A device and method for treating oily sewage

A treatment device and technology for oily sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve high cost of anode loss, high power consumption, consumption Major problems, to achieve the effect of reducing sludge production, low device operating costs, and saving chemical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

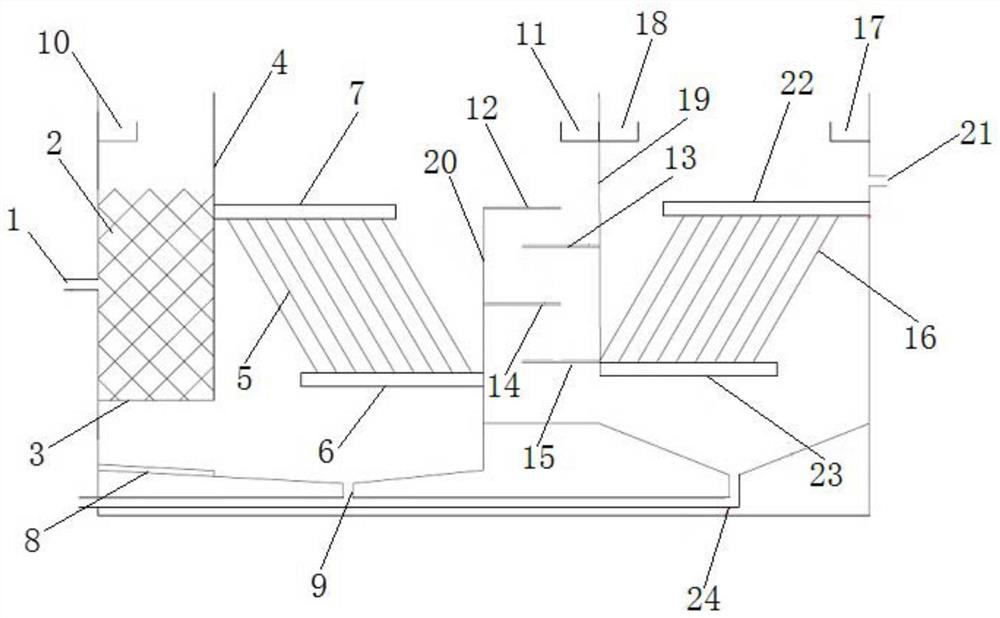

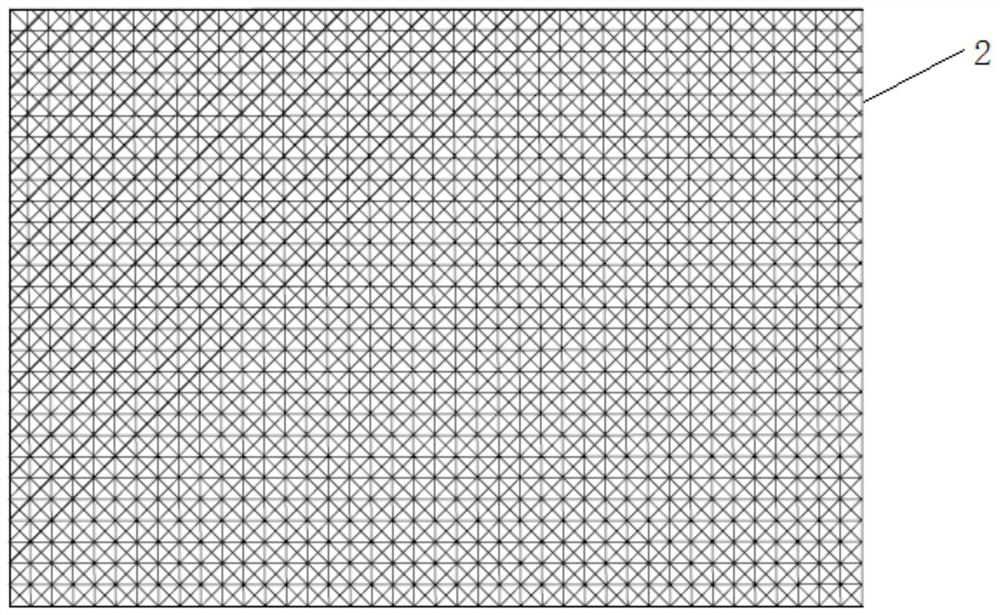

[0049] Such as figure 1 with figure 2 As shown, the present invention provides an oily sewage treatment device, which includes: a water inlet 1, a water outlet 21, an oil stain removal unit and a suspended solids removal unit; wherein, the oil stain removal unit includes an oil stain coalescing unit and an oil stain ramp Plate sedimentation unit, a first baffle 4 is arranged between the oil stain coalescing unit and the oil stain sloping plate sedimentation unit; both the oil stain coalescing unit and the oil stain sloping plate sedimentation unit are charged units; the suspended matter removal The part includes an electroflocculation unit, a suspended matter inclined plate settling unit and a sludge sedimentation concentration unit, and a second baffle 19 is arranged between the electroflocculation unit and the suspended matter inclined plate settlement unit, and the sludge sedimentation concentration unit It is arranged at the lower part of the suspended matter sloping pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com