Method for preparing coal tar or coaltar pitch without quinoline insolubles

A technology of coal tar and coal tar pitch, which is applied in the field of preparing coal tar or coal pitch that does not contain quinoline insolubles, can solve problems such as difficult operation, increased volatility of organic matter, and recovery rate when consuming energy, and achieve simple process , Mild conditions, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

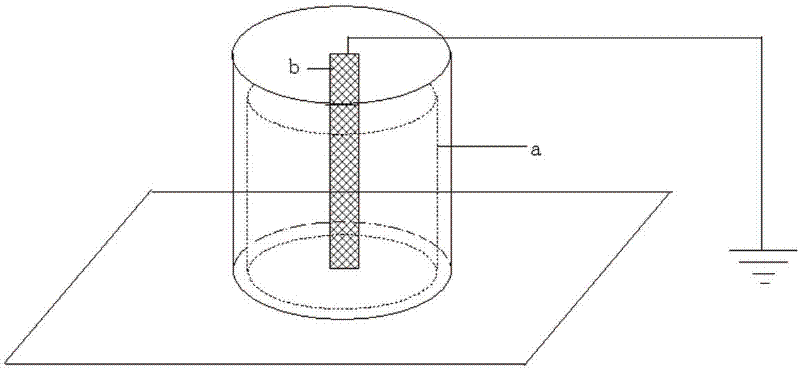

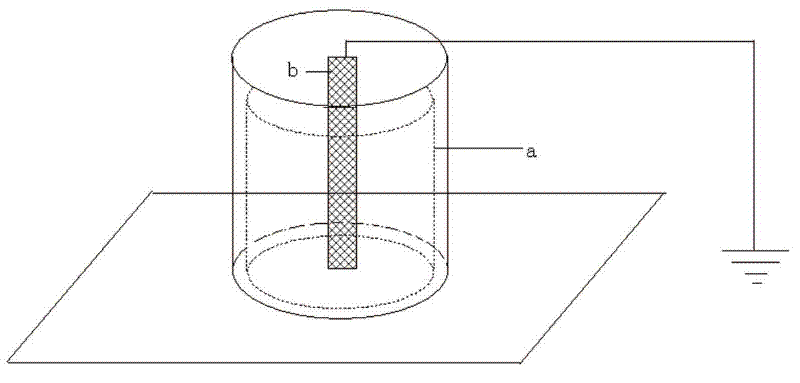

[0014] Take 50g of high-temperature coal tar (the content of QI is 3.6 wt%) and put it in a 300ml glass beaker, add a solvent capable of dissolving high-temperature coal tar and 25mg of lauryltrimethylammonium chloride, and in general, dissolve 50g of high-temperature coal Tar can be dissolved by adding a solvent of equal volume ratio. The solvent can be one of light oil, phenol oil, naphthalene oil, washing oil, benzene and toluene, or a mixture of several. In the present embodiment, select 50ml of toluene, put in such as figure 1 In the shown beaker, the electrode made of conductive metal material or non-metallic material with a certain shape is connected with the power supply. In this embodiment, the electrode made of stainless steel is connected with the power supply. The power supply adopts a common power supply. Heat the coal tar to 50°C in a water bath, then turn on the power, and adjust the electric field strength to 7.5×10 4 V / m, stop heating after 1 hour of continuo...

Embodiment 2

[0016] Same as Example 1, get 50g of medium temperature coal tar pitch (the content of QI is 5.3 wt%) and place in a 300ml glass beaker, add 50ml of washing oil and 100mg of lauryltrimethylammonium chloride and put it into such as figure 1 In the container shown, connect the electrode made of stainless steel with the power supply, heat it to 80°C with an electric heating mantle, turn on the power supply, and adjust the electric field strength to 2.0×10 5 V / m, stop heating after 40 minutes of continuous action time, turn off the power switch, take out the electrode, transfer the coal tar pitch containing the solvent to the distillation device, and distill off the solvent at a temperature of 210°C under reduced pressure to obtain the treated For coal tar pitch, the method described in the national standard GB / T-2293-1997 was used to measure the content of quinoline insolubles. As a result, no QI was detected, that is, the QI content was lower than the detection limit of the assay...

Embodiment 3

[0018] With embodiment 1, get 50g middle temperature coal tar (the content of QI is 5.3wt%) and be placed in the glass beaker of 300ml, after adding the lauryl trimethyl ammonium chloride of 60ml benzene and 250mg, put into such as figure 1 In the container shown, connect the electrode made of copper material to the power supply, adjust the temperature to 10°C with an ice-water bath, turn on the power supply, and adjust the electric field strength to 3.0×10 5 V / m, stop heating after 1 hour of continuous action time, turn off the power switch, take out the electrode, transfer the coal tar containing solvent to a distillation device, and distill off the solvent at a temperature of 50°C under reduced pressure to obtain the treated Coal tar adopts the method described in the national standard GB / T-2293-1997 to measure quinoline insoluble content, and the existence of QI is not detected equally, that is, the QI content of the above-mentioned processed coal tar is lower than the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com