A thermal desorption remediation device for pops pesticide-contaminated soil

A technology for thermal desorption of polluted soil, applied in the field of thermal desorption repair devices, can solve the problems of large investment in equipment, incomplete treatment of pollutants, high treatment costs, etc., achieve uniform heating, reasonable structural design, and improved thermal desorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

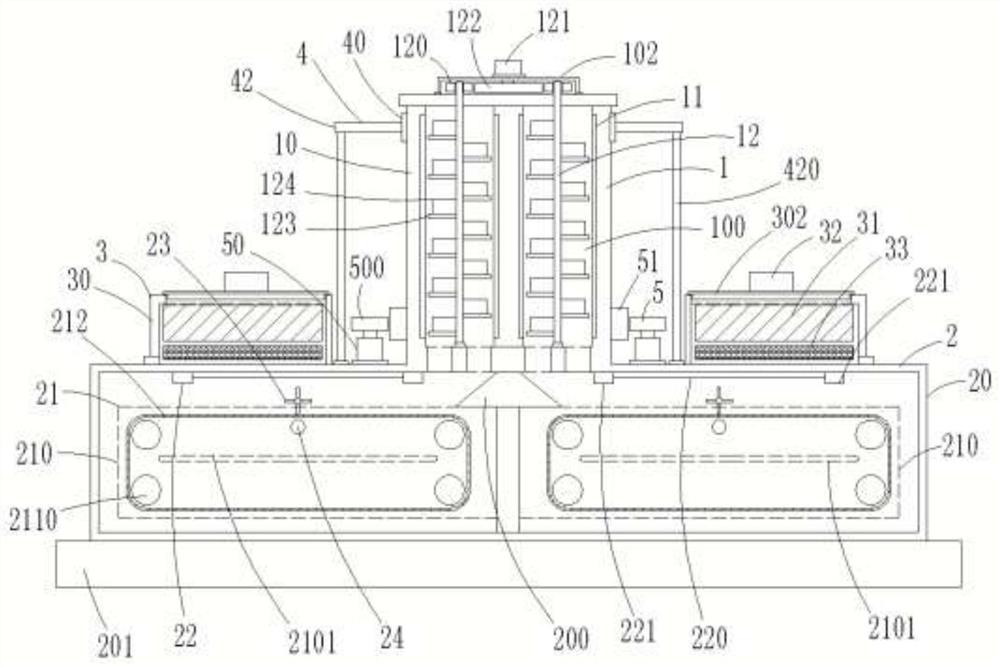

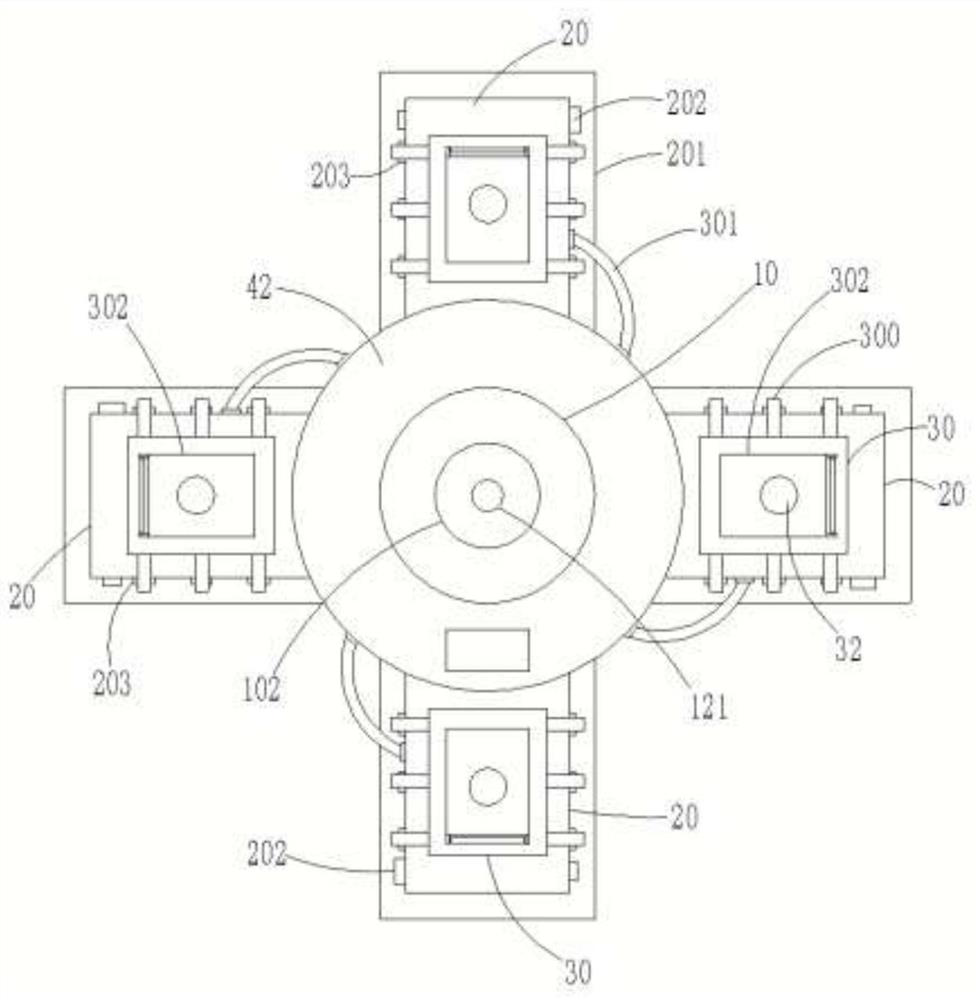

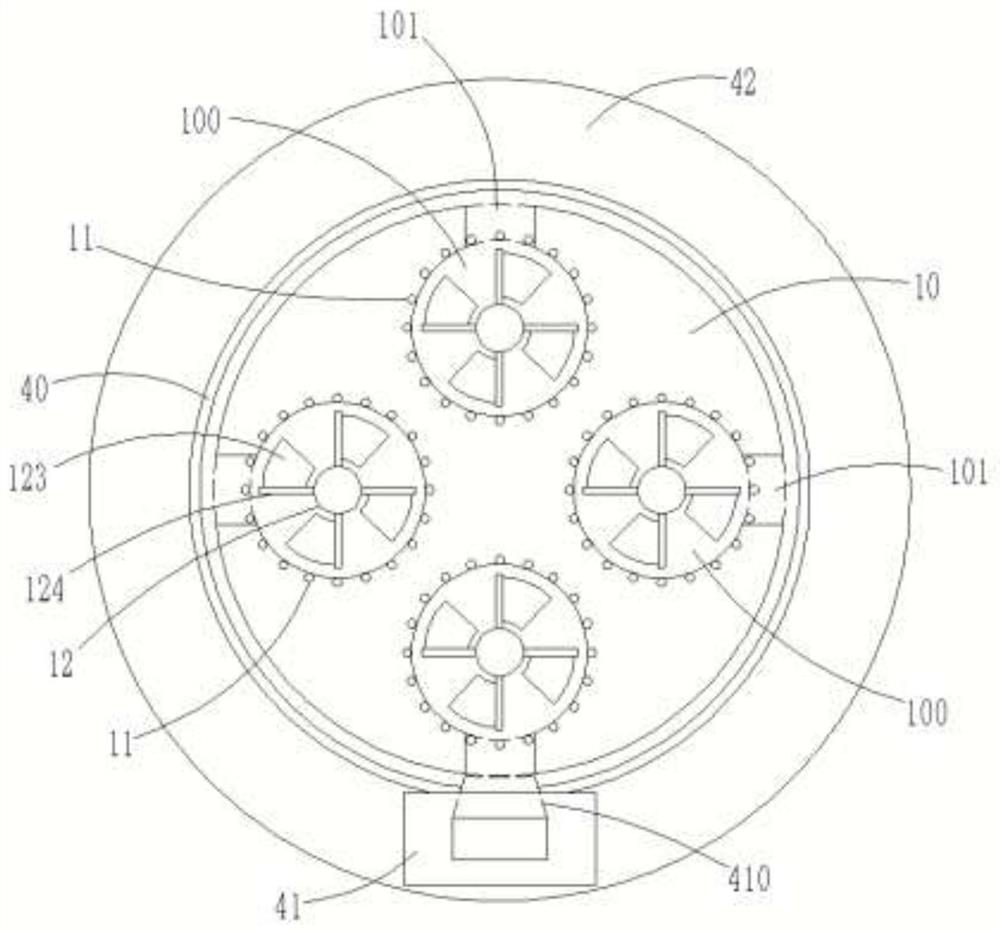

[0030] Example: such as figure 1 , 2 A thermal desorption remediation device for POPs pesticide-contaminated soil shown in . 5. The first-stage thermal desorption assembly 1 includes a pyrolysis cylinder 10, an electric heating rod 11 and a stirrer 12. The upper end of the pyrolysis cylinder 10 is sealed, and four pyrolysis chambers 100 are vertically distributed inside. The upper end of the side wall of the pyrolysis cylinder 10 is There are feeding holes 101 corresponding to the position and quantity of the pyrolysis chamber 100, the upper end of the pyrolysis cylinder 10 is provided with a device plate 102, and a plurality of electric heating rods 11 are provided, and the plurality of electric heating rods 11 are evenly distributed in each pyrolysis chamber The inner wall of 100 is circumferential, and the number of stirrers 12 corresponds to the pyrolysis chamber 100, and each stirrer 12 is respectively rotated and clamped inside each pyrolysis chamber 100, and the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com