Cooling box for CTOD (crank tip opening displacement) test and operating process of cooling box

A cooling box and testing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve problems such as falling off, finger intrusion, operator injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

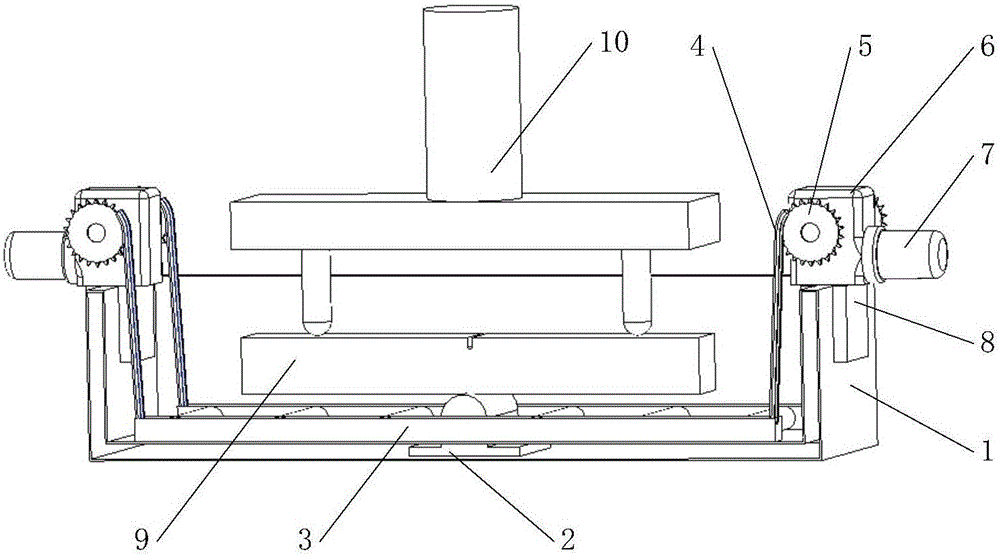

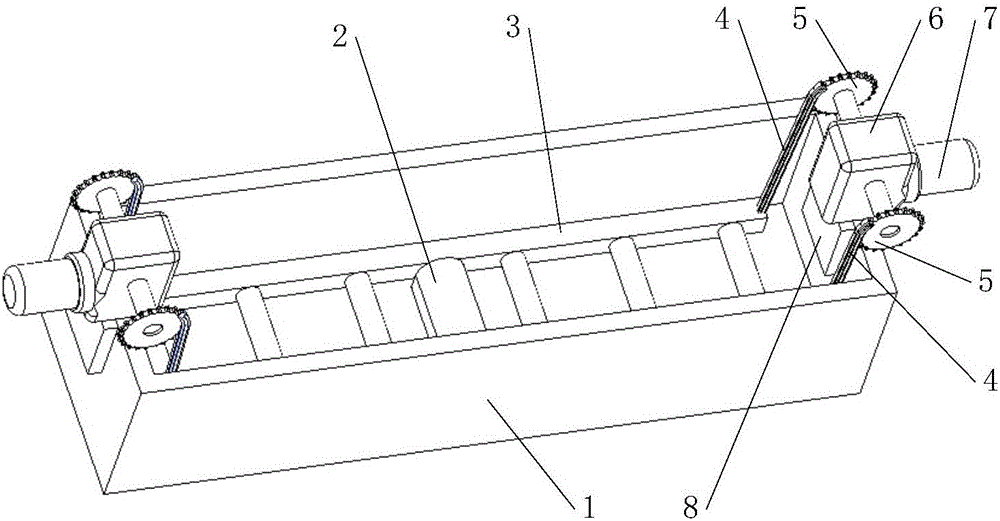

[0025] see figure 1 and 2 , shows the cooling box for CTOD test of the present invention and its operation process, which is used to test the open displacement test of the crack tip of the welded joint, so that the test piece can be safely and smoothly placed in place during the test, and the test piece can be lifted out Coolant, and remove.

[0026] The cooling box for the CTOD test includes a box body 1, a top head 2, a lifting frame 3 and a lifting mechanism. The box body 1 is rectangular, and its upper end is opened for putting in a test piece. The top head 2 is arranged at the bottom of the box body 1. The middle position, the lifting frame 3 is movably placed in the box body 1, the lifting mechanism is two sets and is respectively located on the two side walls of the box body 1, each lifting mechanism is connected to the two sides of the lifting frame 3 to Provide the lifting frame 3 to move up and down in the box body 1.

[0027] Wherein, the lifting mechanism such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com