Hydrazine hydrate wastewater treatment device and technology thereof

A wastewater treatment and treatment process technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of expanding enterprise production capacity, improving market competitiveness, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

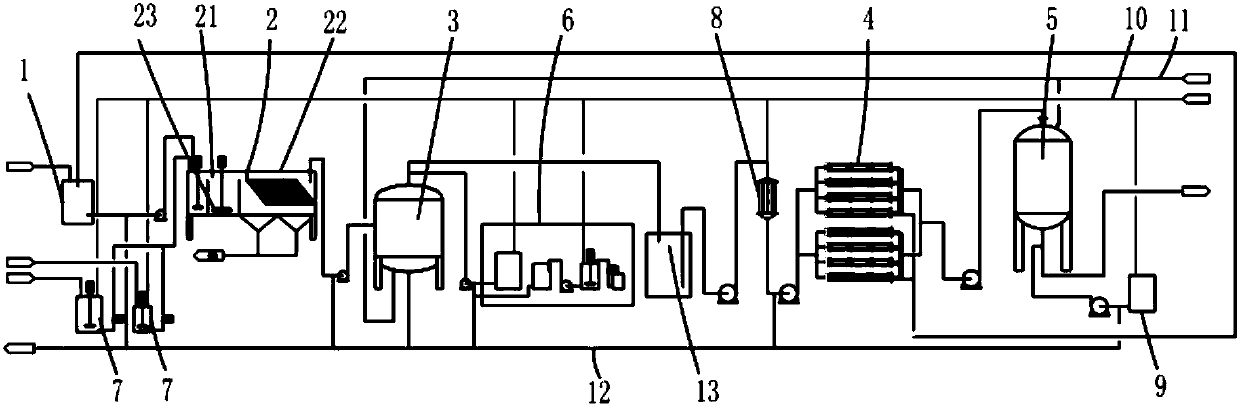

[0039] like figure 1 Shown, a kind of hydrazine hydrate waste water treatment device comprises raw water tank 1, flocculation sedimentation tank 2, ceramic membrane filter 3, nanofiltration filter 4 and activated carbon filter 5 connected successively, and flocculation sedimentation tank 2 comprises flocculation tank 21 and The sedimentation tank 22, the flocculation tank 21 is provided with a stirring device 23, the flocculation sedimentation tank 2 is connected with the flocculant storage tank 7, the flocculant storage tank 7 is used to add flocculant to the flocculation tank 21, the concentrated water pipe of the nanofiltration filter 4 The outlet is connected to the inlet of the raw water tank 1, the concentrated water is circulated through repeated circulation without discharge, the ceramic membrane filter 3 is connected to the ceramic membrane washing and alkali cleaning equipment 6, the activated carbon filter 5 is connected to the cleaning tank 9, and the ceramic membra...

Embodiment 2

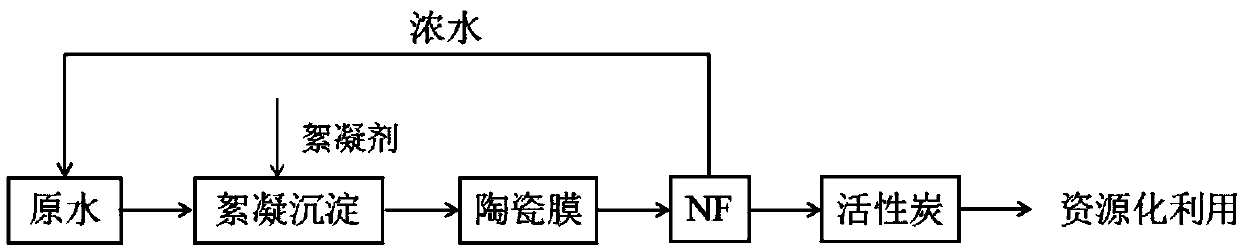

[0041] like figure 2 Shown, a kind of treatment process of hydrazine hydrate waste water treatment plant comprises the steps:

[0042] (1) Put the sewage in the raw water tank into the flocculation tank with stirring device, and add the flocculant PAC into the flocculation tank from the flocculant storage tank at the same time, the addition amount is 50000mg / L, and then pour it into the sedimentation tank, the sewage Suspended impurities and colloids are aggregated into large particles in the sedimentation tank and settled under the action of gravity for biochemical treatment;

[0043] (2) the sewage after the flocculation and sedimentation in the described step (1) is squeezed into the ceramic membrane filter, the aperture of the ceramic membrane filter element is 2 μm, and the membrane flux of the ceramic membrane filter element is 200L (m 2 h) -1 , the operating pressure is 0.08MPa, intercepting unsettled small molecular suspended matter, colloid and other particles in t...

Embodiment 3

[0048] like figure 2 Shown, a kind of treatment process of hydrazine hydrate waste water treatment plant comprises the steps:

[0049] (1) Pour the sewage in the raw water tank into the flocculation tank with a stirring device, and at the same time add the flocculant PAM into the flocculation tank from the flocculant storage tank, the addition amount is 100mg / L, and then pour it into the sedimentation tank, and the sewage Suspended impurities and colloids are aggregated into large particles in the sedimentation tank and settled under the action of gravity for biochemical treatment;

[0050] (2) the sewage after the flocculation and sedimentation in the described step (1) is squeezed into the ceramic membrane filter, the aperture of the ceramic membrane filter element is 7 μ m, and the membrane flux of the ceramic membrane filter element is 600L (m 2 h) -1 , the operating pressure is 0.1MPa, intercepting unsettled small molecular suspended matter, colloid and other particles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com