Copper-cerium double-metal modified 4A molecular sieve desulfurization adsorbent as well as preparation method and application thereof

A molecular sieve, bimetallic technology, applied in chemical instruments and methods, refined hydrocarbon oil, other chemical processes, etc., can solve the problems of harsh reaction conditions, inability to efficiently remove thiophene, etc., to solve the steric hindrance effect and excellent adsorption. Effect of desulfurization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

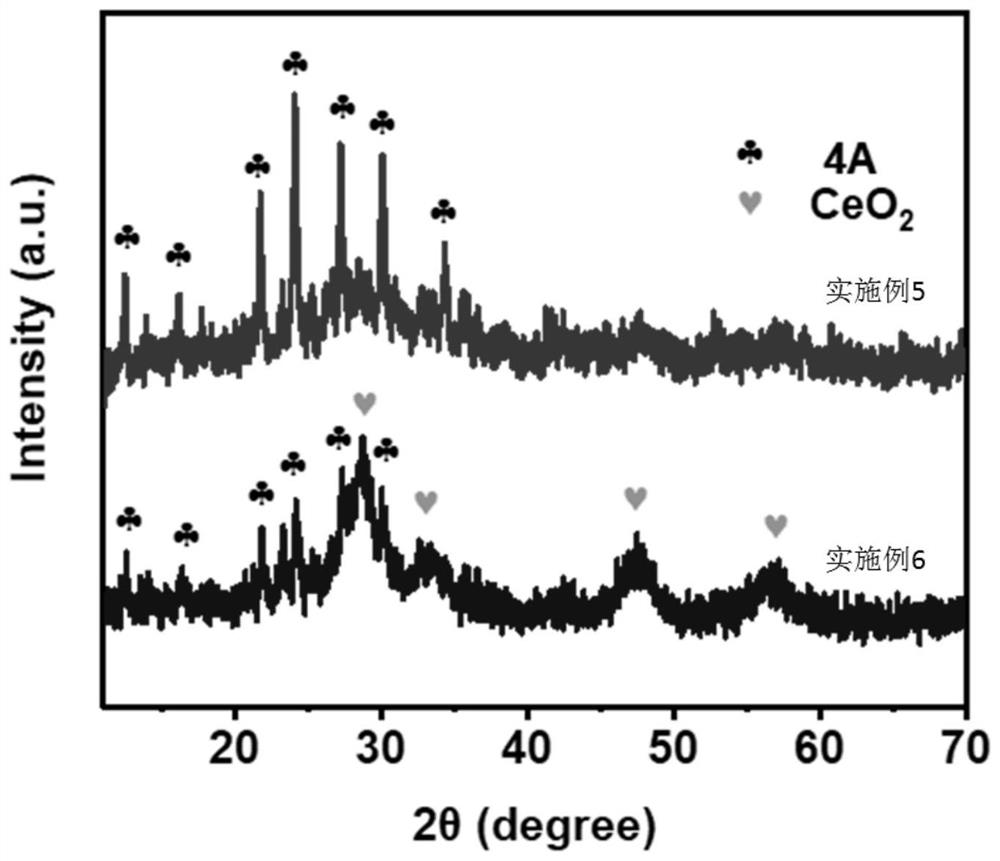

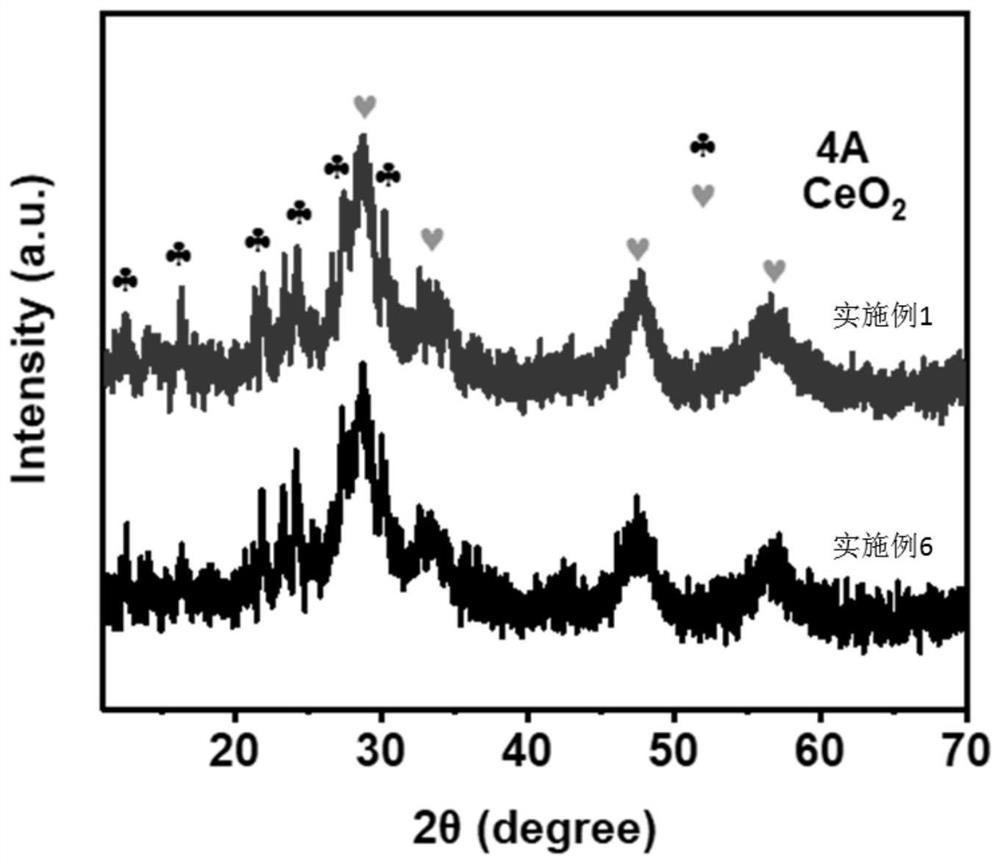

Embodiment 1

[0034] The 4A molecular sieve was synthesized from kaolin as a carrier, and the copper precursor solution and the cerium precursor solution were used to modify the 4A molecular sieve twice, and the active components copper and cerium were successfully loaded on the molecular sieve to realize the deep adsorption desulfurization of DBT.

[0035] Preparation of copper-cerium bimetallic modified 4A molecular sieve adsorbent: Weigh 5g of 4A molecular sieve, place it in 50ml of 0.5M cuproammonia solution, perform ion exchange at 50°C for 12 hours under reflux conditions, collect samples by centrifugation after the exchange, and place in Drying at 100°C for 12 hours, followed by calcination at 550°C, the calcination process is: heating up to 550°C at 5°C / min, holding for 4 hours and then cooling in the furnace, the monometallic copper modified adsorbent can be prepared, denoted as CuA. Preparation of bimetallic modified 4A molecular sieve adsorbent: Weigh 2g of CuA molecular sieve, pl...

Embodiment 2

[0038] The 4A molecular sieve was synthesized from kaolin as a carrier, and the copper precursor solution and the cerium precursor solution were used to modify the 4A molecular sieve twice, and the adsorbent was used for the adsorption of DBT.

[0039] Copper modification process is identical with embodiment 1, just this moment copper source changes copper nitrate into;

[0040] The experimental process of DBT adsorption desulfurization is the same as that in Example 1.

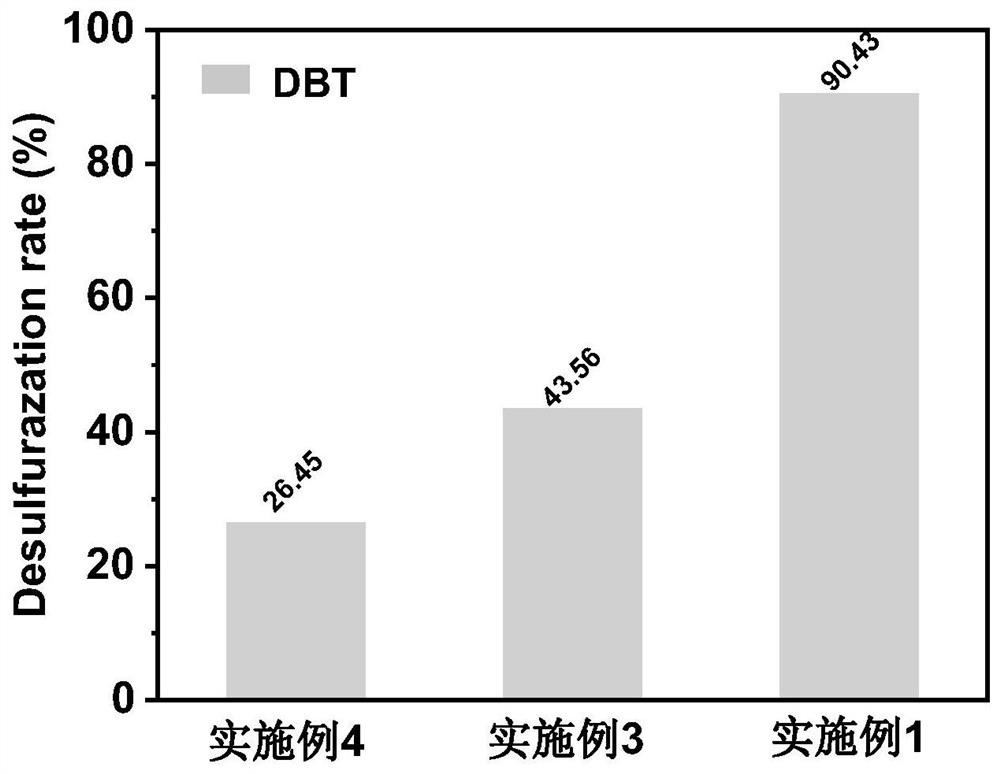

Embodiment 3

[0042] The 4A molecular sieve was synthesized from kaolin as a carrier, and the copper precursor solution and the cerium precursor solution were used to modify the 4A molecular sieve twice, and the adsorbent was used for the adsorption of DBT.

[0043] The copper modification process is the same as in Example 1, except that the cuproammonia solution concentration is changed to 0.3M at this time;

[0044] The experimental process of DBT adsorption desulfurization is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com