Wet tissue heater convenient to operate

An easy-to-operate heater technology, applied in the shape of heating elements, household appliances, etc., can solve the problems of complex and inconvenient operation of wet wipe heaters, and achieve the effect of convenient operation, simple and convenient operation, labor-saving, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

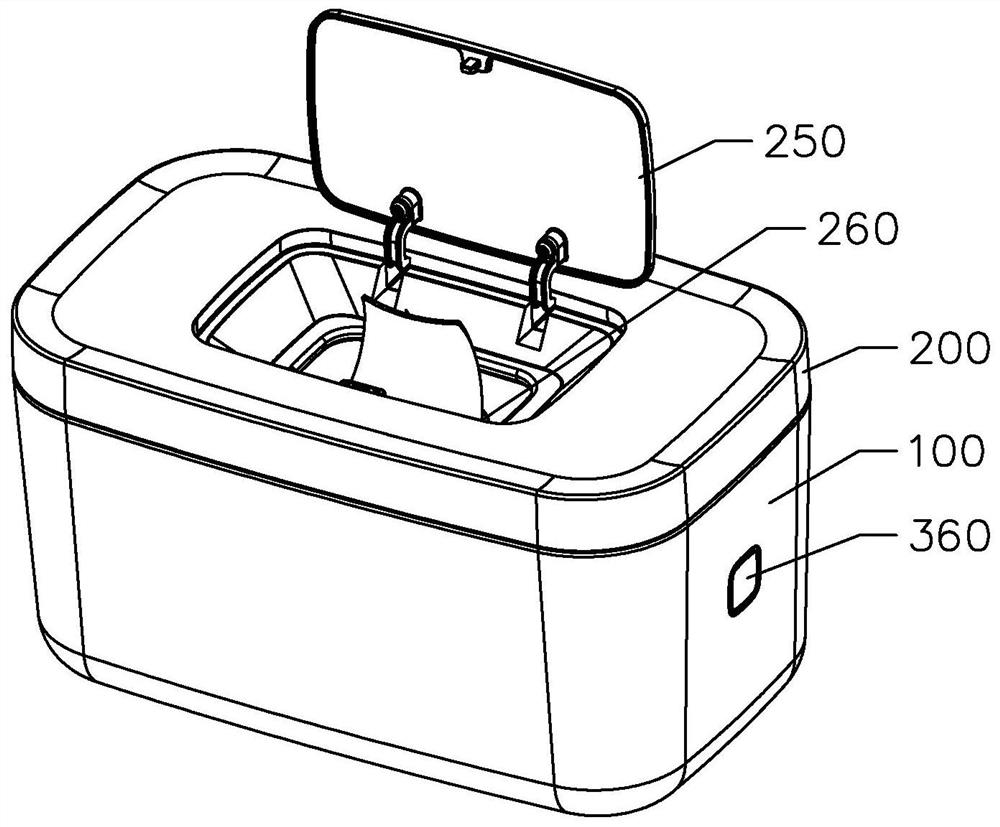

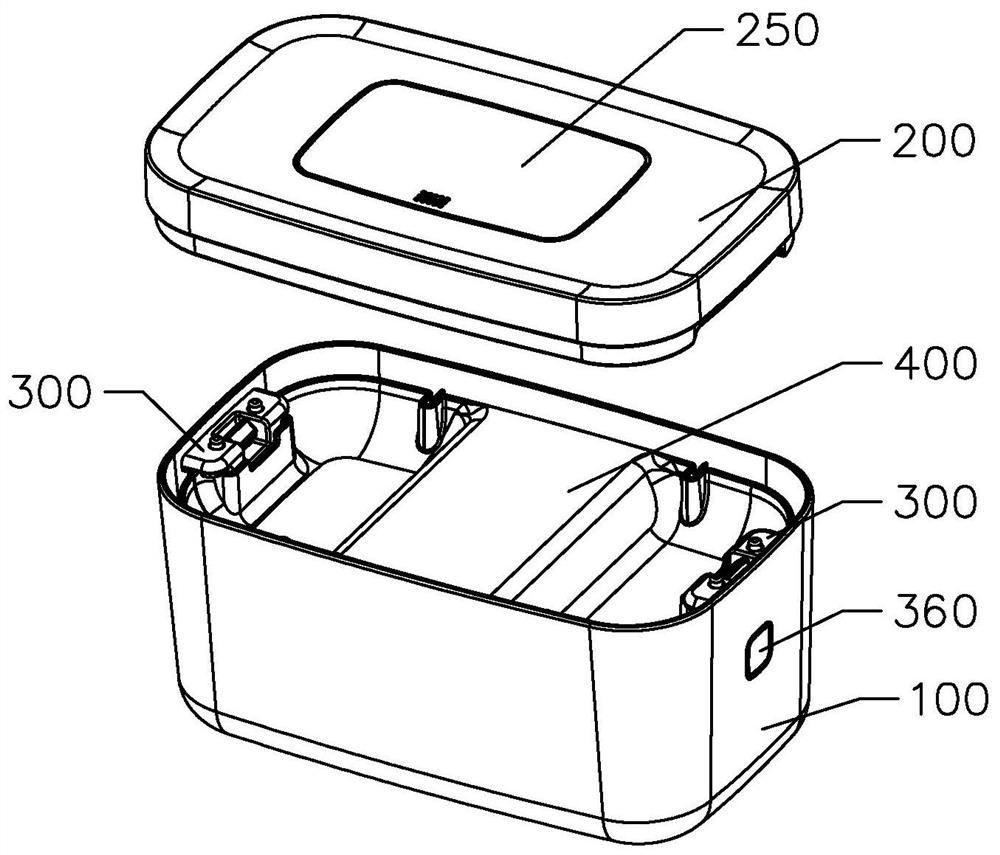

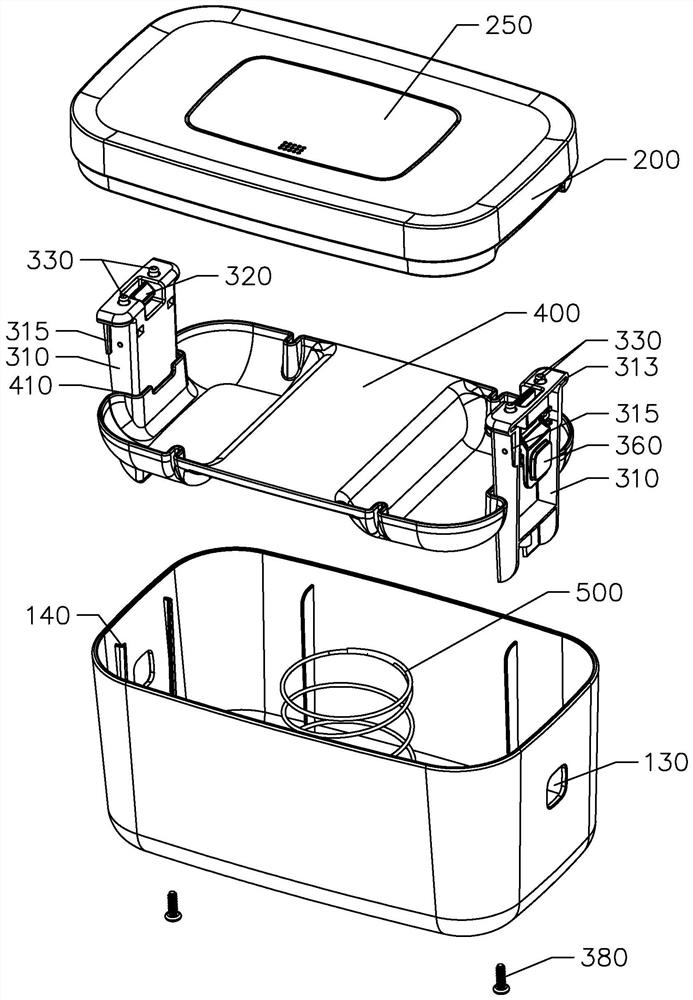

[0046] like Figure 1 to Figure 9 As shown, the present invention provides an easy-to-operate wet wipe heater, which includes a box body 100 and a cover body 200. The box body 100 is used to accommodate wet wipes. The cover body 200 is located above the box body and covers the wet wipes in the box body. The cover body 200 is provided with a first heating element, and the box body 100 and the cover body 200 are connected through a connection structure 300. There are two connection structures 300 and are located on both sides of the box body 100 respectively. Outlet 260, and is provided with flip cover 250, and flip cover 250 is positioned at the top of wet tissue take-out outlet, and is connected to the cover body in rotation, so as to open or close the wet tissue take-out outlet. The box body 100 is provided with a lifting plate 400, and the lower end of the lifting plate 400 is provided with a lifting spring 500, and the lifting spring 500 drives the lifting plate 400 to move...

Embodiment 2

[0064] The main difference between this embodiment and Embodiment 1 is that the wet tissue package is fixed by the elastic band.

[0065] like Figure 10 As shown, the lower end surface of the cover body 200 is provided with an elastic belt 220, and the wet tissue pack is directly pressed tightly on the lower end surface of the cover body by the elastic belt instead of the lifting plate and the lifting spring. The advantage of such setting is that the structure of the wet tissue heater is simplified, the production cost is reduced, and the wet tissue heater is more portable.

Embodiment 3

[0067] The main difference between this embodiment and the second embodiment is that the box body includes an inner box body and an outer box body.

[0068] like Figure 11 and Figure 12 As shown, the box includes an inner box 110 and an outer box 120 , and the connection structure 300 is located between the inner box 110 and the outer box 120 . The advantage of this setting is that the connection structure cannot be seen from inside the box body, and the appearance of the wet wipe heater is more neat and beautiful.

[0069] In this embodiment, the bracket shell and the inner box body 110 are integrally formed by injection molding, so that the connection between the bracket shell and the inner box body is relatively reliable, and no additional connection structure is required, making the structure simpler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com