Thermal desorption remediation device for polluted soil

A thermal desorption technology for contaminated soil, applied in the field of thermal desorption repair devices, can solve the problems of waste of heat energy, affecting the effect of thermal desorption, short contact time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

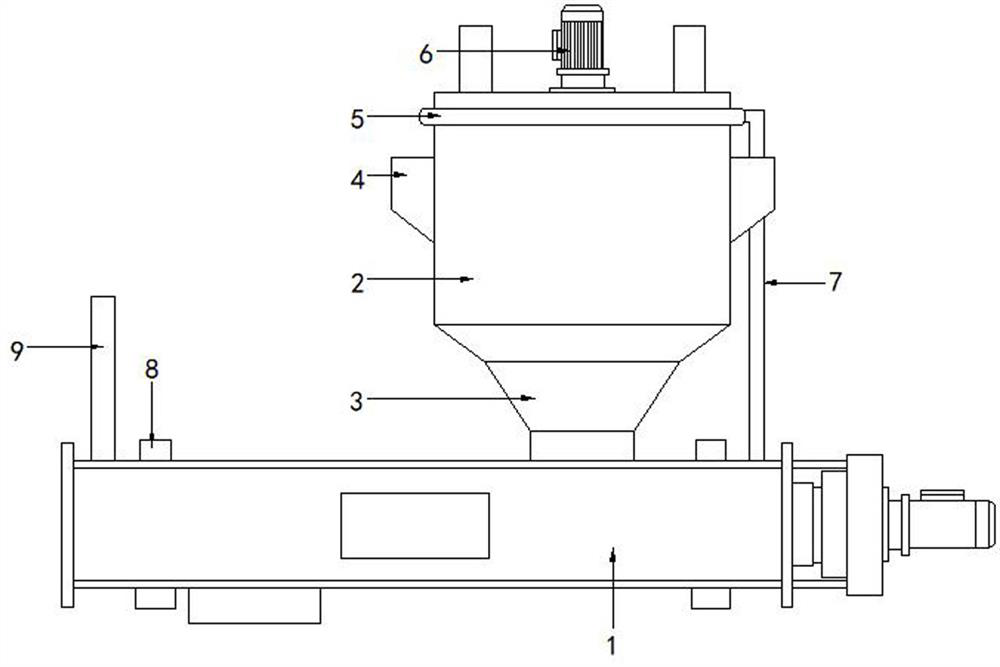

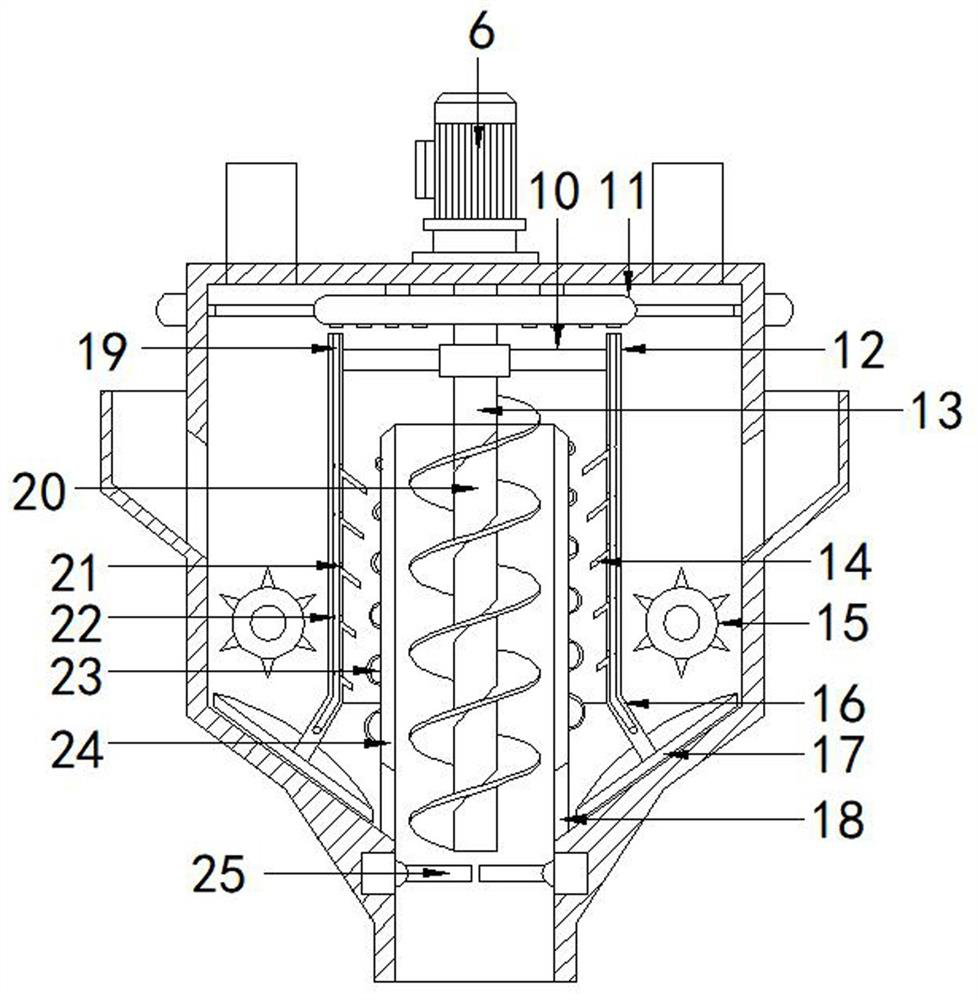

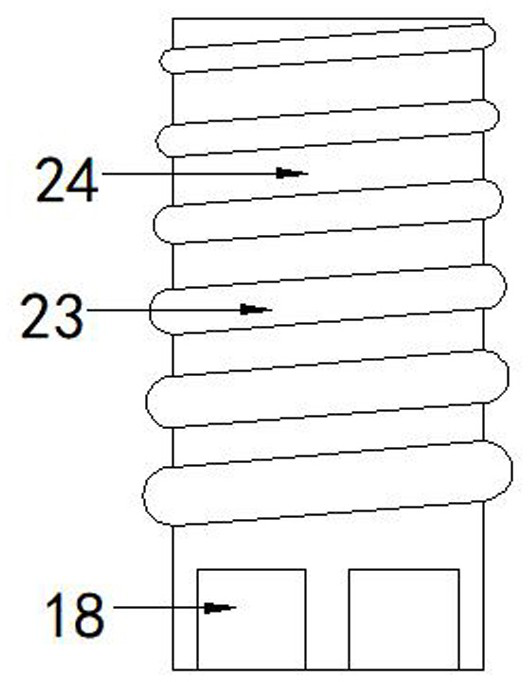

[0022] Such as figure 1 As shown, a thermal desorption restoration device for polluted soil includes a treatment device 2 connected in sequence from top to bottom and the internal cavity is communicated, a feed pipe 3 and a screw conveyor 1, and the screw conveyor The machine 1 and the feed pipe 3 are located on the top side of the screw conveyor 1; as figure 2 As shown, in the middle of the inner bottom of the processing device 2, a fixed pipe 24 with the same inner diameter as the feed pipe 3 is installed, and the lower end side wall of the fixed pipe 24 offers a feed guide hole 18, and the outer cover of the fixed pipe 24 A moving tube 12 is provided, and a transmission column 13 is also installed vertically inside the processing device 2. The end of the transmission column 13 extends into the fixed tube 24 and a spiral blade 20 is installed on the outer wall. The transmission column 13, the fixed tube 24 is coaxial with the moving tube 12, and the surface of the transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com