Strain design region based high-performance pipeline steel with high-deformation resistance and preparation method

A large deformation resistant and high performance technology, applied in the fields of large deformation resistant pipeline steel, oil and gas pipeline engineering construction, high performance large deformation resistant pipeline steel and its preparation, to achieve excellent large deformation resistance, low temperature toughness and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

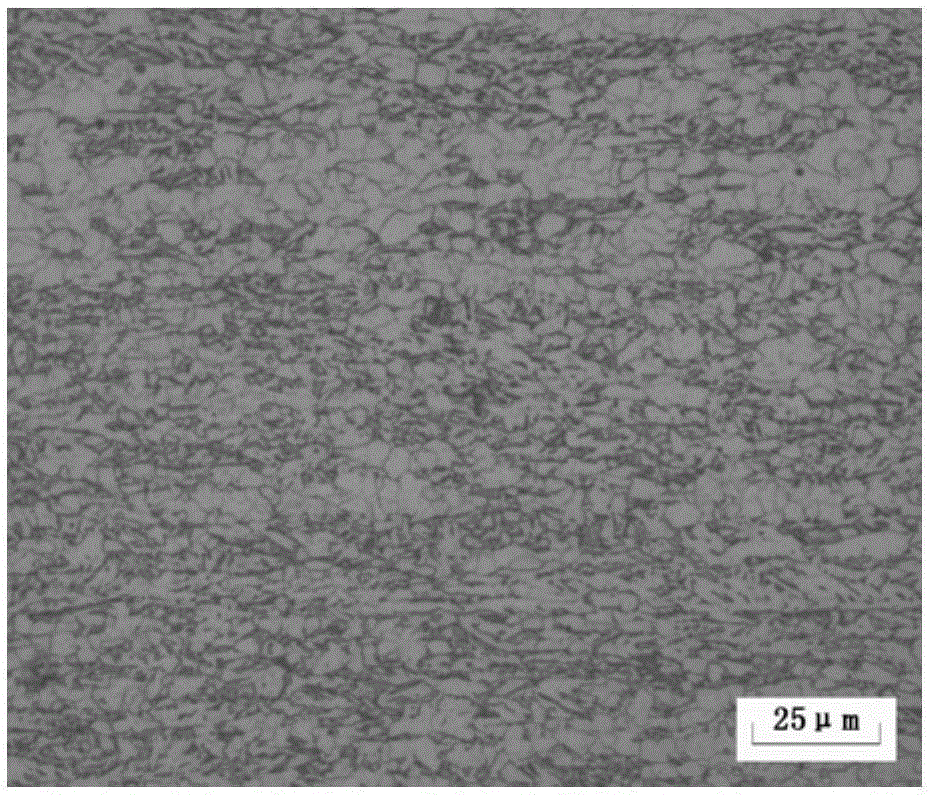

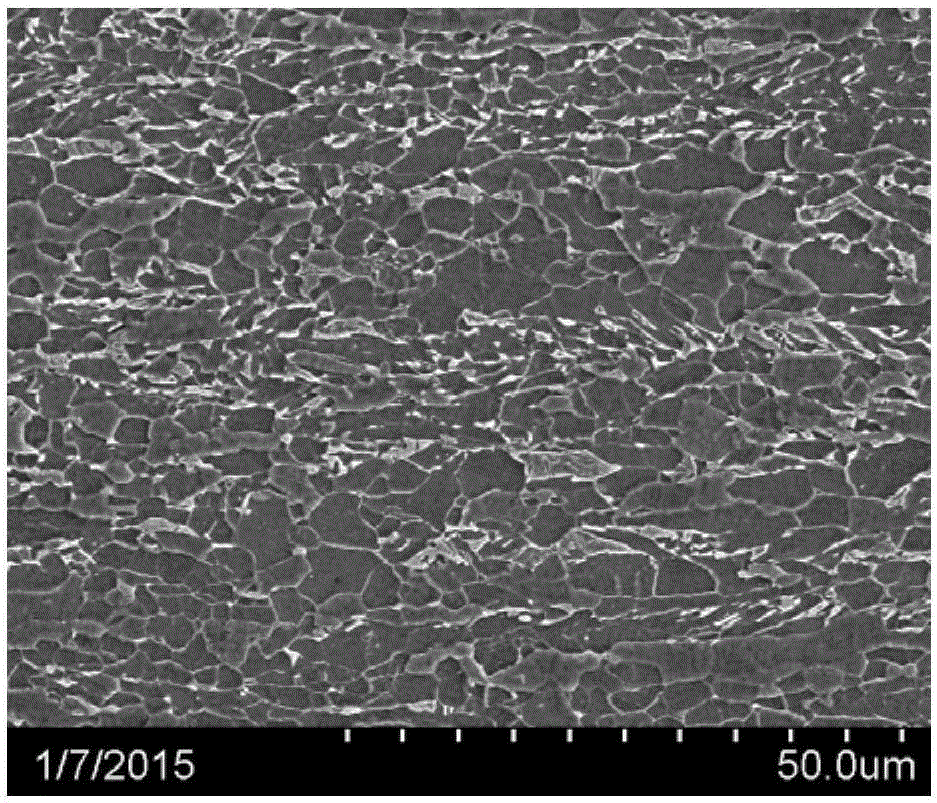

Image

Examples

Embodiment Construction

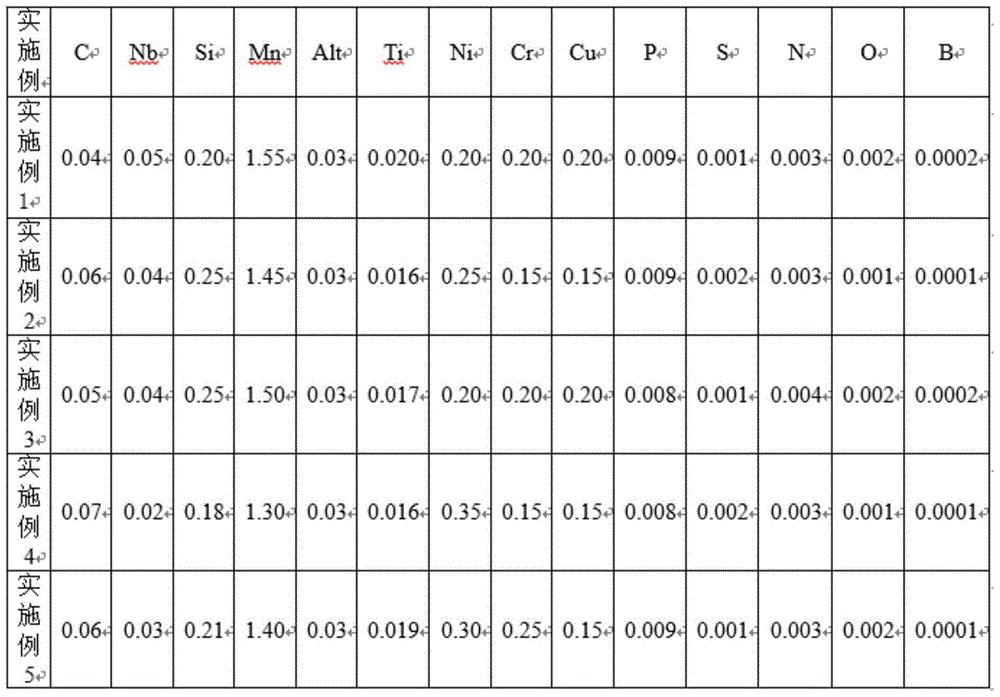

[0032] According to the present invention, the high-performance large-deformation-resistant pipeline steel and its production method are smelted on a 100-ton converter, controlled rolling and controlled cooling are performed on a 4300mm production line, and tubes are made through a JCOE / UOE production line, using a semi-automatic flux-cored wire self-shielded welding process. Circumferential seam welding. The present invention will be further described below by way of examples. In the embodiment, the chemical composition of the steel plate is shown in Table 1, the process system of the embodiment is shown in Table 2, and the mechanical properties of the embodiment are shown in Table 3:

[0033] Example chemical composition

[0034] Table 1. Chemical composition (wt%) of the embodiment of the high-performance large-deformation-resistant pipeline steel of the present invention

[0035]

[0036] Among them, in Examples 1-5, C+Nb is controlled in the range of 0.08-0.10%, Cr+C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com