Catalytic oxidation purification device and method for high-chlorine degradation-resistant wastewater

A technology of catalytic oxidation and purification device, which is applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc. The effect of avoiding problems, reducing the production of iron sludge, stable and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

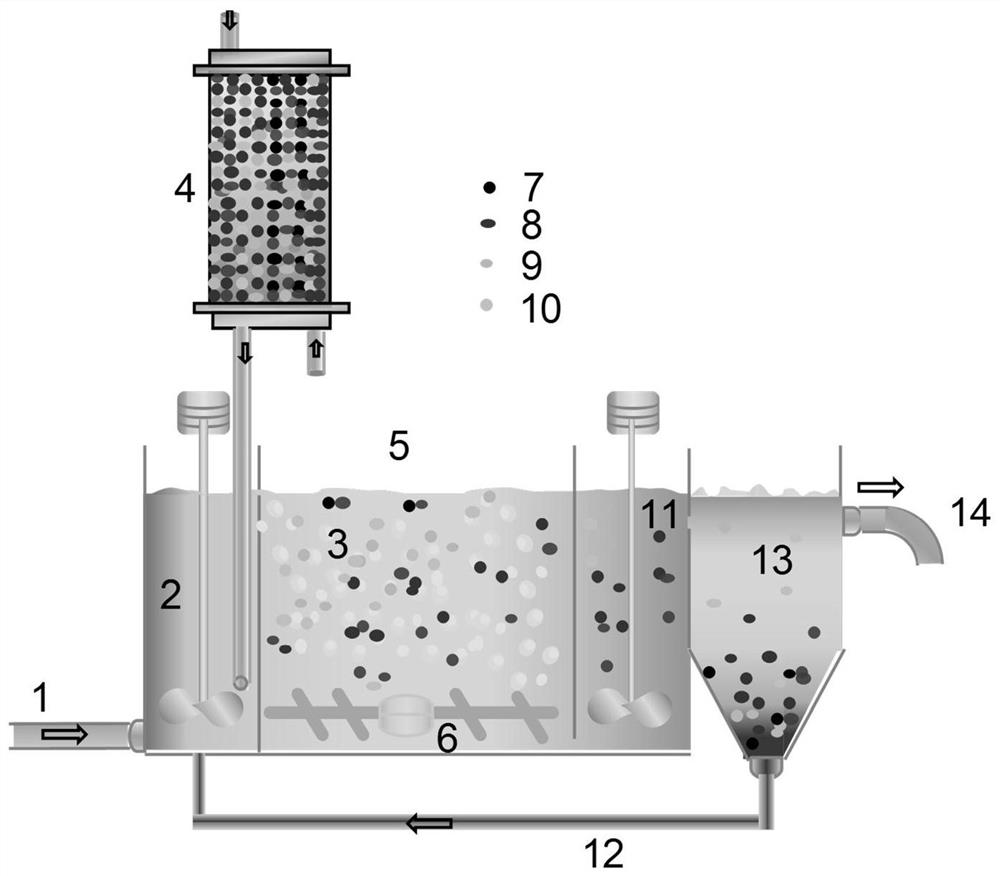

[0052] In the preparation process of the catalyst, the particle size of the catalyst is set between 120-800 mesh. On the one hand, the catalytic activity must be considered, and on the other hand, the stability of the catalyst must be considered.

[0053] Depending on the water quality and the amount of hydrogen peroxide added, the consumption of the catalyst will also be different. According to the difference in the consumption of the catalyst, it is necessary to replenish the catalyst in real time to keep it at a stable reaction level.

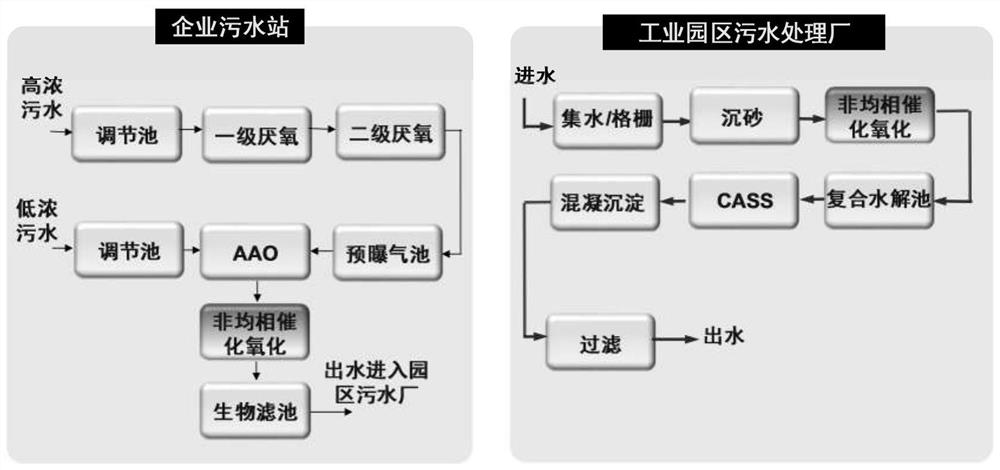

[0054] (2) Properly add hydrogen peroxide in the main reaction zone to make the catalyst react well with hydrogen peroxide to produce a sufficient amount of hydroxyl radicals, and simultaneously according to the follow-up treatment ( figure 2 ) section and effluent water quality to adjust the addition of hydrogen peroxide, control the TOC removal rate below 50% when the reactor is connected to the biochemical treatment section, and control t...

Embodiment 1

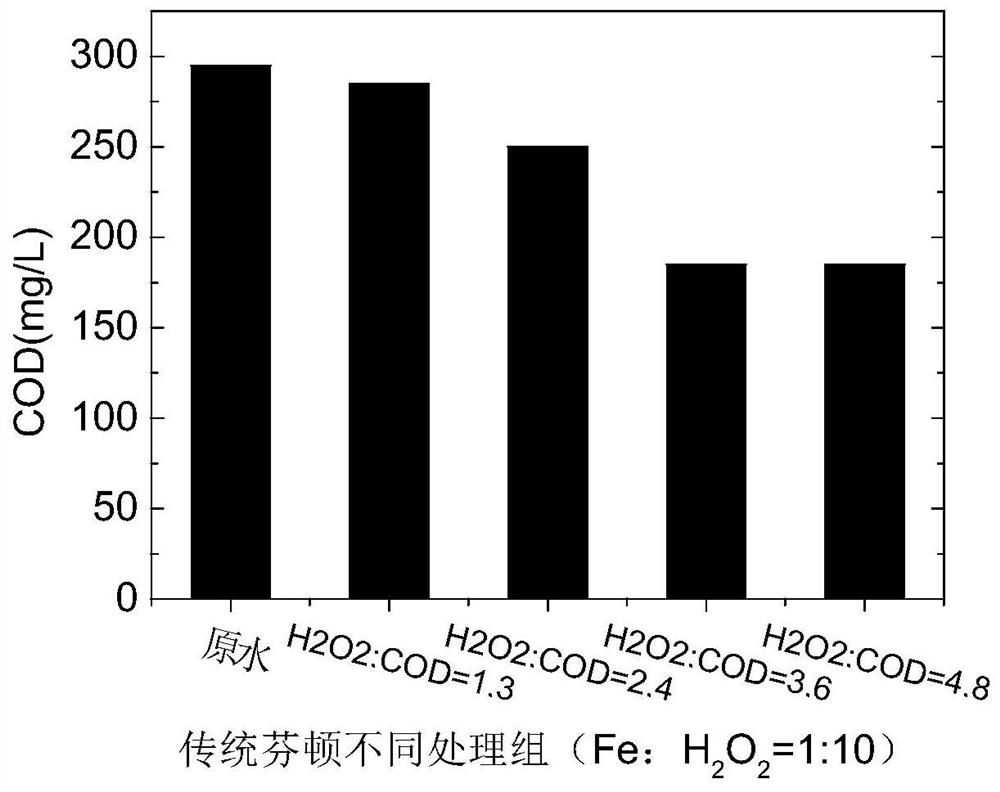

[0061] The influent of a sewage treatment plant in an industrial park in Hunan is mainly composed of pyridine and chlorinated pyridine compounds, the influent chloride ion is 3000-5000mg / L, the COD is between 200-300mg / L, and the influent TOC is between 100-170mg / L , the influent ammonia nitrogen is 20mg / L, and the total nitrogen is about 25mg / L. The Fenton-hydrolytic acidification-oxidation ditch coupling process was used for treatment. During the treatment process, due to the interference of chloride ions on the Fenton process, the Fenton effluent before and after COD, TOC, etc. have basically no obvious changes, and increasing the dosage of hydrogen peroxide still cannot achieve a good removal of COD ( image 3 ), because chloropyridines cannot be removed by Fenton technology, and chloropyridines have a strong inhibitory effect on nitrifying bacteria, resulting in the obstruction of the ammonia oxidation process in the biochemical section and the limitation of the denitrific...

Embodiment 2

[0065] The influent of a sewage treatment station of a pesticide enterprise in Jiangsu is high-chlorine refractory wastewater, and the influent contains chlorinated organics such as dimethomorph, imidacloprid, thiazolone, pyridines, and thiazoles, and the influent COD8000-15000mg / L, chloride ions 4000-6000mg / L, the sewage treatment station mainly adopts Fenton pretreatment-anaerobic-aerobic process for treatment. Due to the interference of chloride ions, the effect of Fenton treatment is not obvious, and at the same time, the output of iron sludge is large, and the cost of disposal as hazardous waste is high. In order to temporarily ensure the normal progress of part of the production process, some chlorinated organic compounds and pyridine organic compounds are processed through incineration, which is too costly and the production capacity of enterprises is limited by the treatment of high-salt and refractory wastewater.

[0066] After adopting the catalytic oxidation technol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com