Vibrating flat plate ceramic membrane bioreactor technology for enhancing phosphorus removal, and sewage treatment system

A technology of membrane bioreactor and ceramic membrane, which is applied in biological water/sewage treatment, water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the problem of not being able to meet the municipal sewage phosphorus discharge standard and having no phosphorus pollutant treatment procedures , can not effectively alleviate membrane fouling and other problems, and achieve the effect of excellent thermal stability and pore stability, small footprint, and not easy to clog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

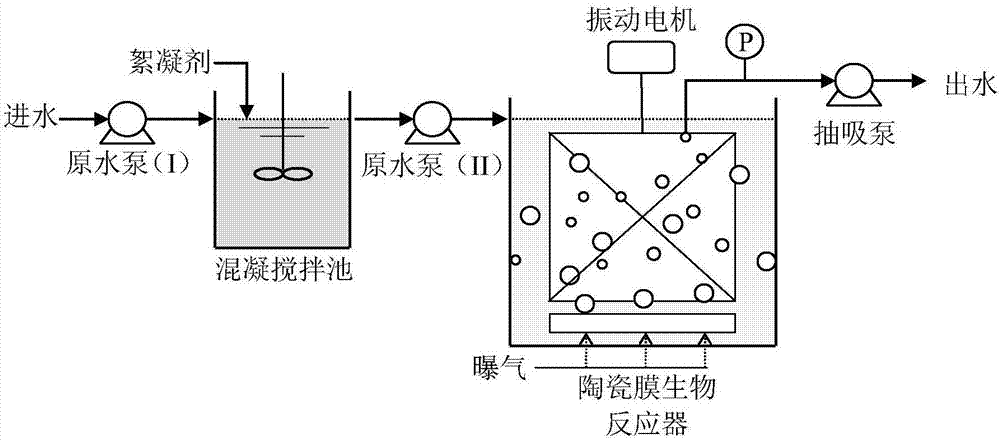

[0034] A sewage treatment system for a vibration plate ceramic membrane bioreactor process that strengthens phosphorus removal, including: a coagulation tank, a membrane bioreactor and a vibration device,

[0035] Among them, there is a fast agitator in the coagulation tank;

[0036] The coagulation tank and the membrane bioreactor are connected through the pumping pipeline and the raw water pump. There is an aeration head at the bottom of the aerobic reactor, which is connected to the external air flow meter and air pump in turn through the air pipeline;

[0037] The flat ceramic membrane is fixed on one end of the metal frame and submerged vertically in the aerobic reactor, and is connected with the suction pressure gauge and suction pump outside the reactor in turn through the suction pipeline, and the vibration motor is fixed on the other end of the metal frame and is located in the aerobic reactor. above the device.

[0038] Unless otherwise specified, after the various...

Embodiment 2

[0040] A kind of vibrating plate ceramic membrane bioreactor process that adopts the sewage treatment system described in embodiment 1 to strengthen dephosphorization, comprises:

[0041] (1) Sewage continuously enters the coagulation mixing tank through the raw water pump (I) to mix with the flocculant, and the hydraulic retention time of the coagulation mixing tank is 1 to 2 minutes. The flocculant preferably chooses iron salt, aluminum salt and other compounds that are easy to precipitate with phosphate. Through rapid stirring (preferably rotating speed>200RPM), the pollutants in the sewage and the flocculant produce flocs. Among them, orthophosphate and flocculant form coprecipitate, which changes from dissolved state to precipitated state.

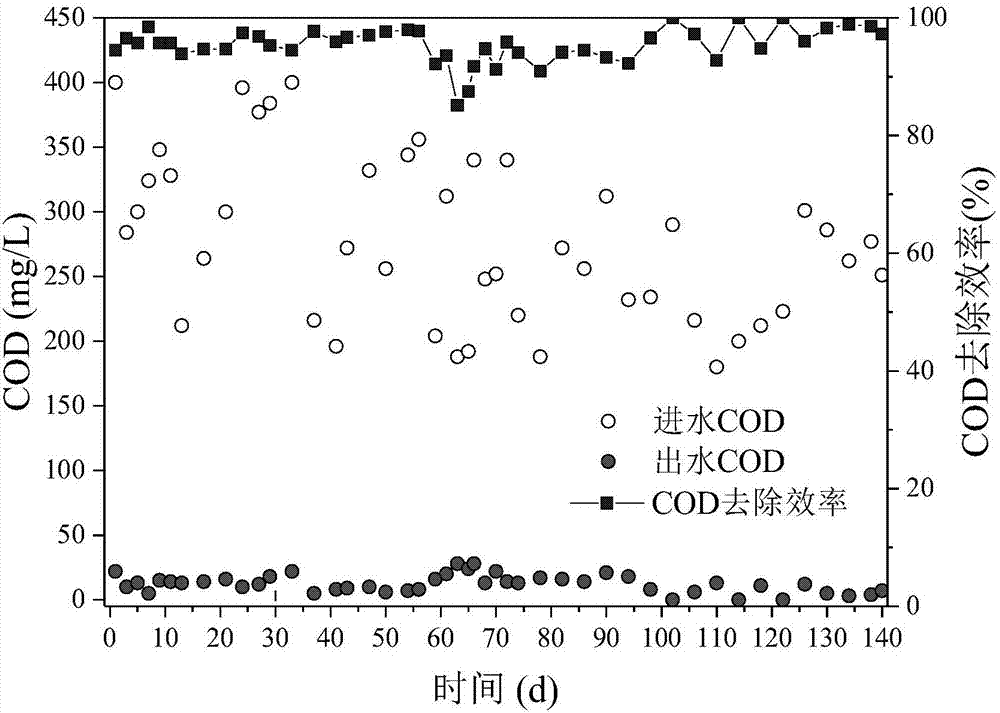

[0042] (2) The mixed solution enters the aerobic membrane bioreactor through the raw water pump. The reactor is inoculated with activated sludge and supplied with oxygen through an air pump. A flat ceramic membrane is submerged in ...

Embodiment 3

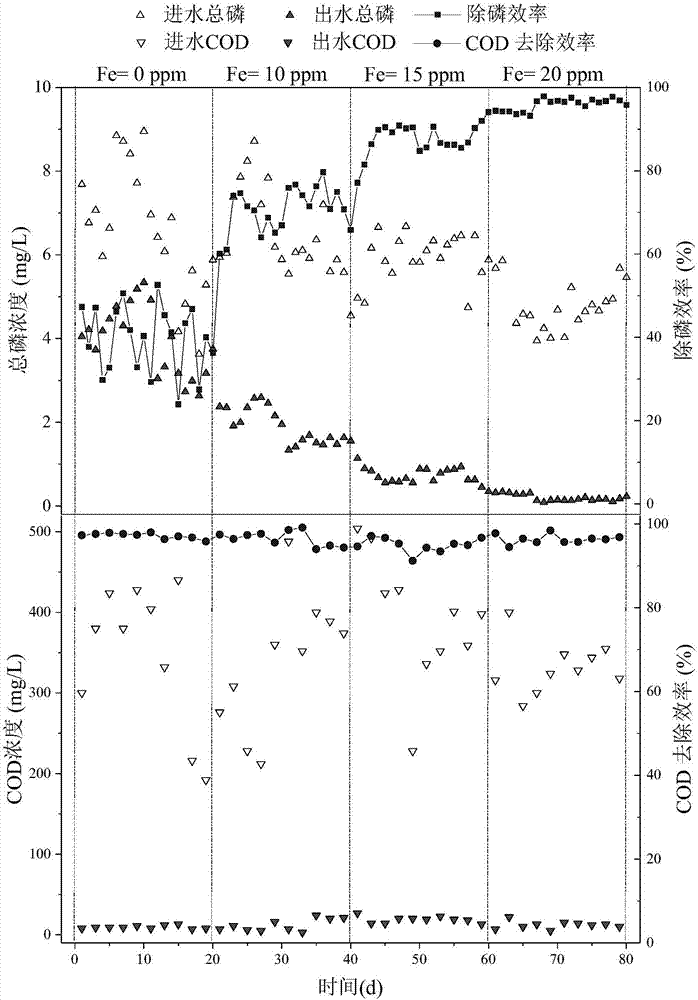

[0044] Embodiment 3: compare the removal efficiency of pollutants under different doses of coagulants

[0045] Adopt the scheme of embodiment 2, coagulant uses ferric chloride, dosage increases from small to large, is respectively 0,10,15,20mg-Fe / L. Each dosage condition was run for 20 days to ensure that the reactor reached a steady state. Firstly, the raw water pump (I) pumps the municipal sewage into the coagulation tank and mixes it with the coagulant ferric chloride. The average organic matter concentration of sewage is 360mg-COD / L, and the average total phosphorus concentration is 6.35mg / L. The stirring speed in the coagulation tank is 200rpm, and the hydraulic retention time is 2min. At the same time, the raw water pump (II) pumps the mixed solution from the coagulation tank into the membrane bioreactor (8L) at a flow rate of 16L / d. Activated sludge (4.12g / L) was inoculated in the membrane bioreactor, the hydraulic retention time was 12h, and the sludge retention tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com