50-75 mm-thick 355MPa-grade fracture toughness protecting steel and production method thereof

A technology of fracture toughness and production method, applied in the field of steel material production, can solve the problems of reduced, difficult, and improved welding performance of steel, and achieve the effects of ensuring low-temperature impact performance, stable production process, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

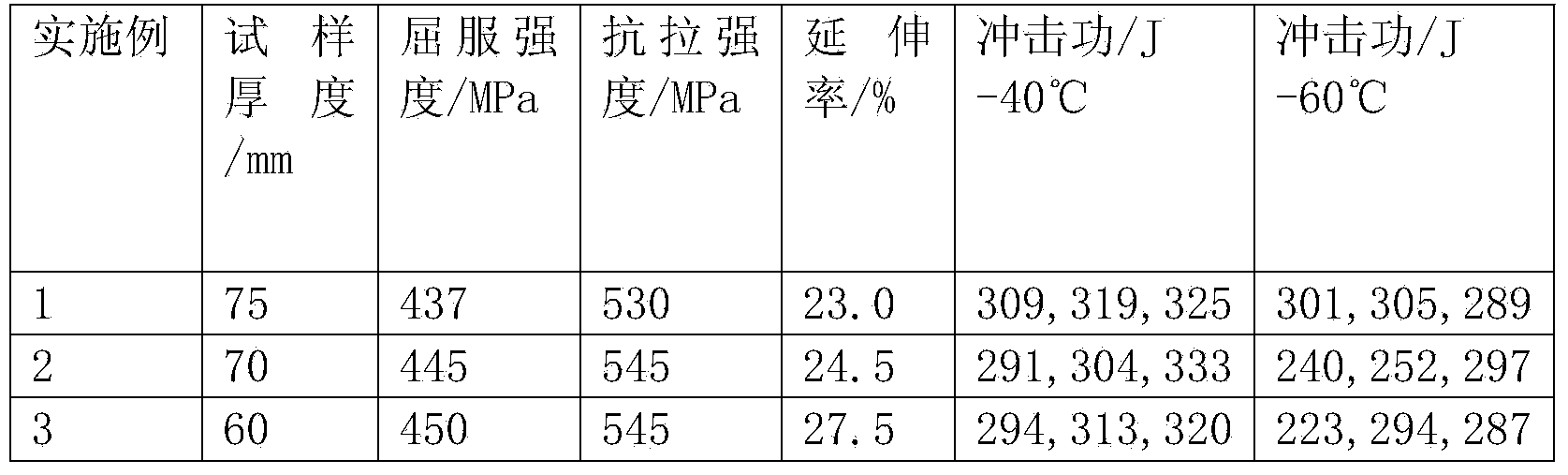

Embodiment 1

[0022] The steel plate includes the following chemical composition in weight percent: C 0.06%, Si 0.25%, Mn 1.51%, P 0.013%, S 0.002%, Ni 0.41%, Nb 0.045%, V 0.026%, Ti 0.012%, the balance Fe and unavoidable impurities. The final microstructure of the steel plate is quasi-polygonal ferrite and bainite.

[0023] The 355MPa fracture toughness guarantee steel includes the following steps: KR hot metal desulfurization pretreatment→converter smelting→deoxidation alloying→CAS refining→LF refining→RH treatment→CCM continuous casting→slab slow cooling for 48h→slab reheating→ Descaling with high-pressure water → controlled rolling → straightening → cooling → cutting, sampling → inspection → spray number printing → storage.

[0024] Among them (1) smelting: hot metal desulfurization ≤ 0.003%; RH refining pure degassing time not less than 6 minutes; soft blowing after RH refining pure degassing is not less than 20 minutes, calcium treatment after vacuum treatment, continuous casting tun...

Embodiment 2

[0031] The steel plate includes the following chemical composition in weight percentage: C 0.07%, Si 0.30%, Mn 1.45%, P 0.011%, S 0.004%, Ni 0.32%, Nb 0.035%, V 0.031%, Ti 0.011%, the balance Fe and unavoidable impurities.

[0032] The 355MPa fracture toughness guarantee steel includes the following steps: KR hot metal desulfurization pretreatment→converter smelting→deoxidation alloying→CAS refining→LF refining→RH treatment→CCM continuous casting→slab slow cooling for 48h→slab reheating→ Descaling with high-pressure water → controlled rolling → straightening → cooling → cutting, sampling → inspection → spray number printing → storage.

[0033]Among them (1) smelting: hot metal desulfurization ≤ 0.003%; RH refining pure degassing time not less than 6 minutes; soft blowing after RH refining pure degassing is not less than 20 minutes, calcium treatment after vacuum treatment, continuous casting tundish target temperature The temperature is 1525~1540℃, and the casting speed is st...

Embodiment 3

[0038] The steel plate includes the following chemical composition in weight percentage: C 0.085%, Si 0.45%, Mn 1.35%, P 0.014%, S 0.002%, Ni 0.38%, Nb 0.020%, V 0.028%, Ti 0.015%, the balance Fe and unavoidable impurities.

[0039] The 355MPa fracture toughness guarantee steel includes the following steps: KR hot metal desulfurization pretreatment→converter smelting→deoxidation alloying→CAS refining→LF refining→RH treatment→CCM continuous casting→slab slow cooling for 48h→slab reheating→ Descaling with high-pressure water → controlled rolling → straightening → cooling → cutting, sampling → inspection → spray number printing → storage.

[0040] Among them (1) smelting: hot metal desulfurization ≤ 0.003%; RH refining pure degassing time not less than 6 minutes; soft blowing after RH refining pure degassing is not less than 20 minutes, calcium treatment after vacuum treatment, continuous casting tundish target temperature The temperature is 1525~1540℃, and the casting speed is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com