Landfill leachate treatment device based on anaerobic ammonium oxidation and its application method

A landfill leachate and anaerobic ammonium oxidation technology, applied in the field of landfill leachate treatment devices, can solve the problems of high operating pressure, high operating load of the membrane system, and increased failure rate of the membrane system, achieving low water treatment costs and saving Aeration energy consumption, the effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

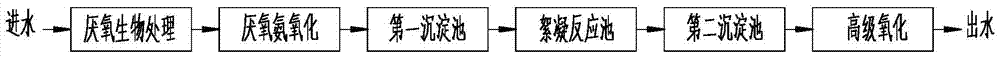

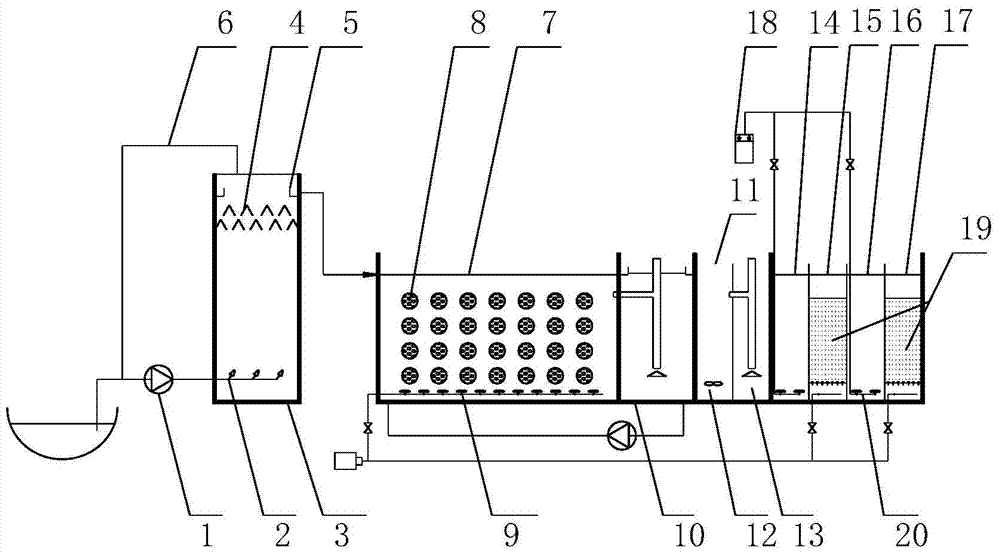

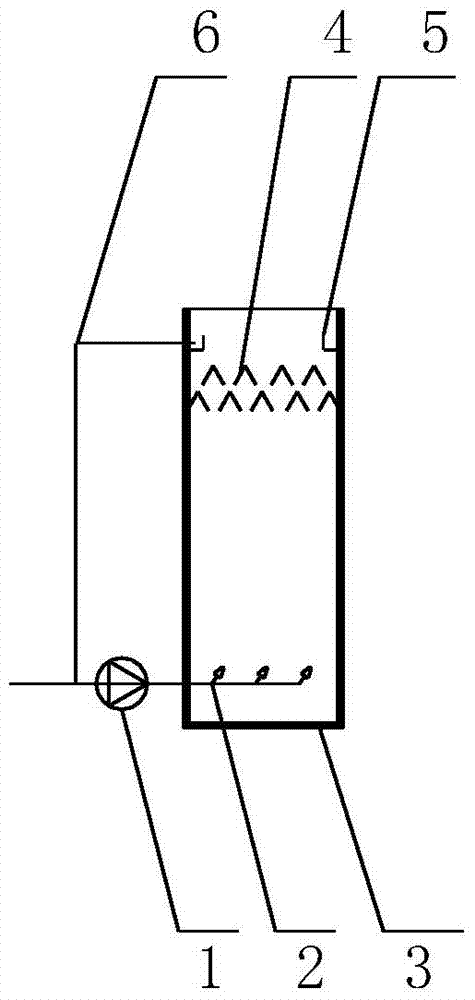

[0027] Attached below Figure 1-5 The landfill leachate treatment device based on anaerobic ammonium oxidation and its use method of the present invention are described in detail.

[0028]A landfill leachate treatment device based on anaerobic ammonium oxidation, the treatment device includes a first-level treatment unit, a second-level treatment unit, and a third-level treatment unit connected in sequence through a pipeline system; the first-level treatment unit is anaerobic Biological treatment unit, the second-level treatment unit is anaerobic ammonium oxidation treatment unit, the third-level treatment unit is flocculation sedimentation and advanced oxidation treatment unit; among them, the first-level treatment unit includes water inlet pump 1, water distribution system 2, first Reactor 3, three-phase separator 4, water outlet weir trough 5, water outlet return pipe 6, water inlet pump 1 is connected with water distribution system 2, water distribution system 2 is set at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com