High-pressure vacuum thermal shrinkage furnace for corrugated stainless steel hose cladding and corrugated stainless steel hose cladding method

A corrugated hose and stainless steel technology, which is applied in the field of high-pressure vacuum heat shrinking furnace, can solve the problems of poor fluidity of PVC material, corrosion of stainless steel corrugated hose, and limited application range, etc., and achieves low cost, good effect, simple and convenient operation and labor saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

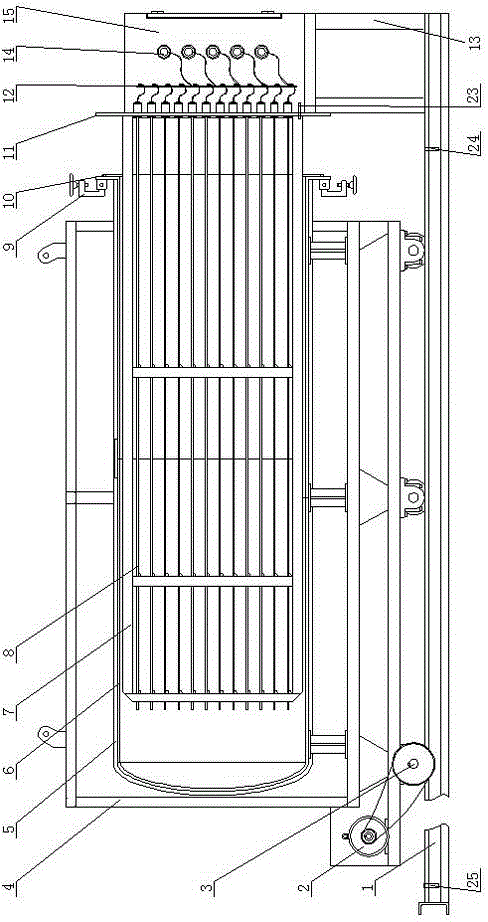

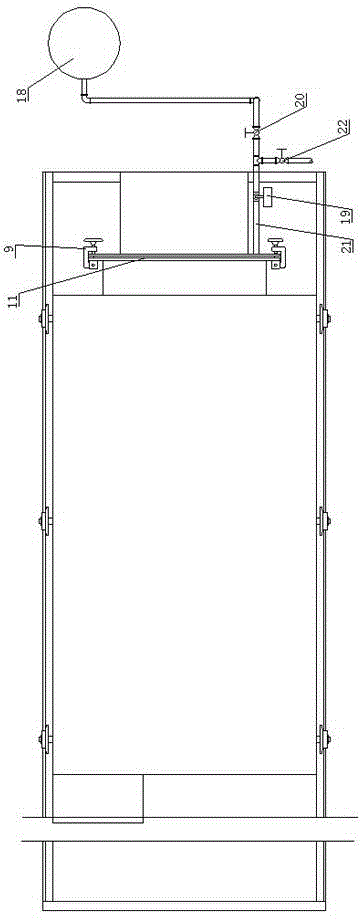

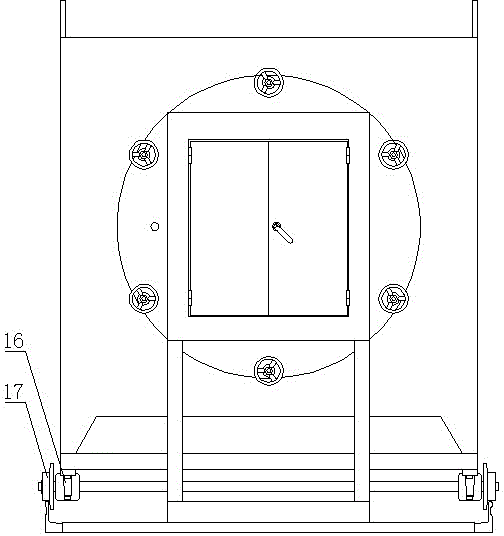

[0016] See Figure 1 ~ Figure 3 , The high-pressure vacuum heat shrinking furnace for coating stainless steel corrugated hose in the embodiment of the present invention includes a guide rail assembly 1, a transmission mechanism 2, a box body 4, an insulating cotton 5, an inner tank 6, a fixing frame assembly 7, an electric heating tube assembly 8, Clamping mechanism assembly 9, sealing strip 10, fixed door 11, electrical box 15, guide wheel assembly 17, vacuum device, transmission mechanism 2 is installed on box 4, and insulation cotton 5 and inner liner are installed in box 4 6. Insulation cotton 5 wraps (covers) the inner tank 6, the box body 4 is slidably mounted on the guide rail assembly 1 through the guide wheel assembly 17, the transmission mechanism 2 is connected to the guide wheel assembly 17, and the guide rail assembly 1 is fixedly connected to the bracket 13 , A fixed door 11 and an electrical box 15 are installed on the bracket 13, a vacuum device, a temperature s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com