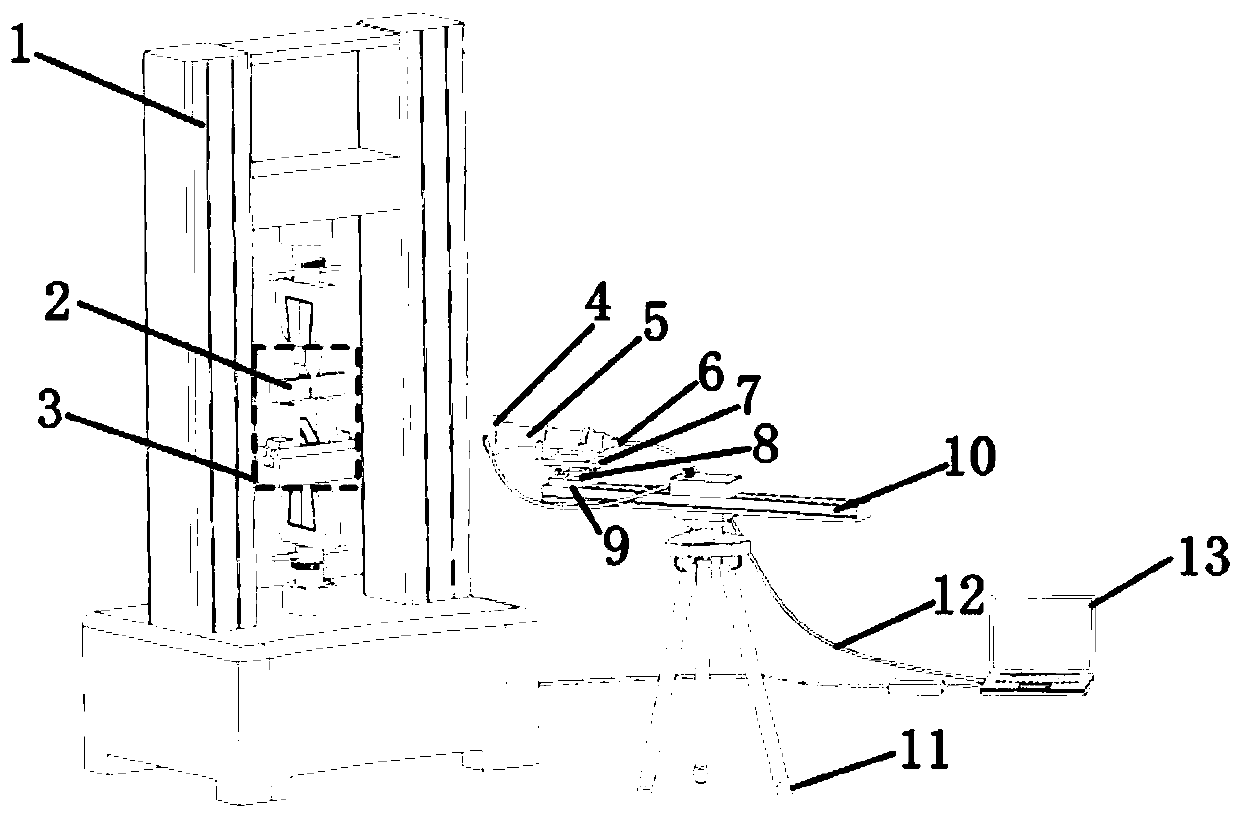

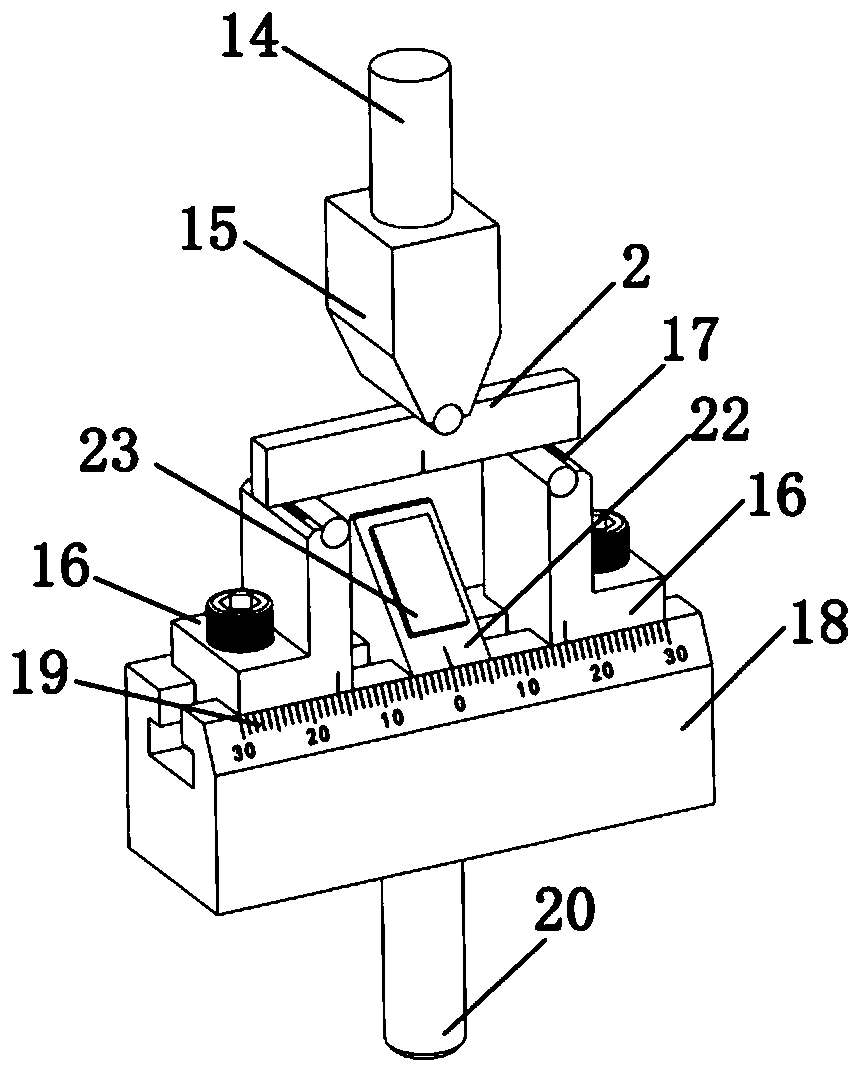

Non-contact crack opening displacement measuring device and method for bending fracture test

A technology of opening displacement and bending fracture, which is applied in the direction of testing the strength of materials by applying a stable bending force, can solve the problems of difficulty in measuring opening displacement, increasing the difficulty of heat insulation, low-temperature dielectric loss, and limited range, etc., to achieve flexible use, Convenient bending fracture test, wide measurement range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

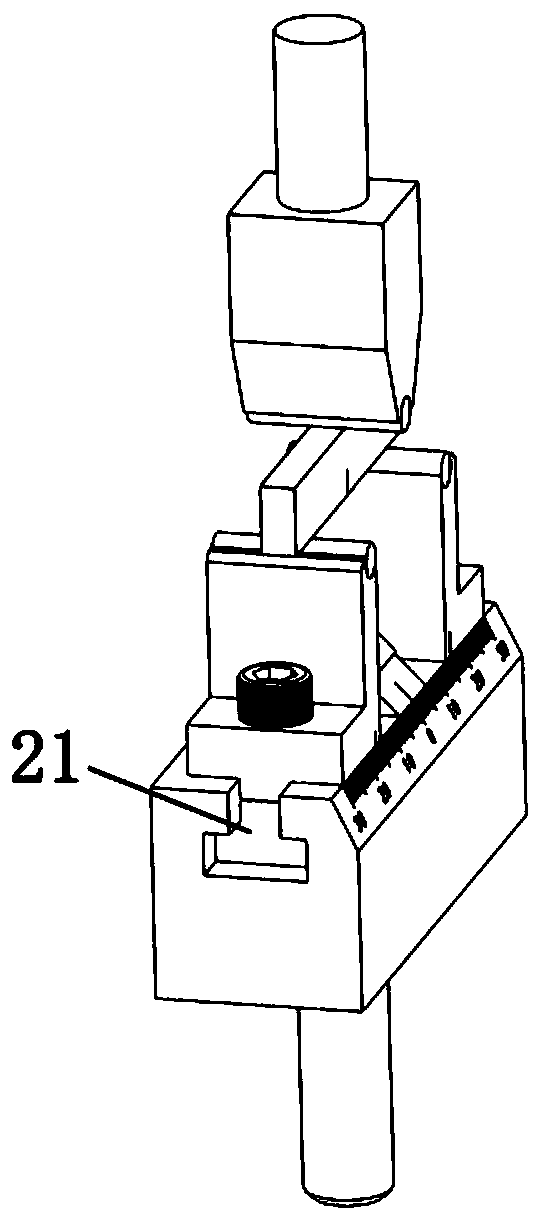

Method used

Image

Examples

Embodiment

[0073] The following uses a tungsten alloy as an example to introduce the application process of the present invention.

[0074] 1. Material description: The material in the examples is tungsten alloy after deformation processing. Due to the limitations of the processing technology, larger volume blocks cannot be prepared, and conventional measurement methods cannot effectively measure the fracture toughness of the material.

[0075] 2. Test item: Fracture toughness K of brittle materials IC test.

[0076] 3. Sample type: three-point bending sample, the length is about 22mm, the span S=16mm, and the crack notch depth a is cut out in advance 0 About 1mm.

[0077] 4. Imaging system parameters: the magnification of the selected imaging lens is 2 times, and the digital resolution of the industrial camera is

[0078] 2048×1088 pixels, the physical size of a single pixel of the image collected by the optical measurement system is 2.904 μm.

[0079] 5. Test method: refer to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com