Method for defluorinating and preparing cryolite by secondary aluminum ash acid method

A secondary aluminum lime acid and cryolite technology, applied in the preparation/separation of ammonia, chemical instruments and methods, aluminate/alumina/aluminum hydroxide purification, etc., can solve the problem of unsatisfactory large-scale production and complicated process , Low product value and other issues, to achieve harmless and high-value utilization, avoid environmental pollution, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

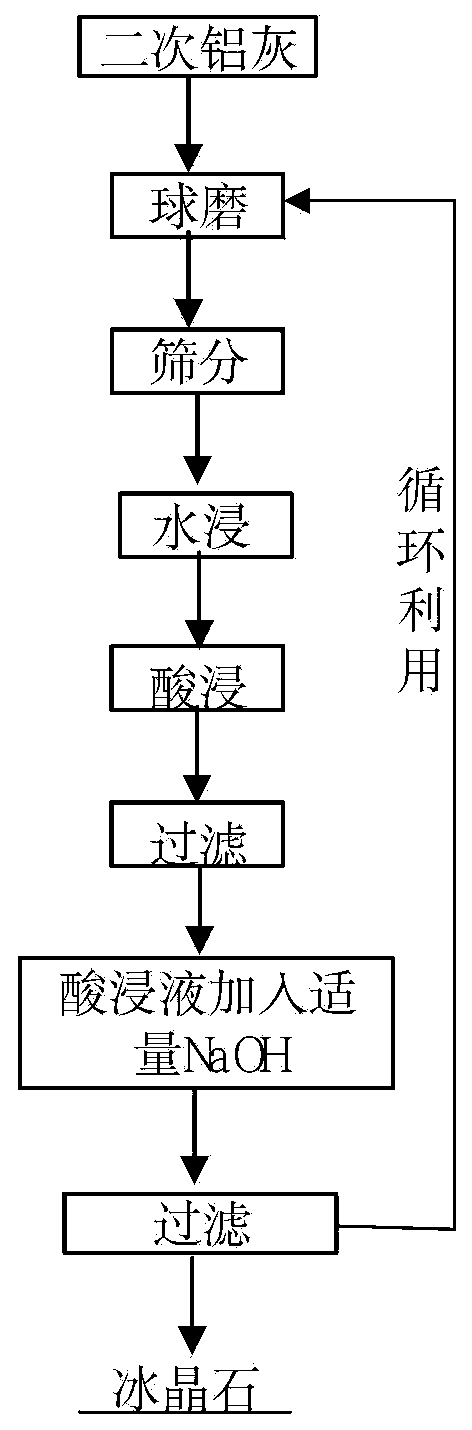

Method used

Image

Examples

Embodiment 1

[0033] The specific operation is as follows:

[0034] (1) Get 1kg secondary aluminum ash and sieve after ball milling, the yield on the sieve is 4.08%, the metal aluminum grade is 71.5%, and the recovery rate is 69.1%;

[0035] (2) Take 955g of secondary aluminum ash from which metal aluminum has been removed and add water to the reaction kettle at a liquid-solid ratio of 5:2, heat and stir at 100°C for leaching for 4 hours, and recover the overflowed ammonia gas with water to prepare ammonia water;

[0036] (3) After that, directly add an appropriate amount of concentrated hydrochloric acid to prepare 1mol / L hydrochloric acid, and carry out acid leaching and stirring leaching according to the liquid-solid ratio of 10:1, the leaching temperature is normal temperature, and the time is 1h;

[0037] (4) Carry out solid-liquid separation after acid leaching to obtain acid leaching slag and acid leaching liquid; the yield of acid leaching slag is 61%, which is alumina with a purity...

Embodiment 2

[0042] The specific operation is as follows:

[0043] (1) Get 1kg secondary aluminum ash and sieve after ball milling, the yield on the sieve is 3.53%, the metal aluminum grade is 79.86%, and the recovery rate is 66.23%;

[0044] (2) Take 960g of secondary aluminum ash from which metal aluminum has been removed and add water into the reaction kettle at a liquid-solid ratio of 5:2, heat and stir at 100°C for leaching for 6 hours, and recover the overflowing ammonia gas with water to prepare ammonia water;

[0045] (3) Afterwards, directly add an appropriate amount of concentrated hydrochloric acid to prepare 1.5mol / L hydrochloric acid, and carry out acid leaching and stirring leaching according to the liquid-solid ratio of 10:1, the leaching temperature is normal temperature, and the time is 1h;

[0046] (4) Carry out solid-liquid separation after acid leaching to obtain acid leaching slag and acid leaching liquid; the yield of acid leaching slag is 55.1%, which is alumina with...

Embodiment 3

[0051] The specific operation is as follows:

[0052] (1) Get 1kg secondary aluminum ashes and sieve after ball milling, the yield on the sieve is 4.4%, the metal aluminum grade is 68.2%, and the recovery rate is 70.1%;

[0053] (2) Take 950 g of secondary aluminum ash from which metal aluminum has been removed and add water to the reaction kettle at a liquid-solid ratio of 5:2, heat and stir at 100° C. for leaching for 4 hours, and recover the overflowed ammonia gas with water to prepare ammonia water;

[0054] (3) After that, directly add an appropriate amount of concentrated hydrochloric acid to equip it with 3mol / L hydrochloric acid, and carry out acid leaching and stirring leaching according to the liquid-solid ratio of 5:1, the leaching temperature is normal temperature, and the time is 1h;

[0055] (4) Carry out solid-liquid separation after acid leaching to obtain acid leaching slag and acid leaching solution; the yield of acid leaching slag is 54.4%, which is alumina ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com