Grade X80 pipe line steel with low yield ratio and manufacturing method thereof

A technology with low yield ratio and manufacturing method, which is applied in the field of metallurgy, can solve problems such as weak resistance to deformation, and achieve the effects of increasing strength, improving rolling rhythm, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

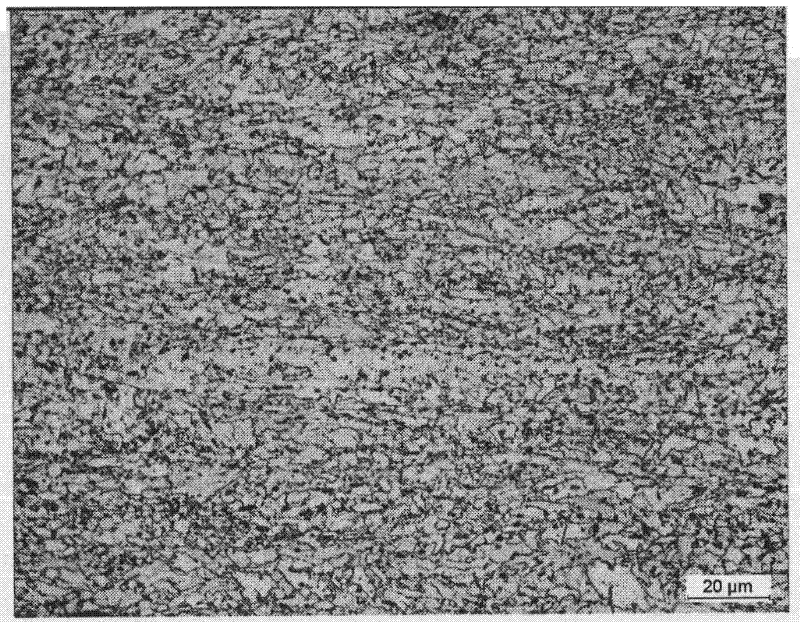

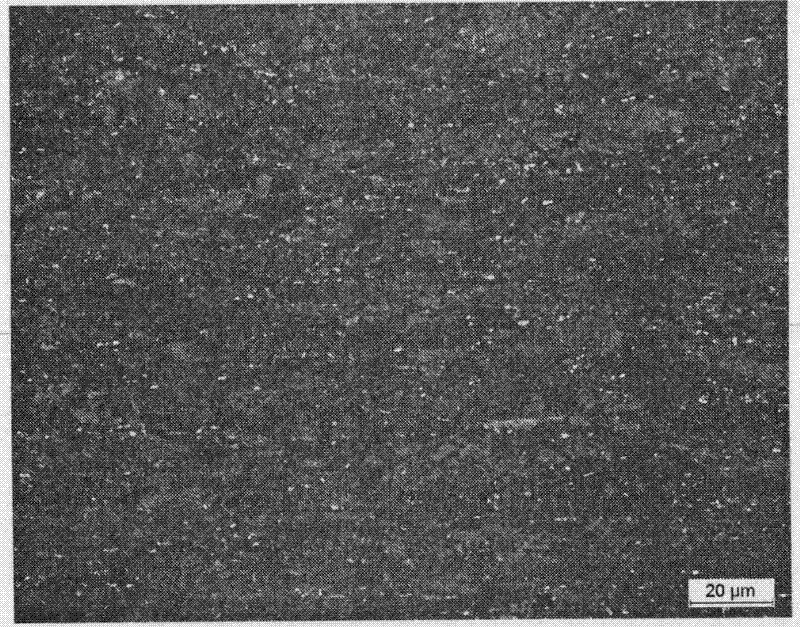

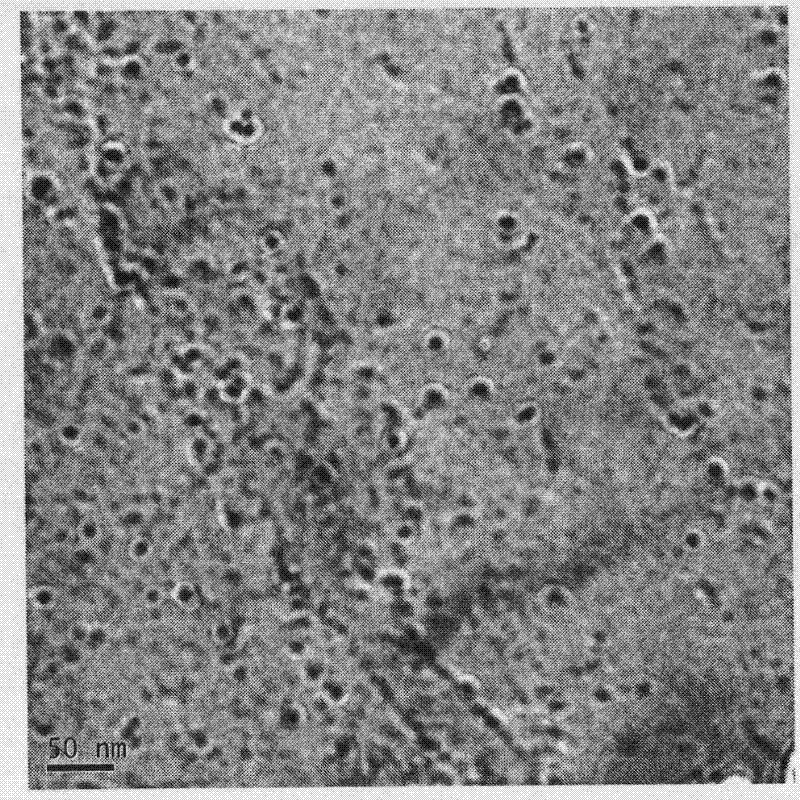

Image

Examples

Embodiment 1

[0027] Smelting and pouring into slab according to the set composition, the composition of the slab by weight percentage is: C 0.047%, Si 0.22%, Mn1.89%, S 0.002%, P 0.004%, Al 0.04%, Cu 0.22%, Cr 0.26%, Ni 0.25%, Nb 0.1%, V 0.057%, Ti 0.022%, Mo 0.23%, N 0.0035%, and the rest is Fe.

[0028] Heat the billet to 1180°C and keep it warm for 1h.

[0029] The slab is rolled in two stages, the first rolling temperature is 1150℃, the total reduction is 62.5%; the second rolling temperature is 921℃, the final rolling temperature is 856℃, the second The total reduction of the stage is controlled at 72%.

[0030] After rolling, cool to 710°C at a cooling rate of 80°C / s, air cool for 4 seconds, then cool to 460°C at a cooling rate of 24°C / s; air cool to room temperature.

[0031] The finished product thickness of X80 pipeline steel is 16mm, the yield strength is 585MPa, the tensile strength is 740MPa, the yield strength ratio is 0.790, the elongation after fracture is 18.9%, and the i...

Embodiment 2

[0034] Smelting and pouring into slab according to the set composition, the composition of the slab by weight percentage is C 0.024%, Si 0.24%, Mn1.89%, S 0.002%, P 0.012%, Al 0.035%, Cu 0.22%, Cr 0.08 %, Ni 0.24%, Nb 0.081%, V 0.03%, Ti 0.012%, Mo 0.29%, N 0.003%, Ca 0.0018%, and the rest is Fe.

[0035] Heat the slab to 1200°C and keep it warm for 1.5h.

[0036] The slab is rolled in two stages, the first rolling temperature is 1130℃, the total reduction is 62%; the second rolling temperature is 940℃, the final rolling temperature is 840℃, the second The total reduction of the stage is controlled at 68.4%.

[0037] After rolling, cool to 600°C at a cooling rate of 96°C / s, air cool for 5 seconds, then cool to 490°C at a cooling rate of 18°C / s; air cool to room temperature.

[0038] The finished product thickness of X80 pipeline steel is 12mm, the yield strength is 595MPa, the tensile strength is 745MPa, the yield strength ratio is 0.799, the elongation after fracture is 21....

Embodiment 3

[0041] Smelting and pouring into slab according to the set composition, the composition of the slab by weight percentage is: C 0.06%, Si 0.27%, Mn1.62%, S 0.0019%, P 0.0049%, Al0.045%, Cu 0.15%, Cr 0.11%, Ni 0.25%, Nb 0.072%, V 0.045%, Ti 0.022%, Mo 0.22%, N 0.0043%, and the rest is Fe.

[0042]The billet was heated to 1220°C and kept for 2h.

[0043] The casting billet is rolled in two stages. The first stage rolling temperature is 1100 ° C, and the total reduction is 62%; the second rolling stage rolling temperature is 930 ° C, the final rolling temperature is 845 ° C, and the second rolling The total reduction of the stage is controlled at 68.4%.

[0044] After the rolling is completed, it is cooled to 610°C at a cooling rate of 98°C / s, air-cooled for 18 seconds, and then cooled to 340°C at a cooling rate of 30°C / s; air-cooled to room temperature.

[0045] The thickness of X80 grade pipeline steel is 12mm, the yield strength is 685MPa, the tensile strength is 860MPa, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com