Image sensor package utilizing a removable protection film and method of making the same

An image sensor and protective film technology, which is applied in the field of image sensor packaging structure using removable protective film, can solve the problems of pollution, particle removal, etc., achieve high yield, and promote the effect of simplification of procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail with preferred embodiments and accompanying drawings. However, those skilled in the art will appreciate that the preferred embodiments of the present invention are described by way of illustration rather than limiting the claims of the present invention. The present invention is widely practiced in other embodiments than the preferred embodiment explicitly described herein, and the scope of the present invention is not particularly limited except as expressly defined in the appended claims.

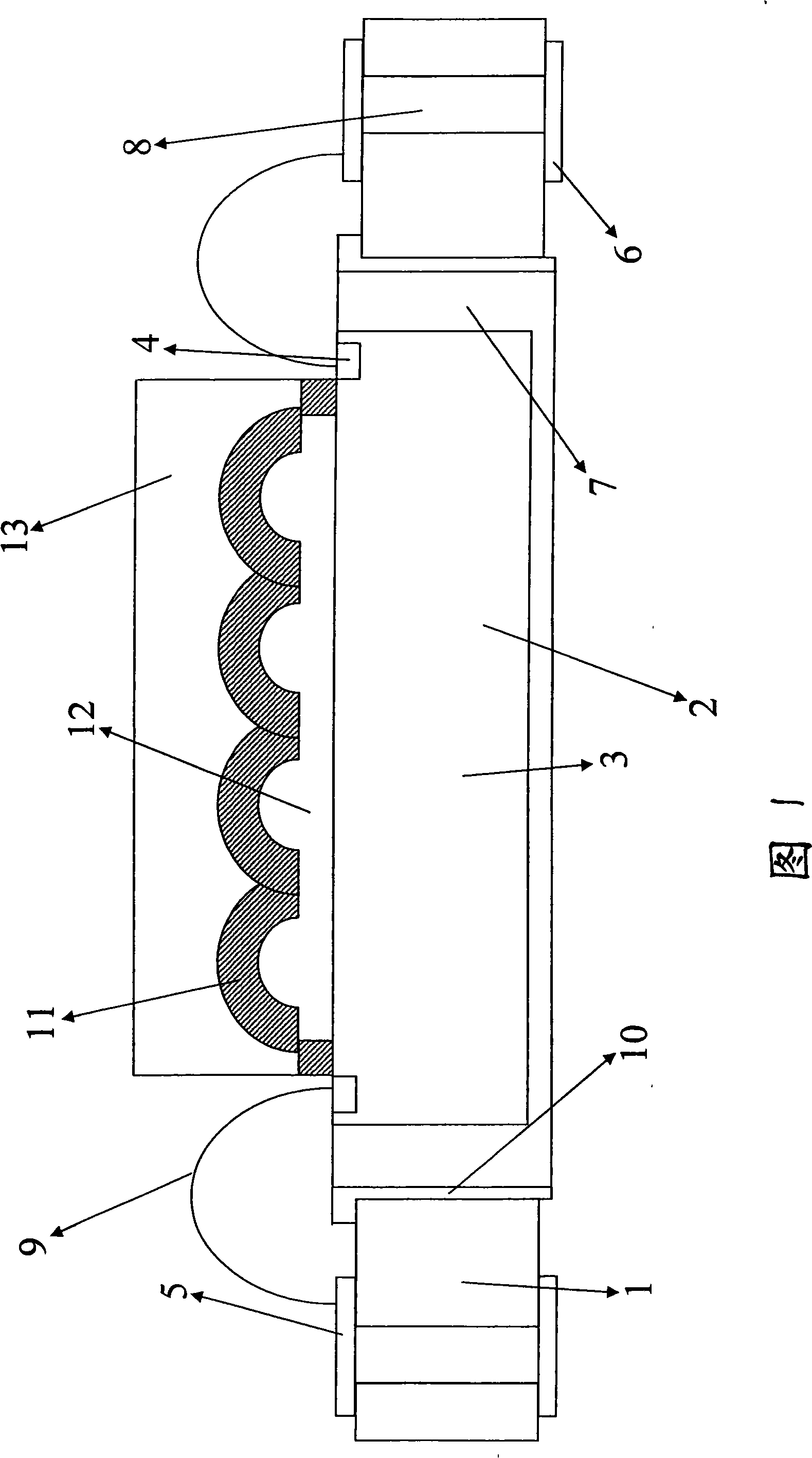

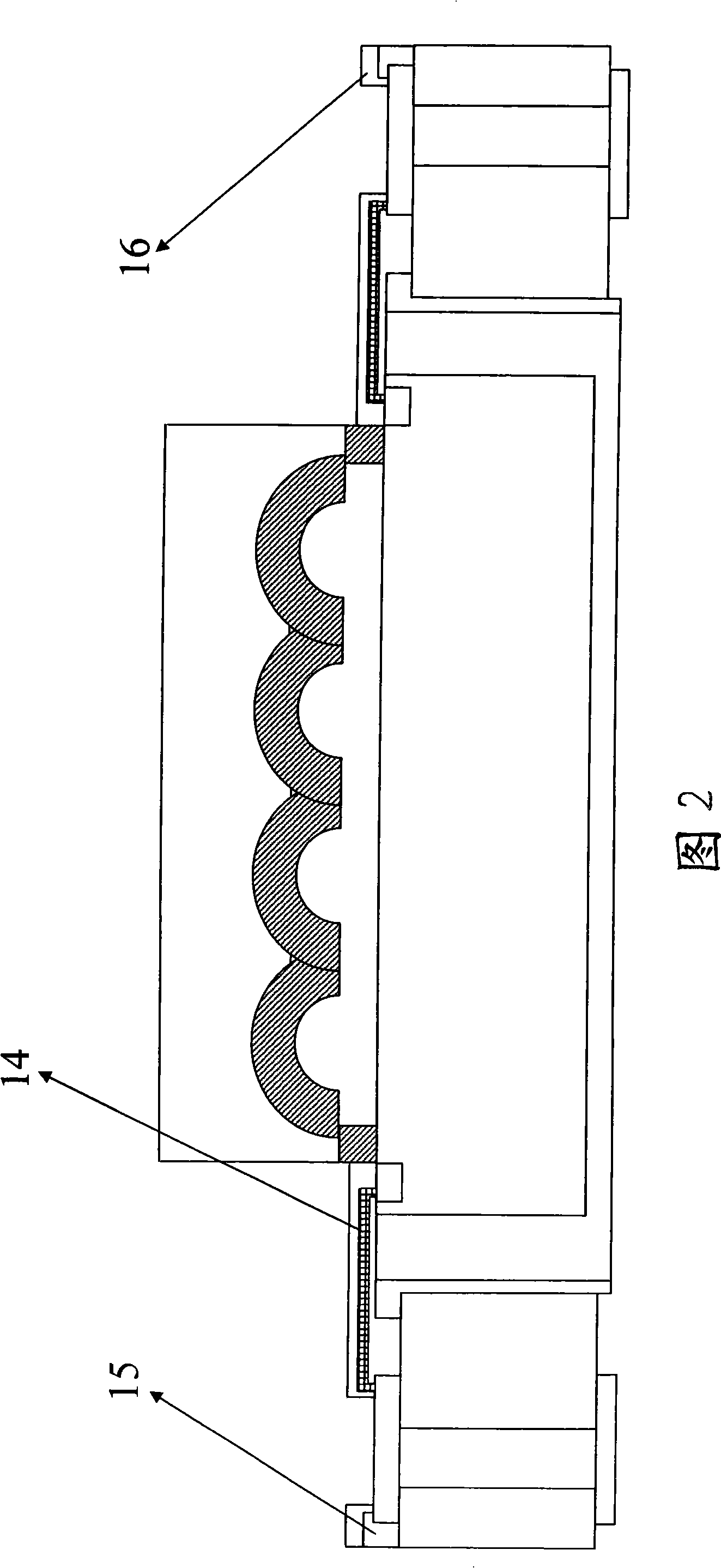

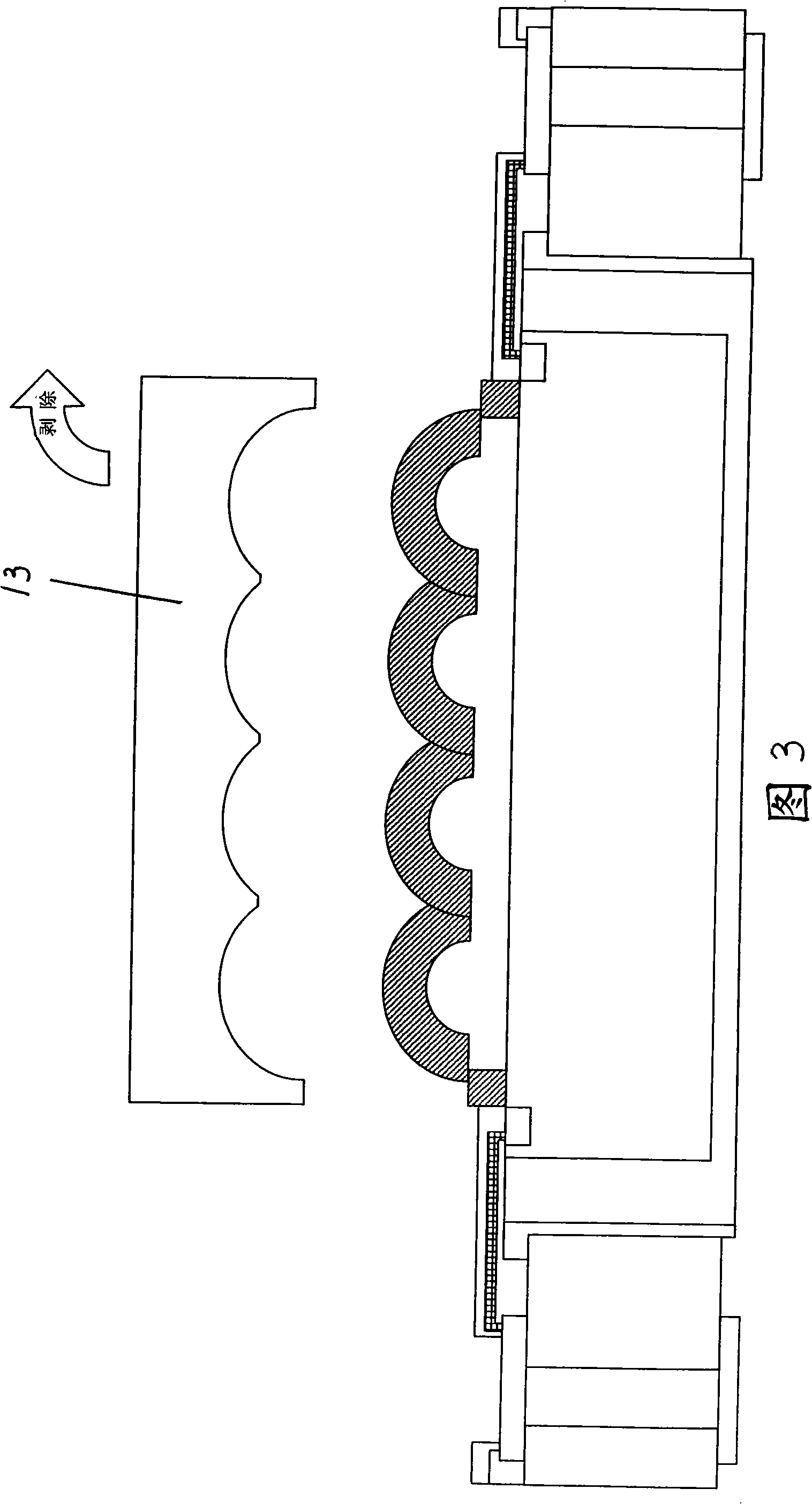

[0042] The invention discloses an image sensor packaging structure using a removable protective film. FIG. 1 is a schematic cross-sectional view illustrating a silicon wafer package of an image sensor according to an embodiment of the present invention. As shown in FIG. 1 , the silicon wafer package structure includes a substrate 1 having a die receiving hole 2 formed therein for receiving a die 3 . The width dimension of die rece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com