Method for preparing specimens used in testing of mechanical properties of thin-walled and small-diameter petroleum and natural gas pipelines

A technology for oil and gas sample preparation, which is applied in the field of preparation of oil and gas thin-walled small-diameter pipeline mechanical performance samples, which can solve the problems that it is difficult to meet the sample size requirements such as tensile, impact, fracture toughness, and crack growth rate. , to achieve the effect of saving materials and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with specific embodiments.

[0054] This embodiment detects the in-service natural gas pipeline of PetroChina Changqing Oilfield Gas Production No. 1 Plant: the material is 20# steel, and the pipeline size is φ114mm×6mm. Tensile, impact, CTOD fracture toughness and crack growth rate tests are required. The specific implementation steps of sample preparation include:

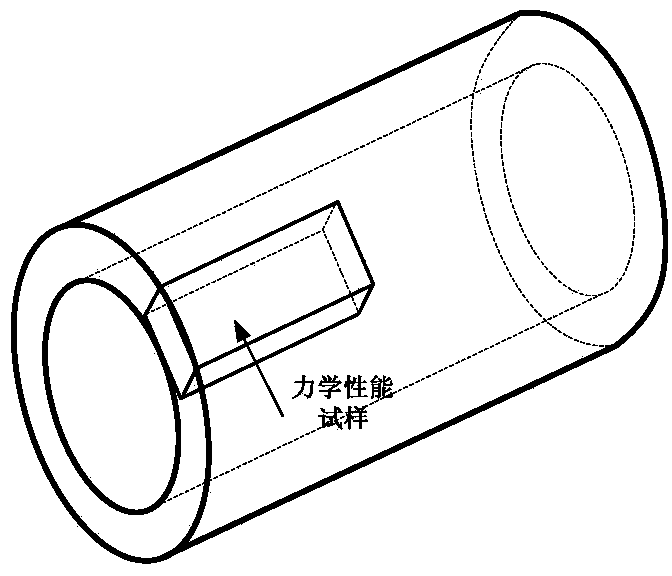

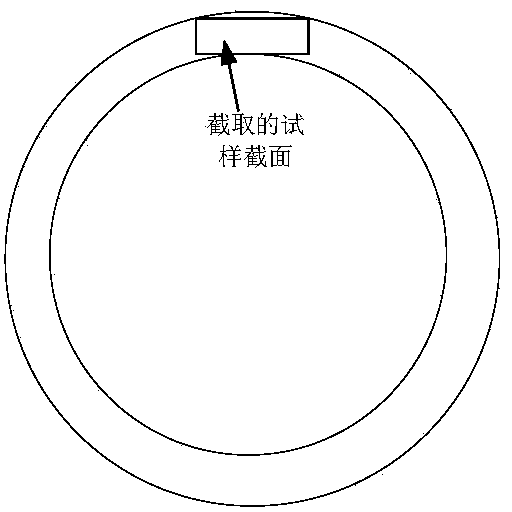

[0055] (1) Cut the sample in the circumferential direction of the pipeline to be tested, and the size is: 150mm×20mm×5mm.

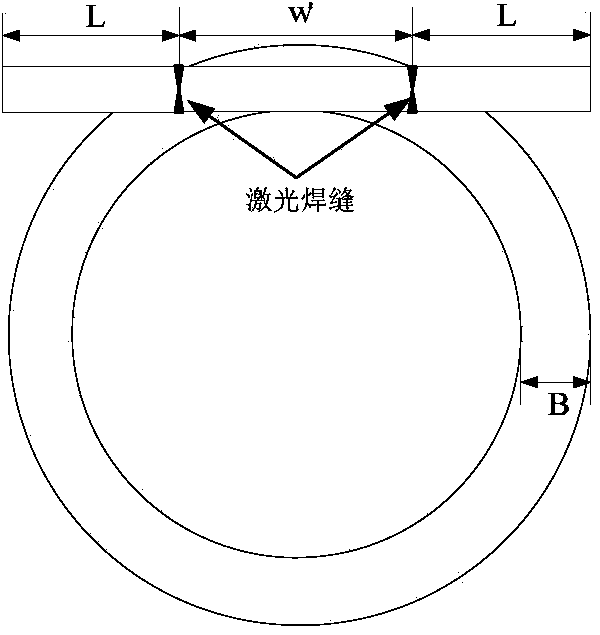

[0056] (2) Laser deep penetration welding to widen the sample. Select welding material Q-235, the size is: 120mm×75mm×6mm. Grind and polish the surface of both sides of the material to be laser welded, and use a laser welder: YLS-4000 to perform laser welding on 20# steel and Q-235 with similar tensile strength. The prepared mechanical properties samples were as 4a- Figure 7b shown.

[0057] Determin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com