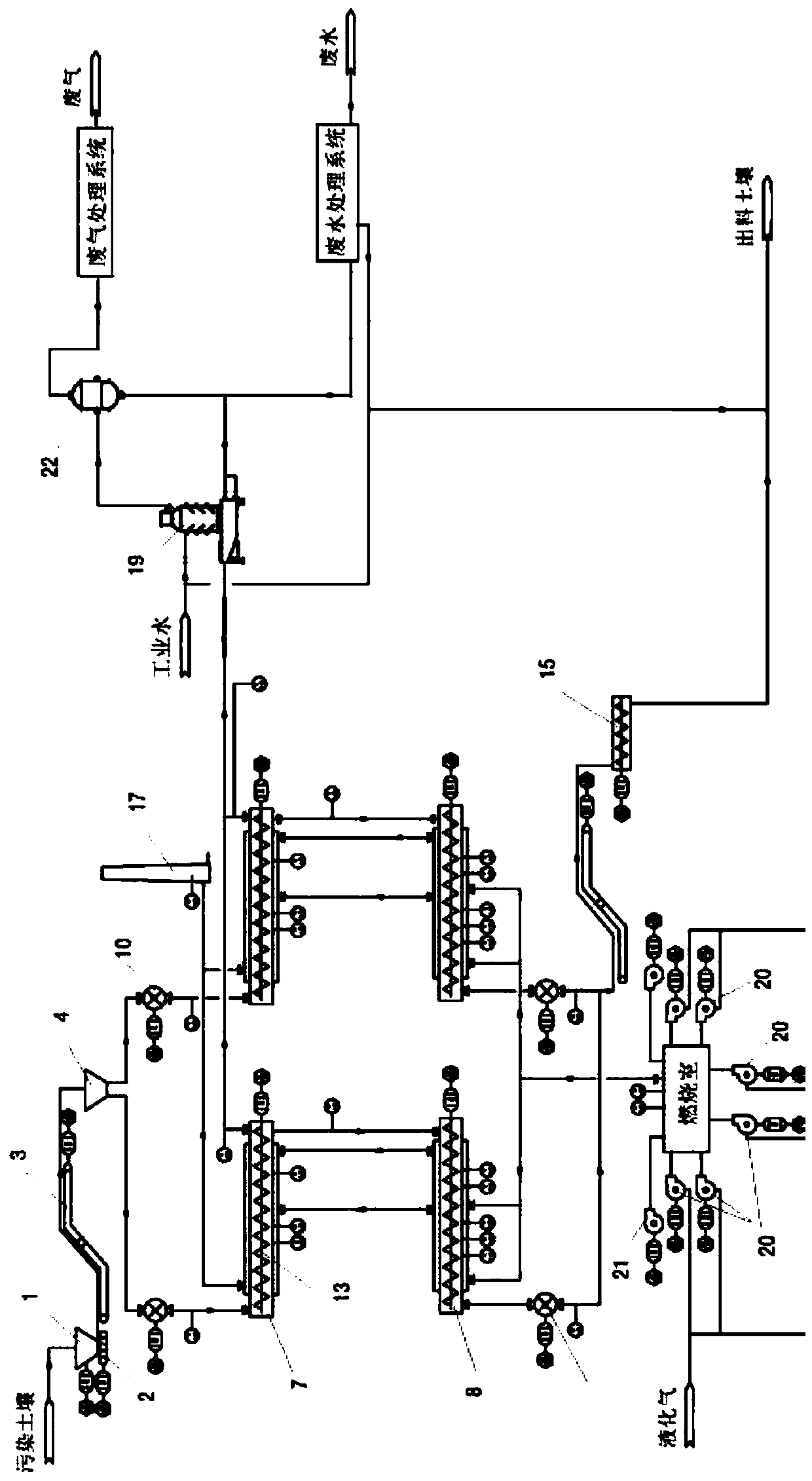

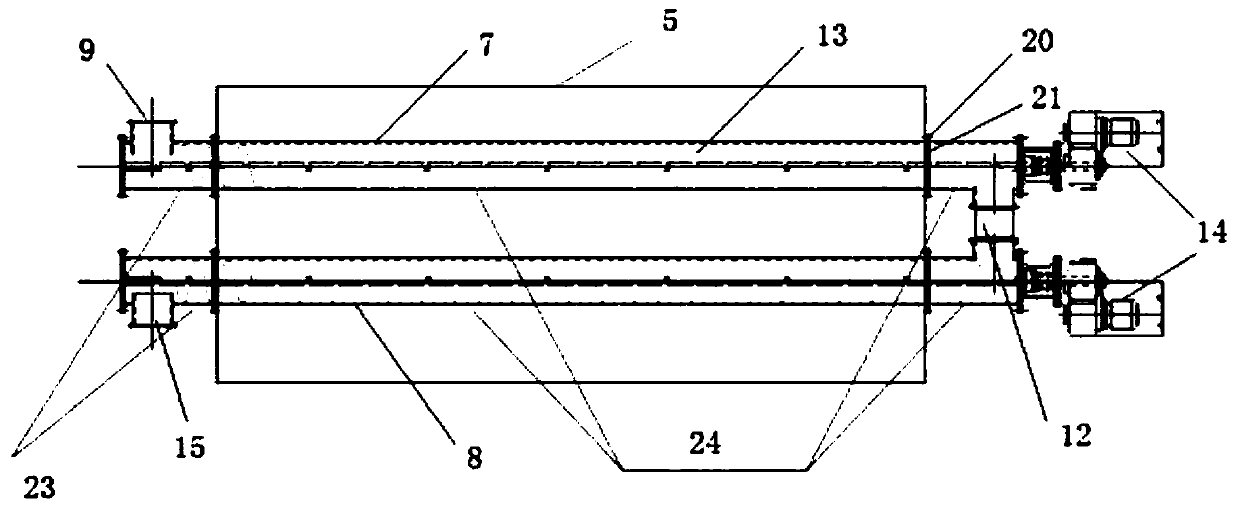

[0033] Such as figure 1 , figure 2 As shown, the present invention is a dual-position spiral drying and roasting kiln for ectopic repair of soil, which includes a heating furnace body. The heating furnace body is composed of an upper furnace body 5 and a lower furnace body 6 connected by bolts. The top of the lower furnace body 6 is connected to the bottom of the upper furnace body 5; the upper furnace body 5 is provided with two upper furnace tubes 7, and the lower furnace body 6 is provided with two lower furnace tubes 8, namely the upper furnace tube 7 and the lower furnace tube 8 There are two each, and there are four furnace tubes in total; the two upper furnace tubes 7 (drying area) are made of 16Mn boiler steel seamless steel pipes; the two lower furnace tubes 8 (roasting area) are made of SUS321 heat-resistant stainless steel seamless steel pipes.

[0034] Be provided with feed inlet 9 on upper furnace tube 7 left side tops, be provided with rotary vane feeder 10 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com