460MPa-grade low-compression-ratio and high-toughness steel plate for ocean engineering, and its production method

A low compression ratio, marine engineering technology, applied in the field of iron and steel materials, can solve the problems that the core structure is difficult to guarantee the austenite deformation, it is difficult to achieve a large reduction in the rolling stage, and the heat treatment process cost is high, and it is easy to weld. , The effect of eliminating the internal stress of quenching and strong operability

Inactive Publication Date: 2014-07-23

JIGANG GRP

View PDF4 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, since the method of normalizing usually obtains ferrite plus pearlite structure, the strength is not easy to increase, and it is mainly used to produce marine steel products below 420MPa; while the method of controlled rolling and controlled cooling can obtain high strength, but due to the The thickness is relatively large, and it is difficult to achieve a large reduction in the rolling stage, especially the structure refinement of the core in the rough rolling stage and the austenite deformation in the finishing rolling stage are difficult to guarantee. To ensure toughness under this condition, it is necessary to Larger compression ratio; and the production method of quenching and tempering can improve the strength while ensuring toughness, but compared with the production method of controlled rolling and controlled cooling, when producing steel with the same strength level, the quenching and tempering process needs to be added More alloying elements to ensure strength, which not only leads to cost increase, but also is not conducive to welding, and the cost of quenching and tempering heat treatment process is relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

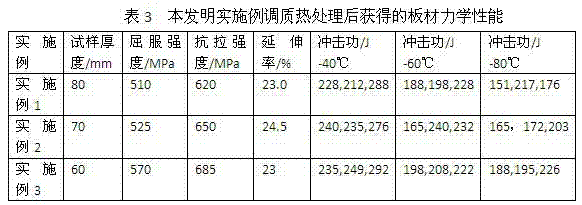

[0034] Example 1: The tempering temperature is 600°C, and the holding time is 180 min.

Embodiment 2

[0035] Example 2: tempering temperature 620, holding time 160 min.

Embodiment 3

[0036] Example 3: tempering temperature 630, holding time 150 min.

[0037] The properties obtained according to the process of the present invention are shown in Table 3.

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

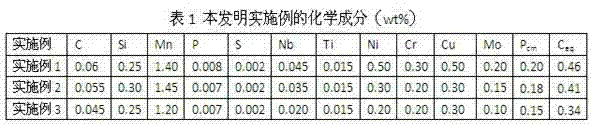

The invention relates to the field of steels material, and concretely relates to a 460MPa-grade low-compression-ratio and high-toughness ocean steel plate and its production method. The steel plate comprises 0.04-0.07wt% of C, 0.2-0.4wt% of Si, 1.0-1.5wt% of Mn, 0.010wt% or less of P, 0.003wt% or less S, 0.2-0.5wt% of Ni, 0.2-0.5wt% of Cu, 0.2-0.4wt% of Cr, 0.1-0.3wt% of Mo, 0.02-0.05wt% of Nb, 0.01-0.025wt% of Ti, and the balance Fe and unavoidable impurities. The C content, the P content and the S content are controlled in a range of 0.04-0.07%, in a range of not greater than 0.010% and in a range of not greater than 0.003% respectively. Even though compression ratio is low, the heating temperature and the rolling temperature are reduced to realize the recrystallization refinement of austenite grains and ensure the low-temperature impact performance, and tempering after rolling further improves the toughness and the microstructure uniformity. The steel plate produced by the above scheme has a tensile strength of 620- 685MPa, a yield strength of 500-570MPa and a fracture elongation of 20-25%, has (horizontal) Charpy impact energy at -60DEG C reaching 240J, has a -80DEG C low temperature impact of not lower than 150J, has a Pcm value of not greater than 0.22 and a Ceq value of not greater than 0.47, and has the characteristics of easy welding, stable production process, strong operability and the like.

Description

technical field [0001] The invention relates to the field of iron and steel materials, in particular to a 460MPa grade low compression ratio high toughness steel plate for marine engineering and a production method thereof. Background technique [0002] Marine rights and interests are one of the core interests of our country. In recent years, the implementation of the national marine strategy has made marine engineering the focus of construction and development, and has gradually developed from the offshore to the deep sea. The rapid development of the ocean engineering equipment industry will create a huge demand for steel for ocean engineering, especially with the large-scale, high-parameterization, and lightweight of ships, ocean engineering, port machinery, and submarine oil pipelines, the performance of steel is raised. higher and higher requirements. In recent years, Japan’s Nippon Steel and JFE, Germany’s Dillingen, etc. are at the forefront of the world’s steel comp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/50C21D8/02

Inventor 朱延山李秀程李敏孙卫华徐洪庆李旺生杜平王涣洋王勇田德科

Owner JIGANG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com