Tobacco loading process in intensive curing barn and its semi-automatic reversing tobacco loading operation table and tobacco transporting trolley

一种密集烤房、半自动的技术,应用在机动车、手推车、多轴手推车等方向,能够解决影响专利设备使用和推广、增加烟农劳动强度等问题,达到提高设备烘烤质量、提供装烟烤烟效率、工艺步骤简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

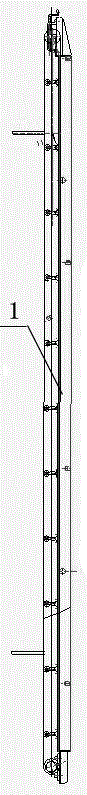

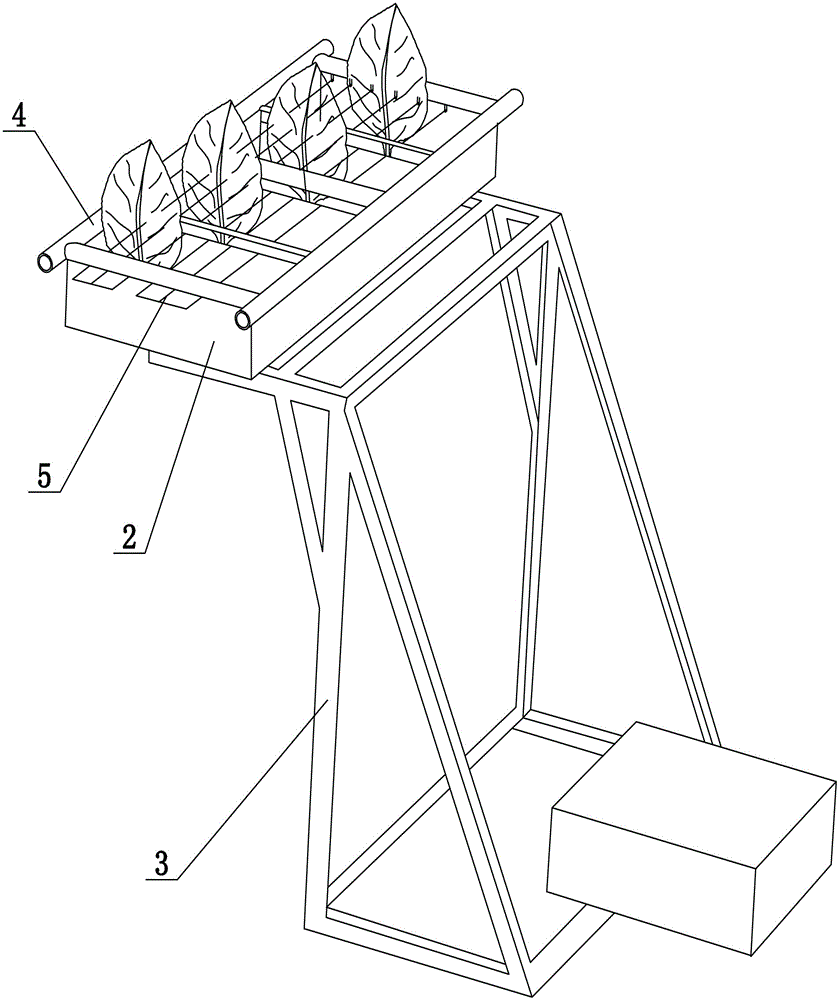

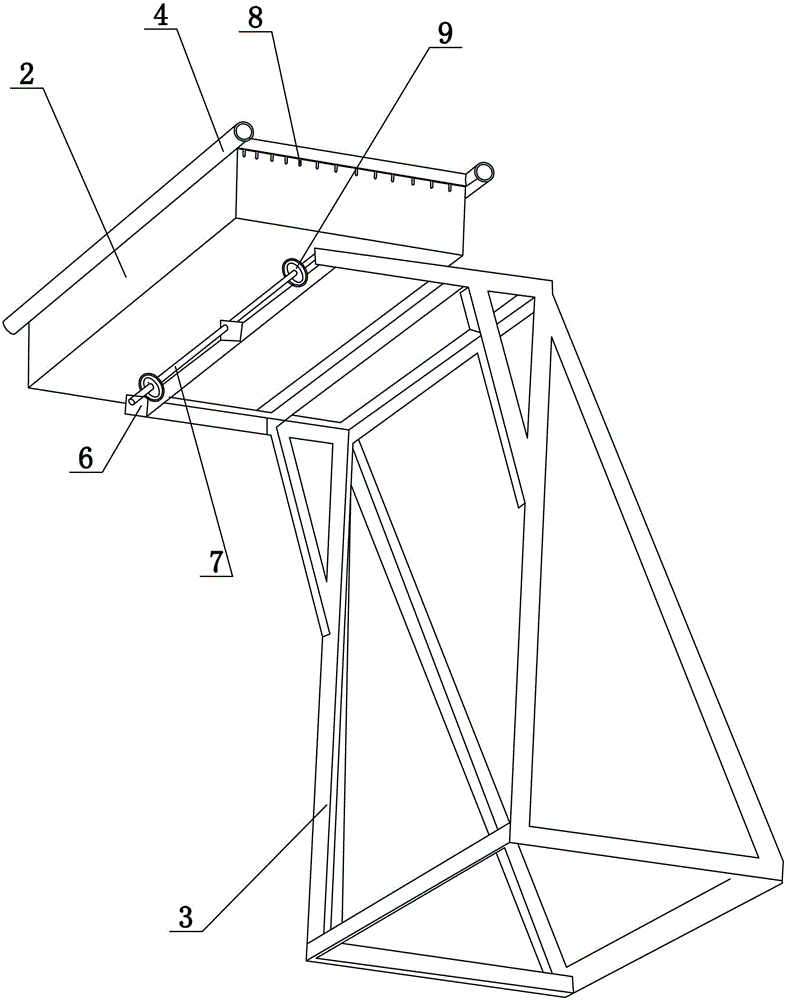

[0037] Such as figure 2 , image 3 As shown in the figure, a semi-automatic reversible cigarette loading operation table for dense barns, including a bracket 3, a grid plate 2, a load-bearing frame 4 and steel needles 5, the shape of the steel needles 5 is slender and is at least two steel needles 5 groups of steel needles composed of 5, the length of the steel needle 5 is greater than the length of the grid plate 2. At least three beams are arranged on the load-bearing frame 4 , and the length of the load-bearing frame 4 is greater than the length of the steel needle 5 . A connecting block 6 is arranged at the bottom of the grid plate 2, and the connecting block 6 and the bracket 3 are hinged through the hinge shaft 7, and the roller 9 is arranged on the hinge shaft 7, and the needle groove 8 is arranged on the grid plate 2, and the steel needle 5 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com