Dispensing machine for producing LEDs (Light Emitting Diodes)

A technology of dispensing machine and teaching board, which is applied in the direction of coating, liquid coating device on the surface, etc. It can solve the problems of reducing the work efficiency of operators and increasing the labor intensity of operators, so as to prevent uneven heating and expand the application range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

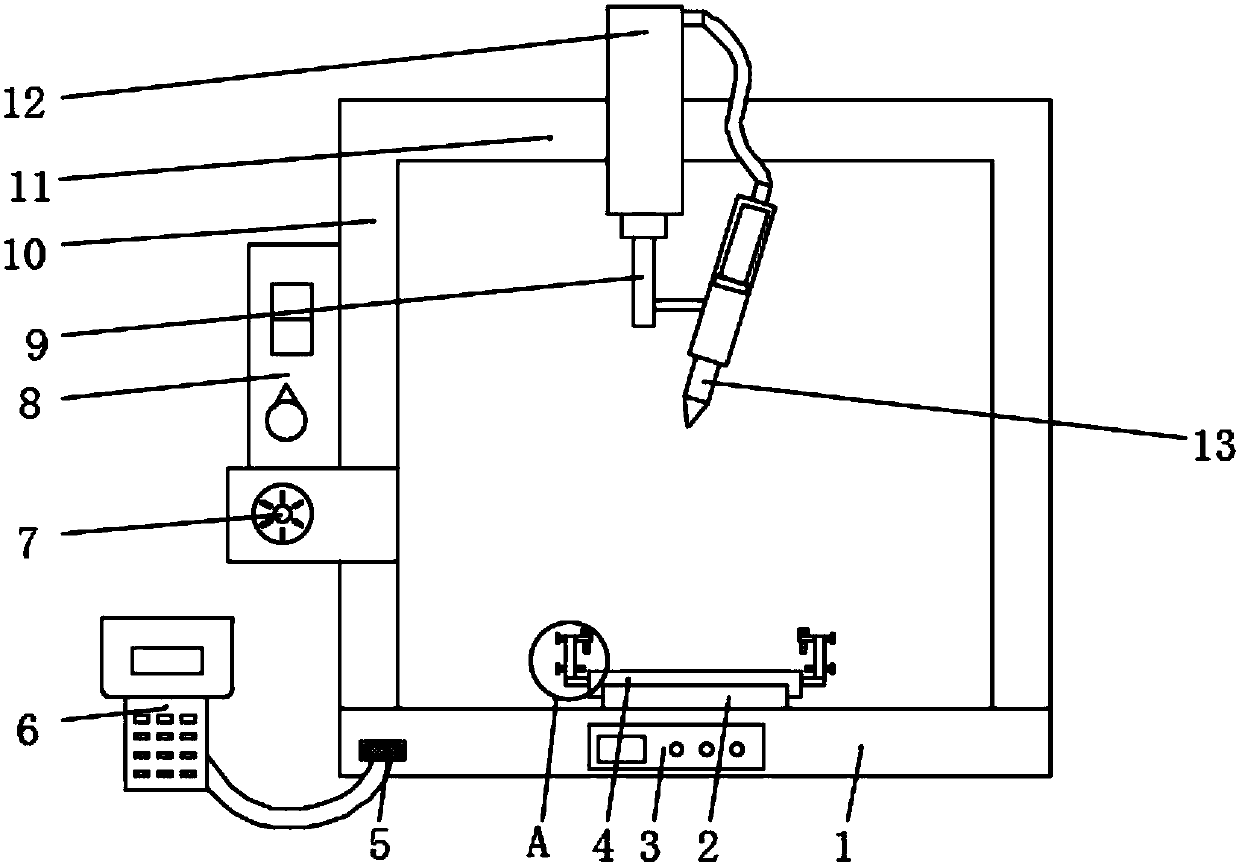

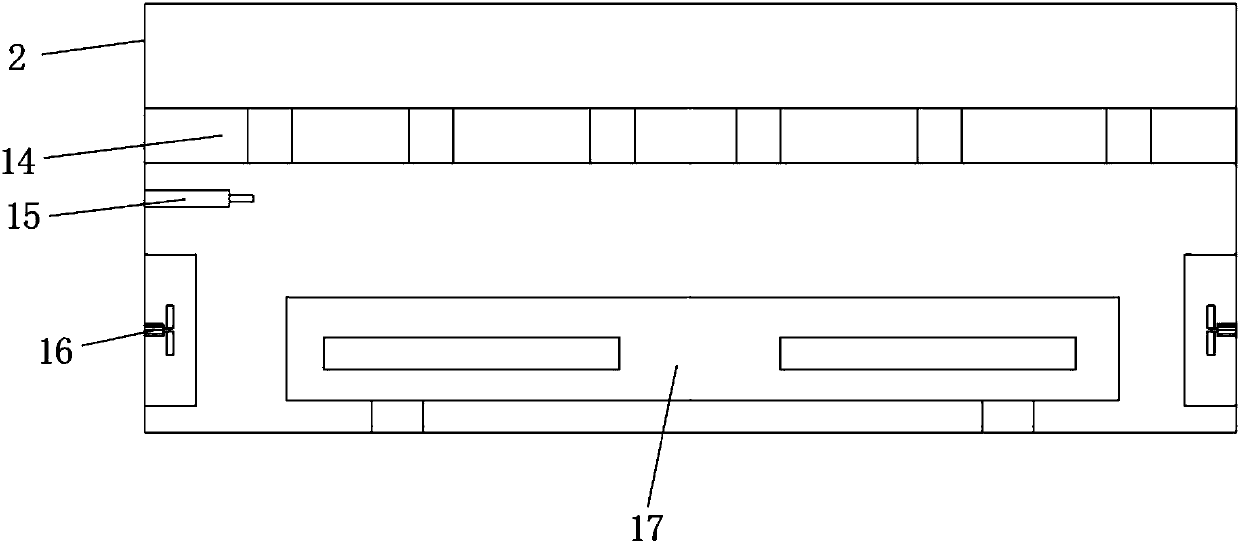

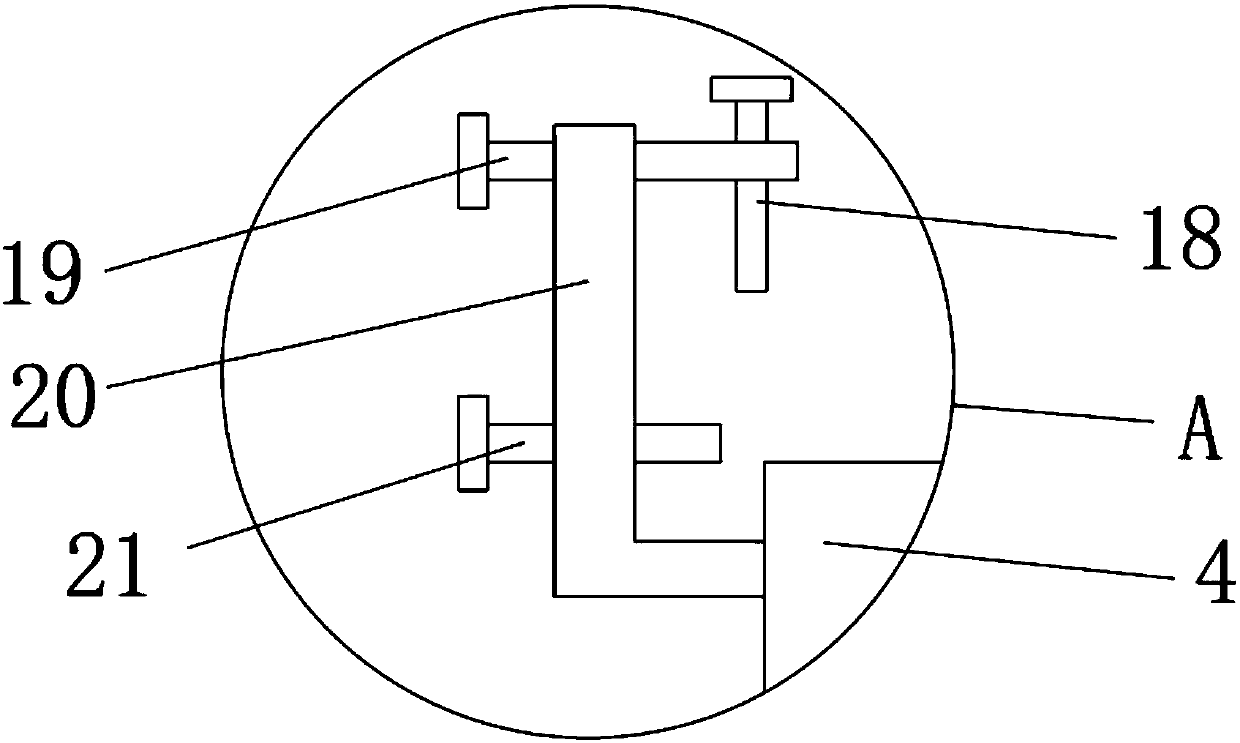

[0022] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a dispensing machine for LED production, including a base 1, a temperature controller 3 is arranged in the middle of the front surface of the base 1, and a front surface of the base 1 is close to a part of the temperature controller 3 The side position is provided with a city teaching board interface 5, and the city teaching board interface 5 is fixedly connected with a city teaching board 6 through a wire. A temperature sensor 15 is provided on the inner side wall of the platform 2 near the upper position of the motor 16, and a wind outlet baffle 14 is arranged on the inner side wall of the bearing platform 2 near the upper position of the temperature sensor 15, and the bottom end of the bearing platform 2 is provided with a The heating plate 17, the upper surface of the platform 2 is provided with a Y-axis plate 4, and both ends of the Y-axis plate 4 are provided with a fixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com