Organic matter soil restoration device

A soil remediation and organic matter technology, which is applied in the restoration of polluted soil, soil material testing, material inspection products, etc., can solve the problems of secondary pollution, limited treatment capacity and high cost, and achieves large treatment capacity and thermal desorption efficiency. High, guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better realize the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

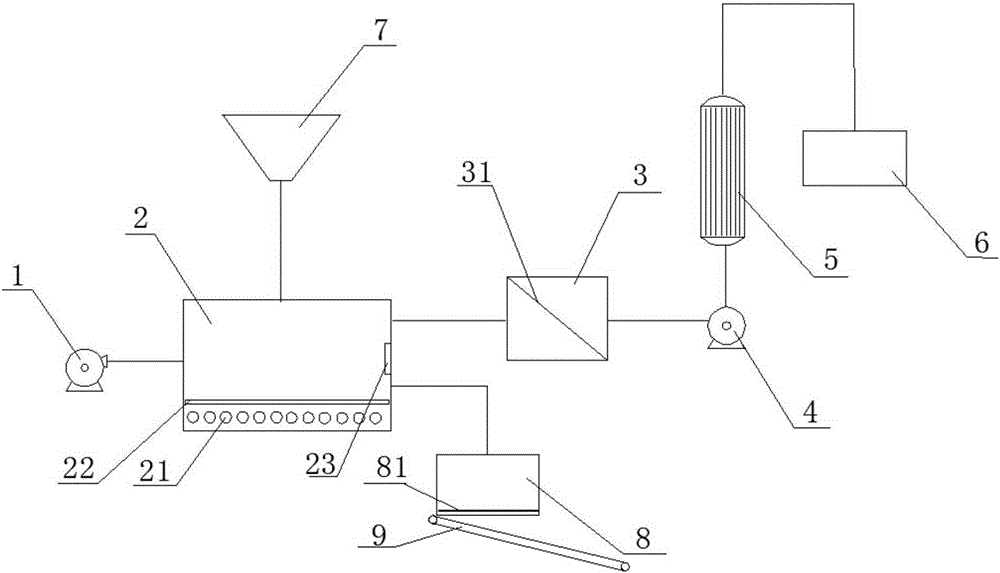

[0022] like figure 1 Shown, a kind of organic matter soil remediation device, comprises blower 1, soil remediation box 2, membrane separation system 3, vacuum pump 4, condenser 5, organic matter collection tank 6 connected successively by pipeline, described soil remediation box 2 tops are provided with Soil feeding port, the side of the soil remediation box 2 is provided with a soil discharging port, the soil feeding port is connected to the soil crushing box 7, the soil discharging port is connected to the soil cooling box 8, and the soil cooling box peripheral Discharging device 9 is arranged.

[0023] Preferably, the inner bottom of the soil remediation box 2 is provided with evenly distributed electric heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upstream pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com