A vertical soil thermal desorption device with internal and external heating and self-weight unloading

A technology of internal and external heating and soil heating, which is applied in the field of soil thermal desorption, can solve the problems of low heating rate and uneven heating, and achieve the effects of uniform heating, improved heat utilization rate, and increased heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

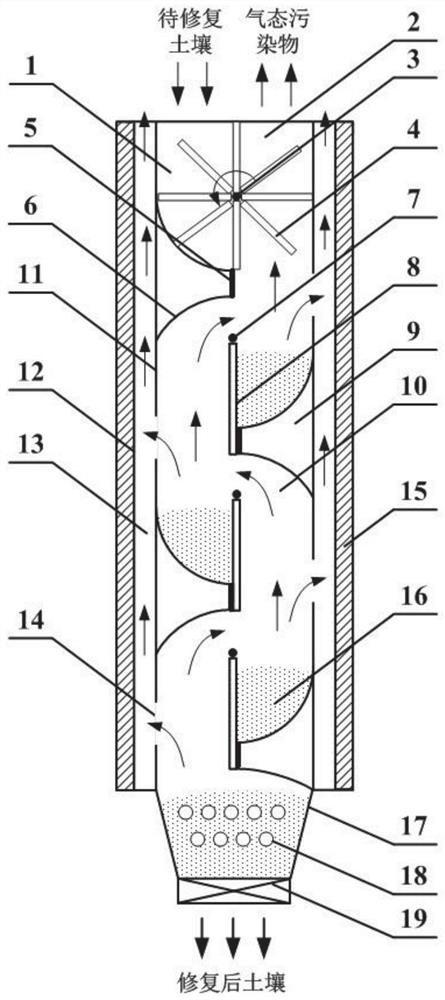

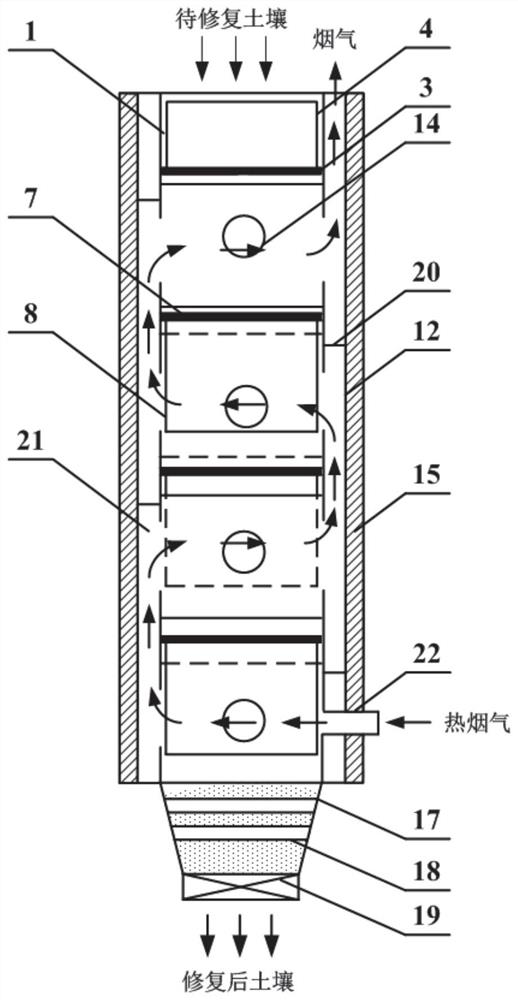

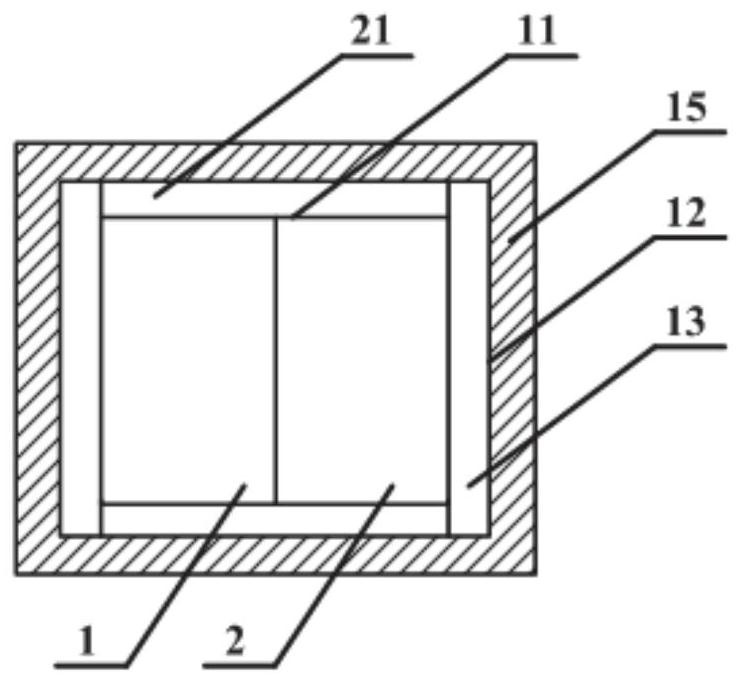

[0029] like figure 1 As shown in the figure, the vertical soil thermal desorption device for internal and external heating and self-weight unloading of this embodiment includes an inner channel 11, an outer channel 12 sleeved outside the inner channel 11, and a gap between the inner channel 11 and the outer channel 12. A plurality of thermal desorption units are arranged in the inner channel 11, and the structure of each thermal desorption unit includes a movable baffle 8 and a heating cavity 9, and the two ends of the heating cavity 9 are respectively There is a flue gas inlet and outlet communicating with the flue 21; each heating chamber 9 has at least one arc plate 6, and the arc plate 6 and the movable baffle 8 constitute a soil heating area, and the movable baffle 8 is under the action of soil gravity. Rotate around its top rotating shaft 7, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com