Roller-type reverse thermal desorption system for soil polluted by organic matters

A technology for thermal desorption of polluted soil, applied in the field of drum-type reverse thermal desorption system for organic polluted soil, which can solve the problems of dioxin generation, low thermal desorption efficiency, and inability to realize continuous feeding, and achieve large processing capacity , The effect of high thermal desorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

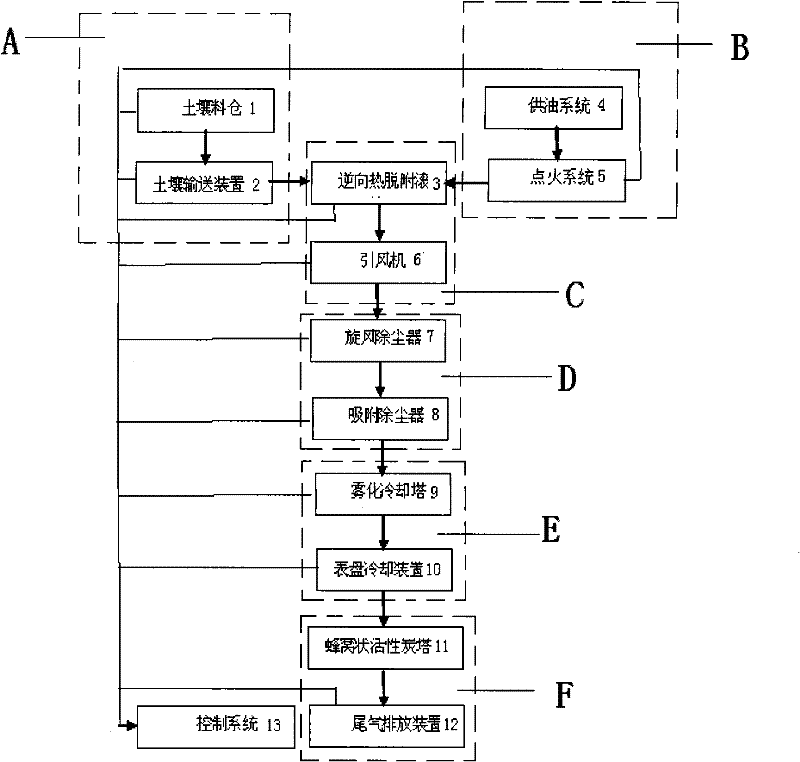

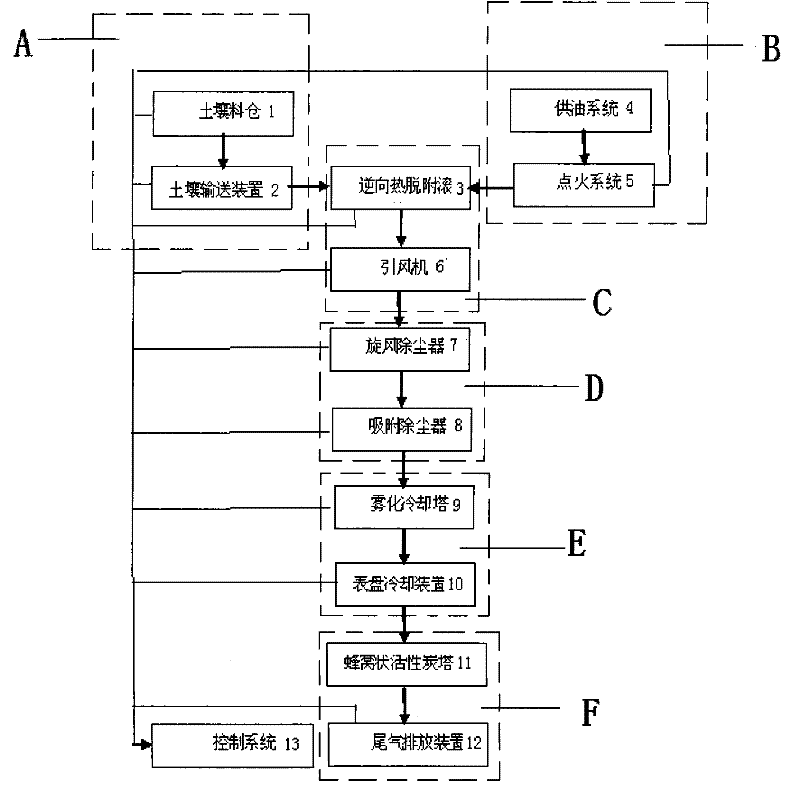

[0018] Referring to the accompanying drawings, a drum-type reverse thermal desorption system for organic matter polluted soil includes a soil feed system A, a heat source system B, a reverse thermal desorption system C, a dust removal system D, a cooling system E, an activated carbon adsorption system F and a control system 13. The output of the soil feeding system A is connected to the material input of the reverse thermal desorption system C, the output of the heat source system B is connected to the heat source input of the reverse thermal desorption system C, the output of the reverse thermal desorption system C is connected to the input of the dust removal system D, and the dust removal system The output of D is connected to the input of cooling system E, the output of cooling system E is connected to the input of activated carbon adsorption system F, soil feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com