Electric heating type U-shaped hot material heat preservation conveying groove and spiral heat preservation conveyor for transferring hot materials

A conveying trough, electric heating technology, applied in the field of U-shaped heat preservation conveying trough, can solve the problems of limited number of characters, lack of heating and heat preservation function of U-shaped trough, and cannot meet the needs of special screw conveyor heat preservation and heat transfer materials, etc., to achieve Good effect, guaranteed drying effect, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

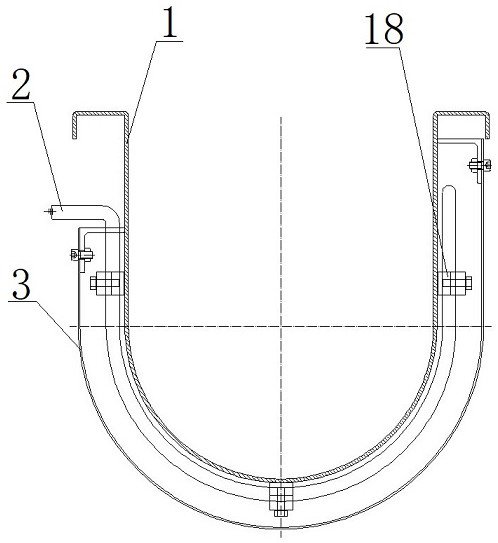

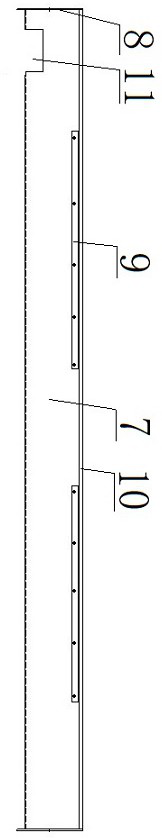

[0028]An electric heating U-shaped heat preservation conveying trough 21 (abbreviation: U-shaped heat preservation conveying trough), the main point of the innovative overall implementation scheme is to improve the existing single-layer U-shaped normal temperature conveying trough into a coated insulation layer The electric heating U-shaped heat insulation conveying tank 21 includes U-shaped feeding chute 1, electric heating insulation layer 3, tank cover parts, and sealing groove end plate 22; mainly to add electric heating insulation layer, including electric heating pipe 2, U-shaped insulation layer Layer 3; the electric heating insulation layer covers the U-shaped feeding chute 1, the sealing groove end plates 22 are welded on both ends of the U-shaped feeding chute 1, and the trough cover parts cover the U-shaped feeding chute 1 to form a U-shaped heat preservation conveying Slot 21; while the screw conveyor conveys the hot material in the U-shaped feeding trough 21, the e...

Embodiment 2

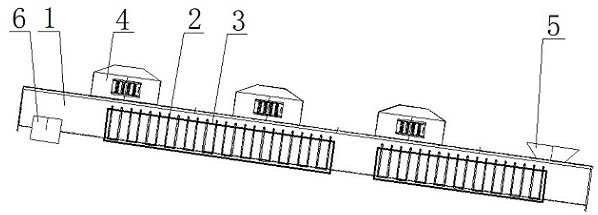

[0036] A spiral heat preservation conveyor for transferring hot material (abbreviation: spiral heat preservation conveyor), which is to transfer the hot material (hot filter cake) of a filter press to a spiral heat preservation conveyor of a filter cake dryer, using the electric heating U type provided by the present invention. 21-shaped thermal insulation conveying trough 21 (abbreviation: U-shaped thermal insulation conveyor); the spiral thermal insulation conveyor is mainly composed of a screw drive device, a shaft screw device, and a U-shaped thermal insulation conveyor trough 21; It is suitable for high output non-viscous non-winding hot materials within 70 meters. The technical part shared by the present invention and the prior art is manufactured in accordance with the current standard "Screw Conveyor" JB / T 7679 of my country's machinery industry.

[0037] The screw drive device includes a motor drive device, a machine head coupling, and a common base 23; the set motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com