A tank-type thermal desorption device and desorption method based on thermal desorption additive filling

A technology of thermal desorption and thermal desorption unit, which is applied in the field of polluted soil treatment, can solve the problems of increasing the burden of exhaust gas treatment, residues, and reducing the removal rate of organic pollutants, and achieves improved thermal desorption efficiency, simple structure, and thermal desorption. With remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

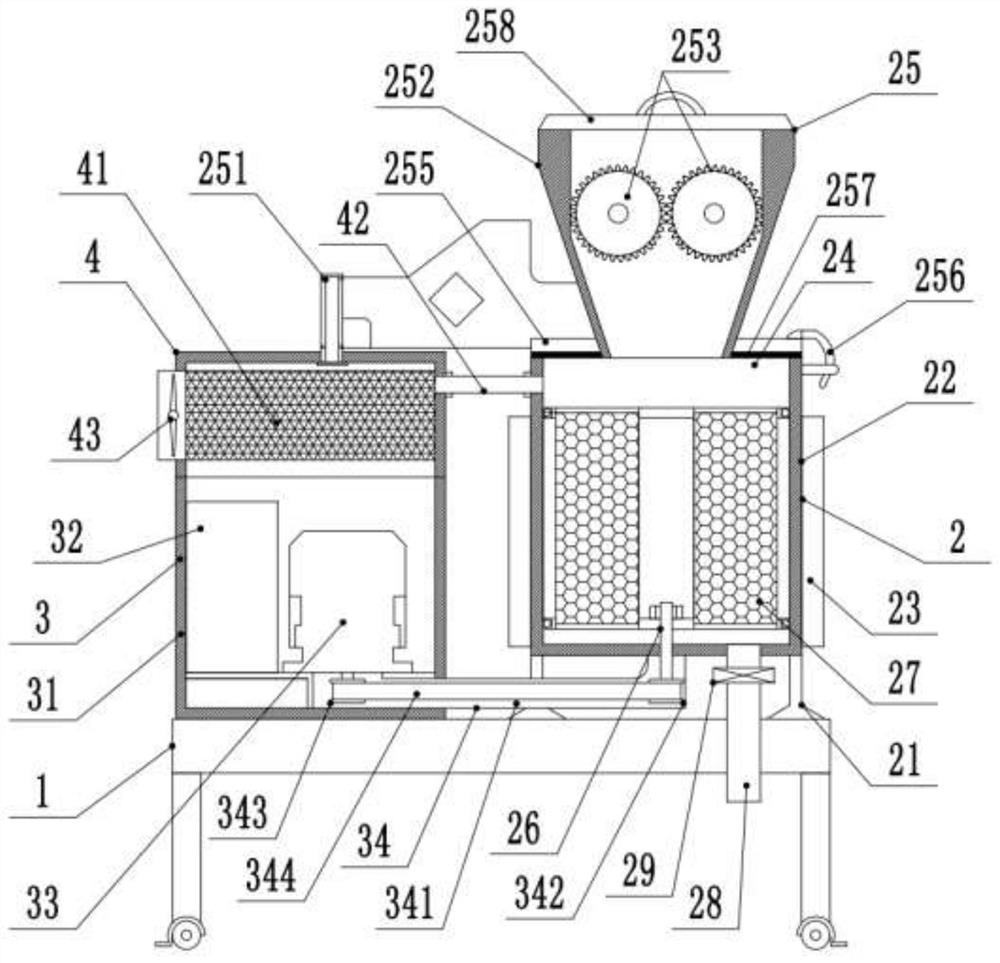

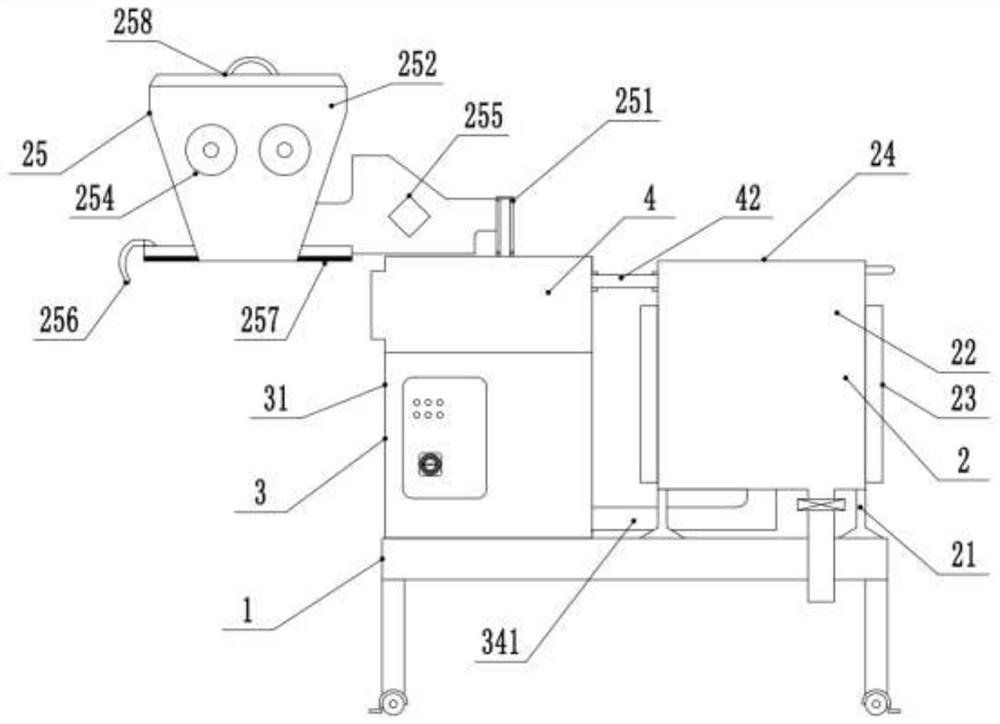

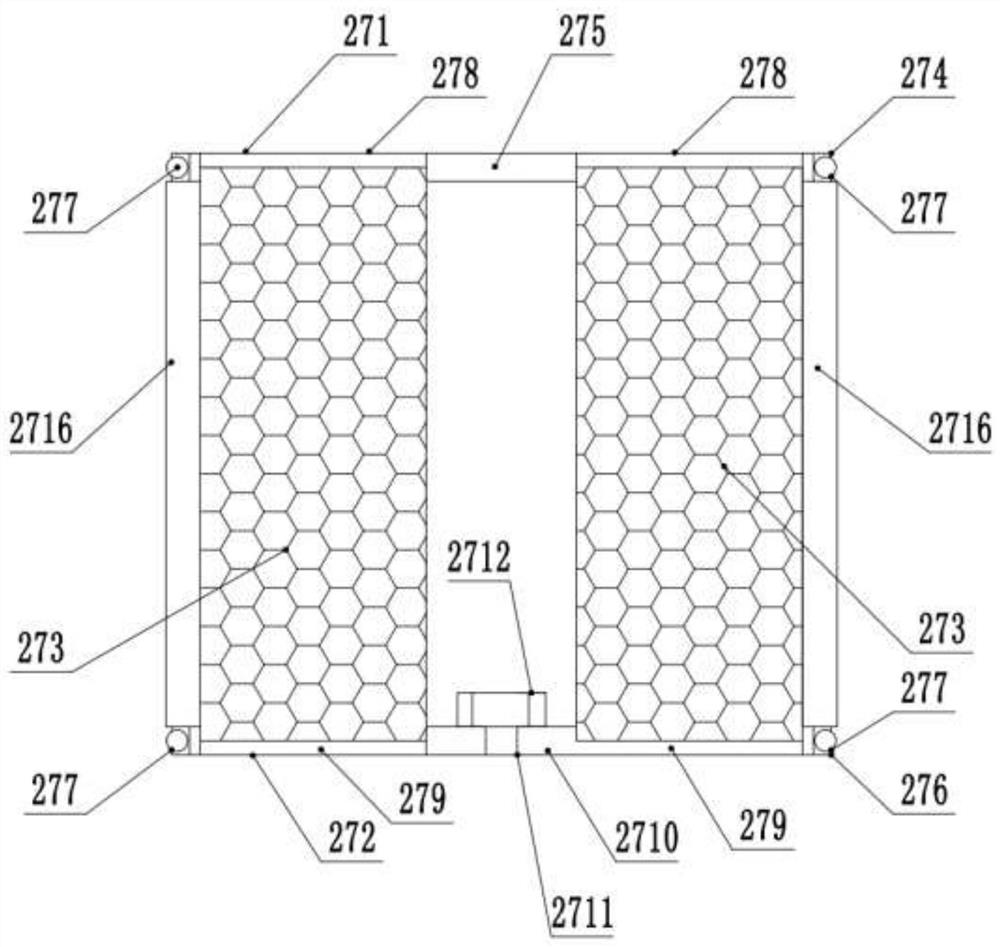

[0030] Such as figure 1 As shown, a tank-type thermal desorption device based on thermal desorption additive filling is characterized in that it includes a support frame 1, and a thermal desorption unit 2, a drive control unit 3, and an exhaust gas treatment unit located above the support frame 1 4; the thermal desorption unit 2 includes a thermal desorption tank 22 connected to the top of the support frame 1 by a support foot 21, and the thermal desorption tank 22 is provided with an electric heating jacket 23 for providing a heat source inside the thermal desorption tank 22, and the thermal desorption tank 22 The top of the desorption tank 22 is provided with a feed inlet 24, the top of the feed inlet 24 is connected with a soil pretreatment mechanism 25, and the center position of the bottom of the thermal desorption tank 22 is provided with a rotating shaft 26, and the upper end of the rotating shaft 26 is detachably connected with The rotary dial 27 filled with thermal de...

Embodiment 2

[0041] This example is basically the same as Example 1, except that the thermal desorption aid only has calcium peroxide particles as the A-type aid.

[0042] After thermal desorption, the removal rate of VOCs benzene was 81.2%, the removal rate of chlorinated organic compounds CVOCs was 79.1%, the removal rate of polycyclic aromatic hydrocarbons PAHs was 76.8%, and the removal rate of polychlorinated biphenyls PCBs was 77.4%.

Embodiment 3

[0044] This embodiment is basically the same as that of Embodiment 1, except that the thermal desorption auxiliary agent is only B-type auxiliary agent adsorbed with alumina balls of hydrogen peroxide solution.

[0045] After thermal desorption, the removal rate of VOCs benzene was 90.1%, the removal rate of chlorinated organic compounds CVOCs was 91.4%, the removal rate of polycyclic aromatic hydrocarbons PAHs was 89.7%, and the removal rate of polychlorinated biphenyls PCBs was 88.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com