Patents

Literature

34results about How to "Adjustable span" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

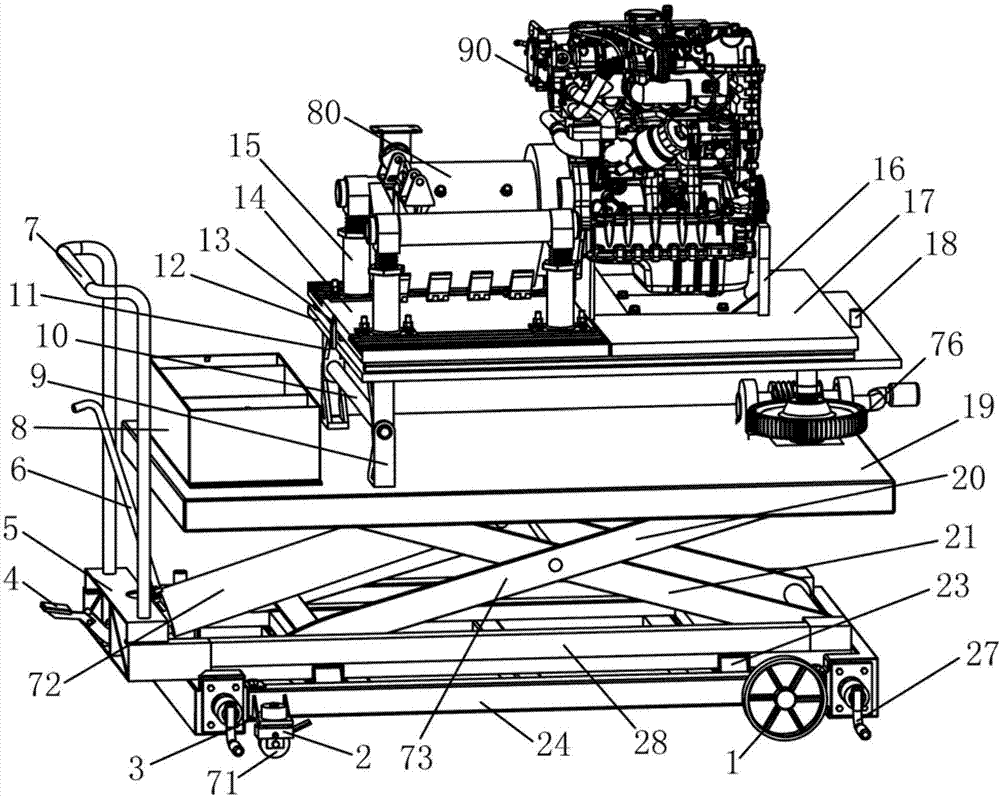

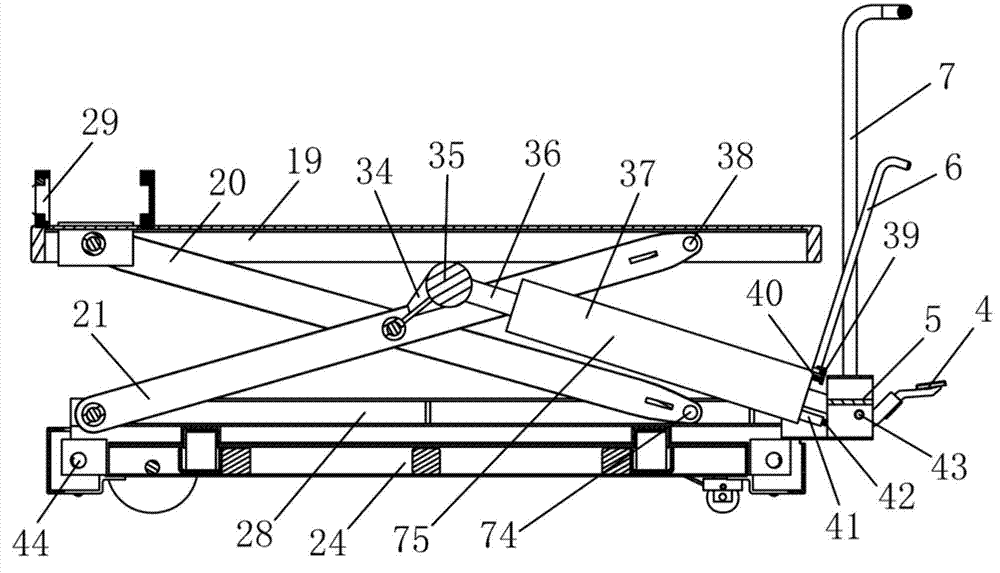

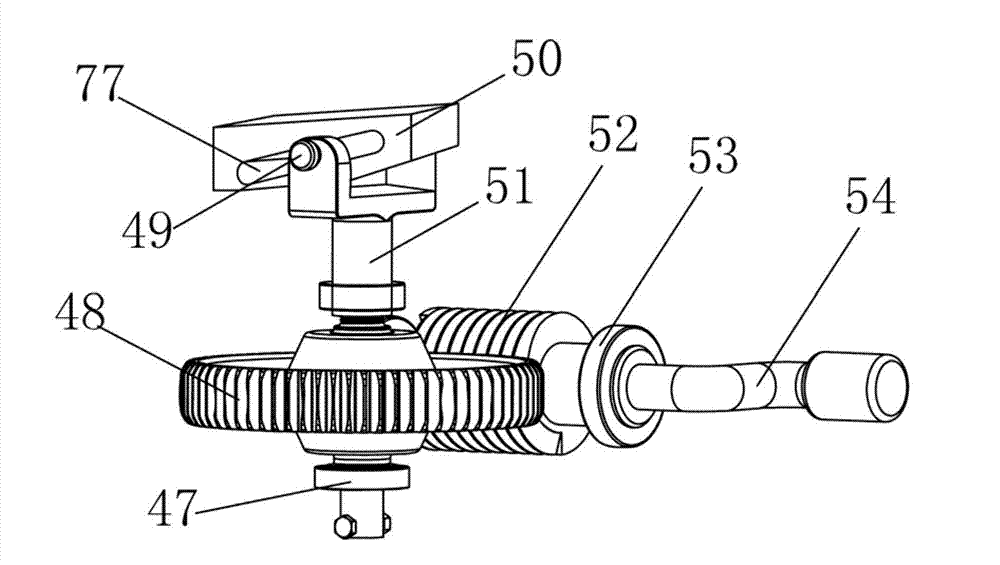

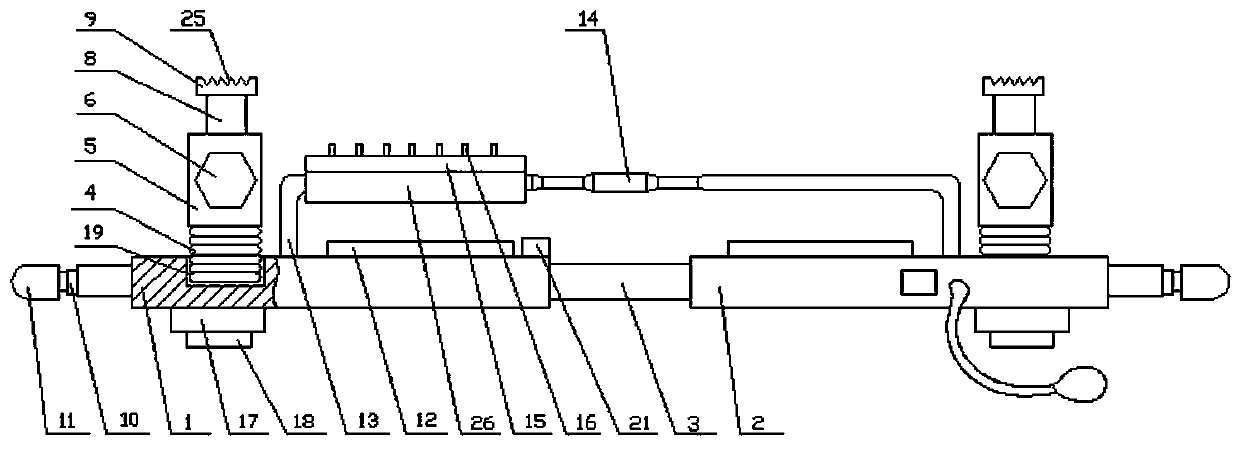

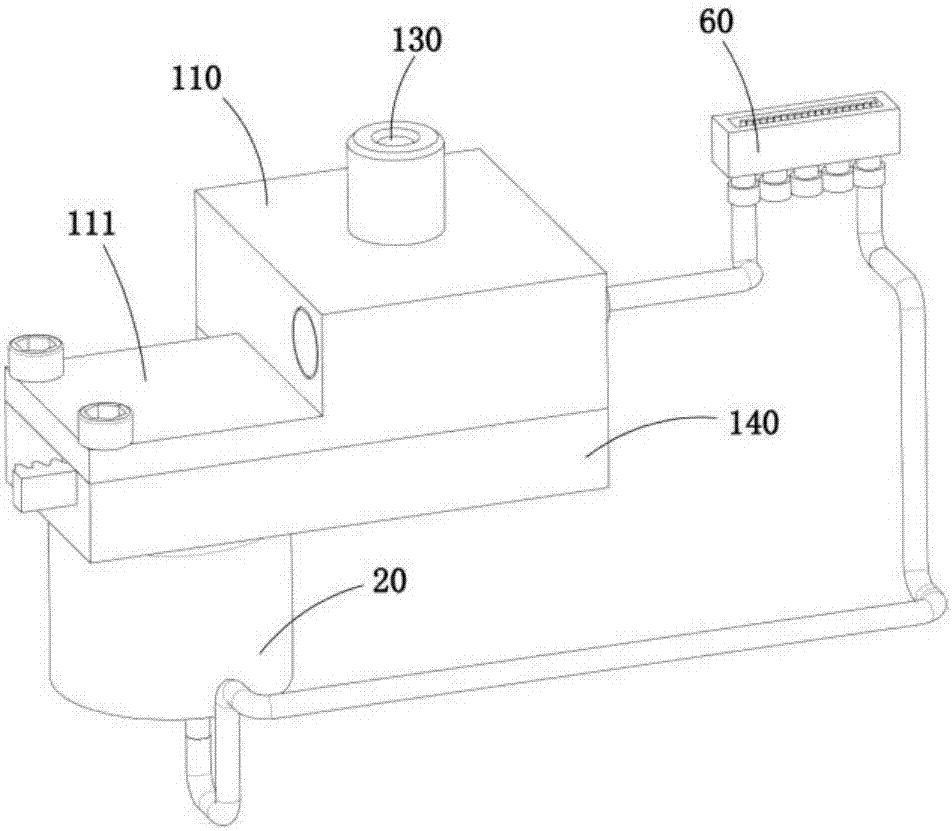

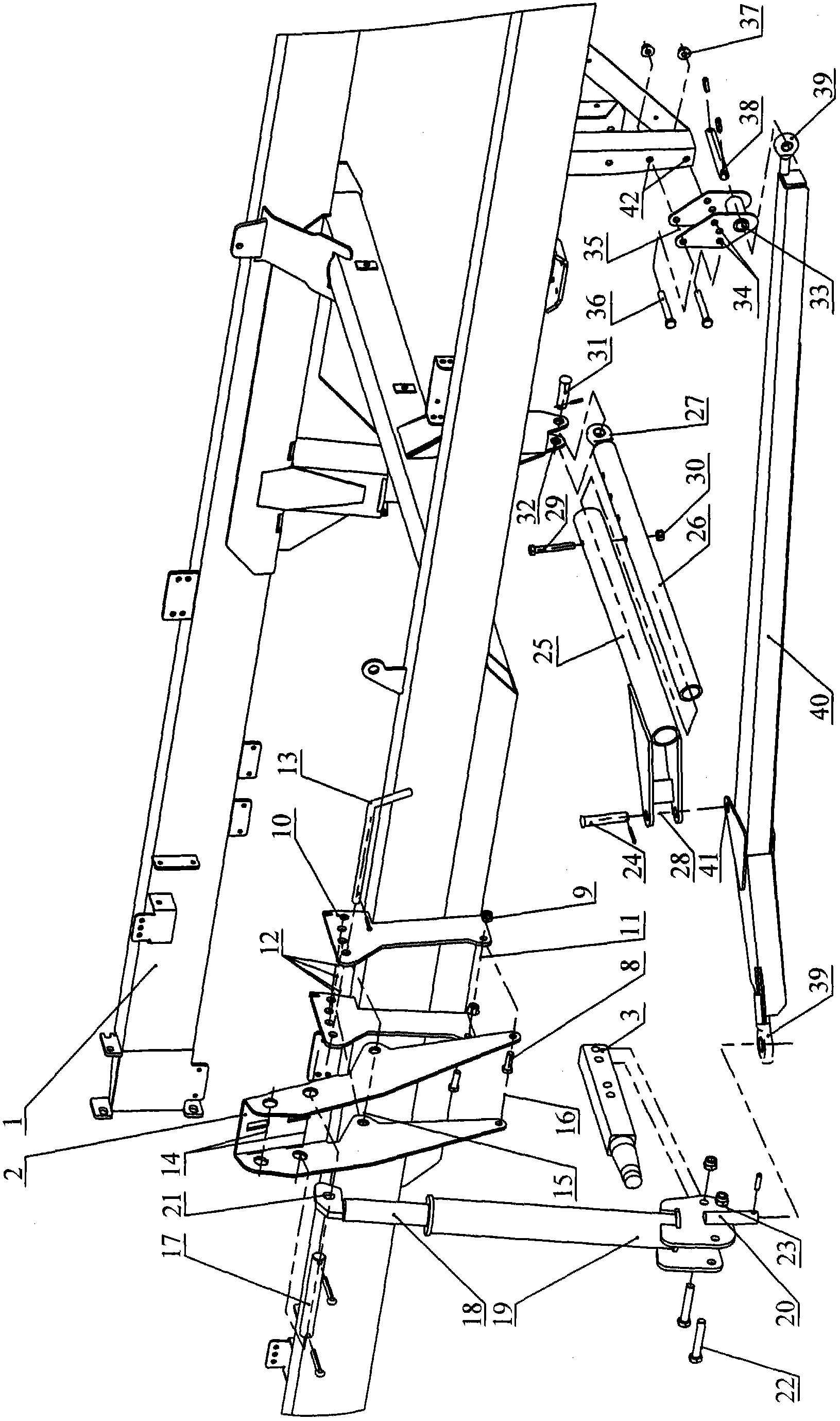

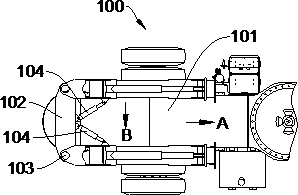

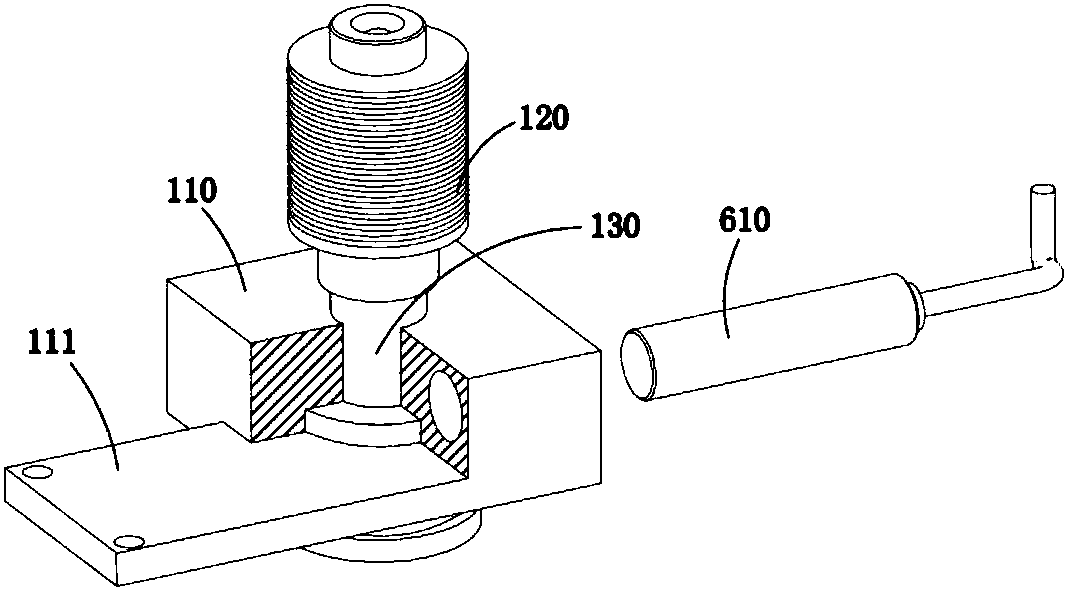

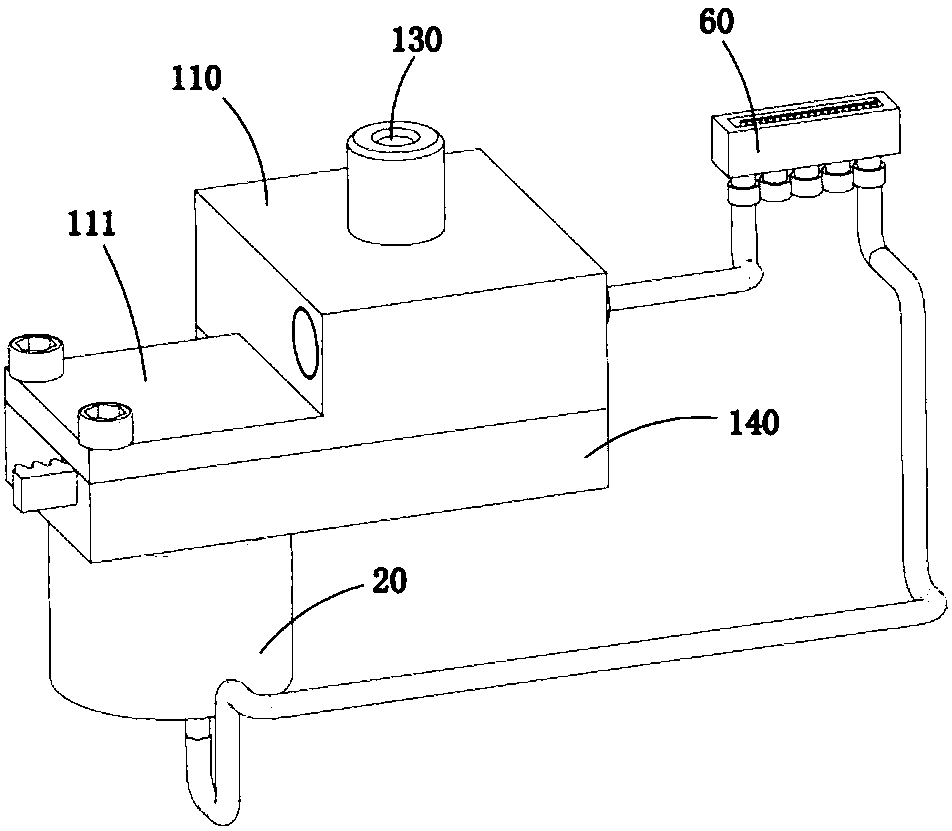

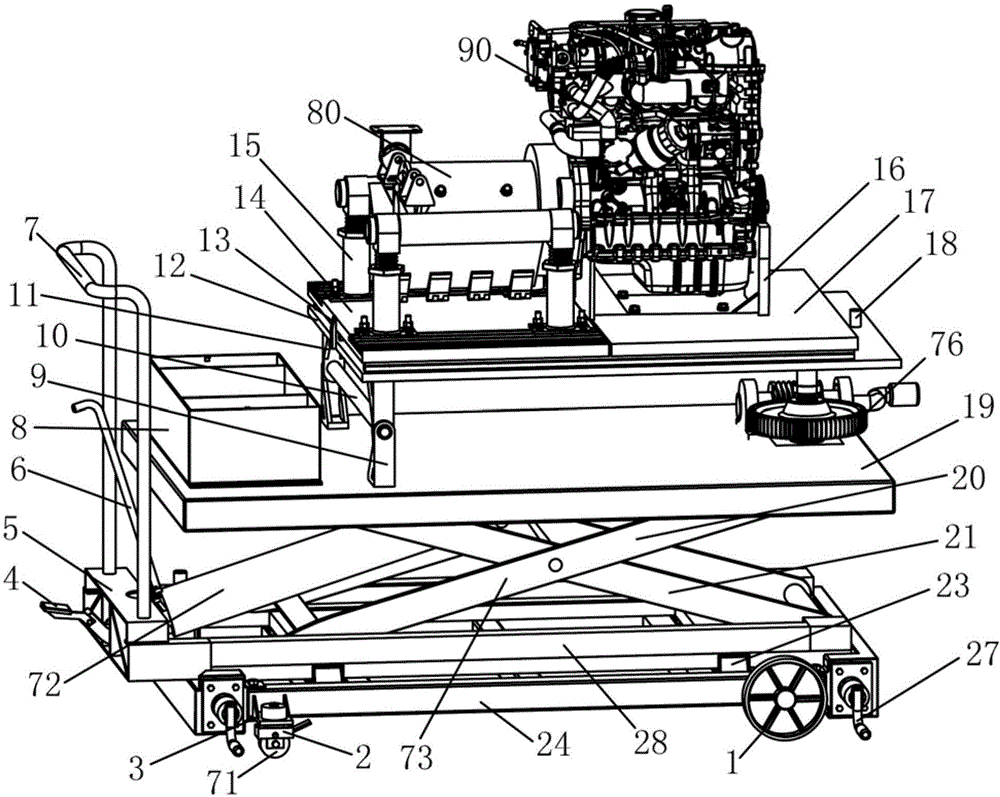

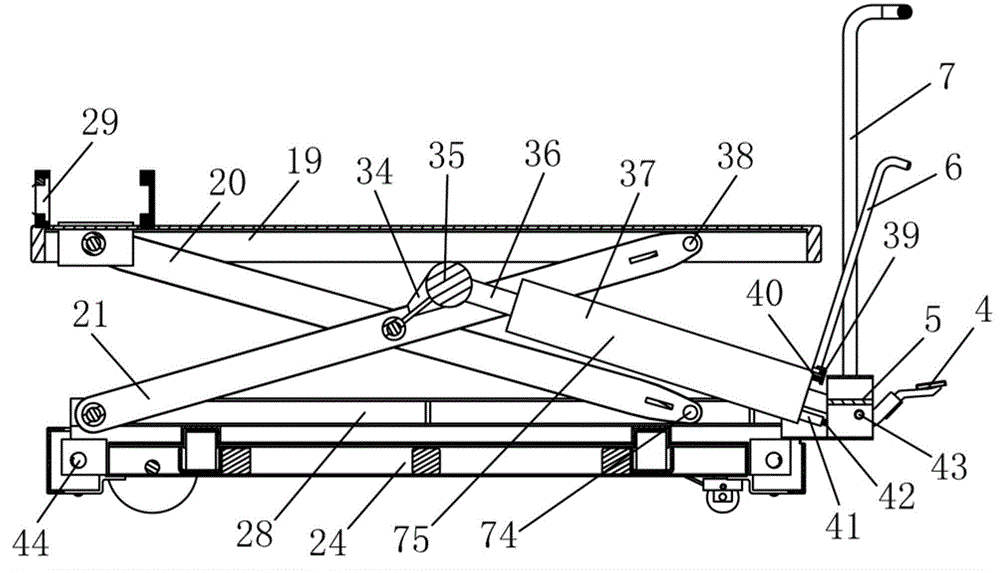

Multifunctional assembly and disassembly equipment for parts of dynamical system of new energy vehicles

InactiveCN103111992AAccurate and easy disassemblyIngenious designWork benchesVehicle frameNew energy

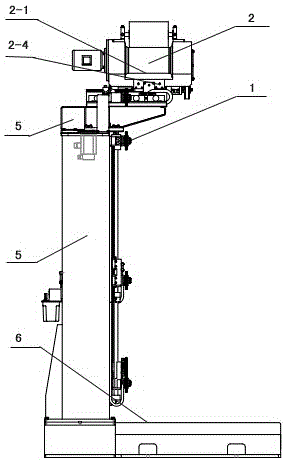

The invention relates to a multifunctional assembly and disassembly equipment for parts of a dynamical system of new energy vehicles. Bottom wheels can be rotatably installed beneath a chassis and support the chassis. An auxiliary vehicle frame is supported on the chassis and is arranged in a left and right moving mode relative to the chassis. A top plate is supported on the auxiliary vehicle frame and is arranged in an up and down moving mode relative to the auxiliary vehicle frame. A support platform is rotatably arranged on the top plate by rotating around the rear end. A motor support installation platform and a replaceable support installation platform are arranged adjacent to each other and are both arranged on the support platform in a front and back moving mode. A motor support is arranged on the motor support installation platform, a replaceable support is arranged on the replaceable support installation platform, and the replaceable support is an engine support or a gearbox support. The multifunctional assembly and disassembly equipment for parts of the dynamical system of new energy vehicles is ingenious in design, enables assembly and disassembly of parts of the dynamical system of new energy vehicles to be accurate, simple and convenient, greatly simplifies an installation process, reduces investment on manpower and material resources, decreases the number of times of adjustment, greatly improves work efficiency and is suitable for large-scale popularization and application.

Owner:JIANGXI B ENERGY SHANGRAO COACH

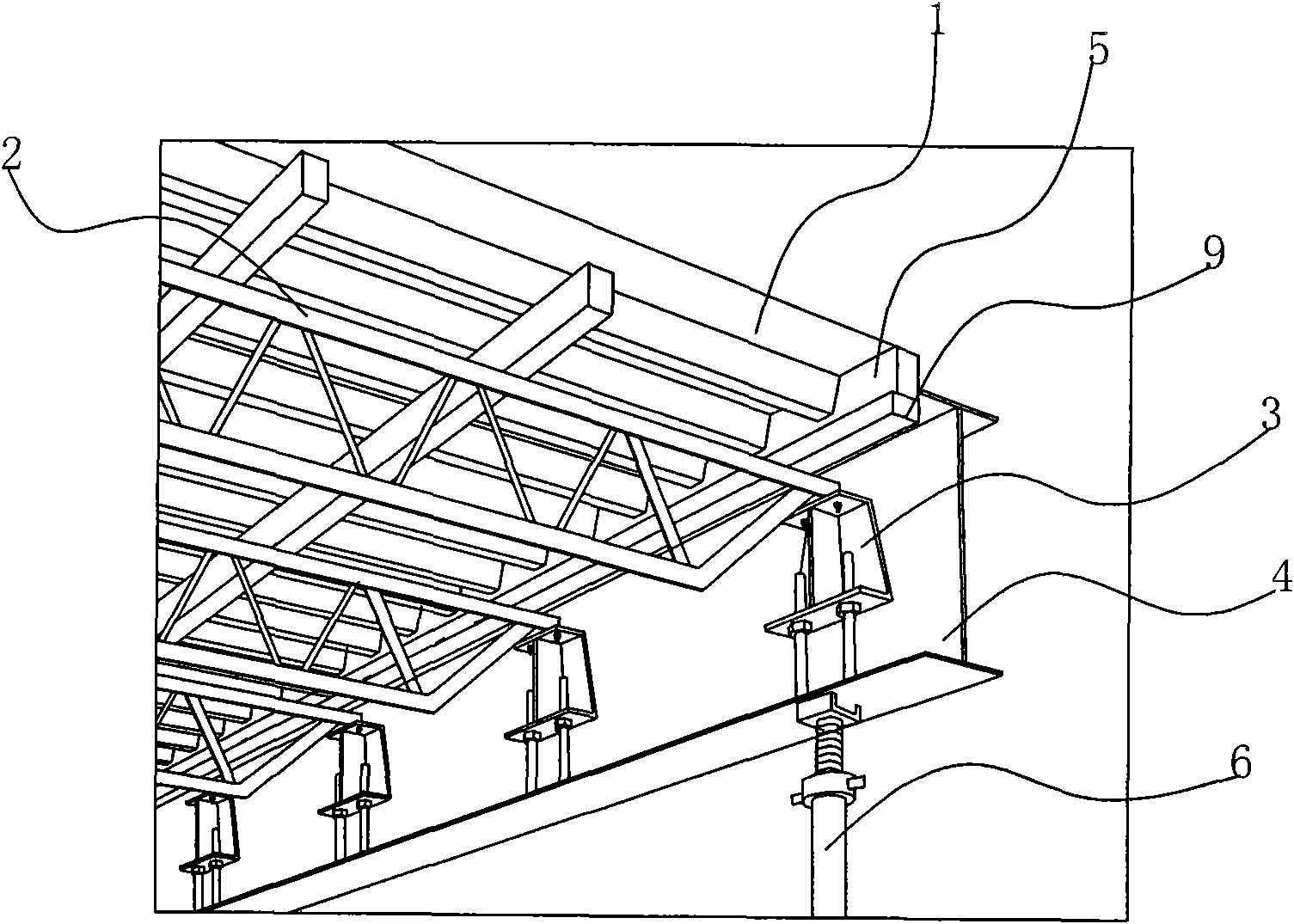

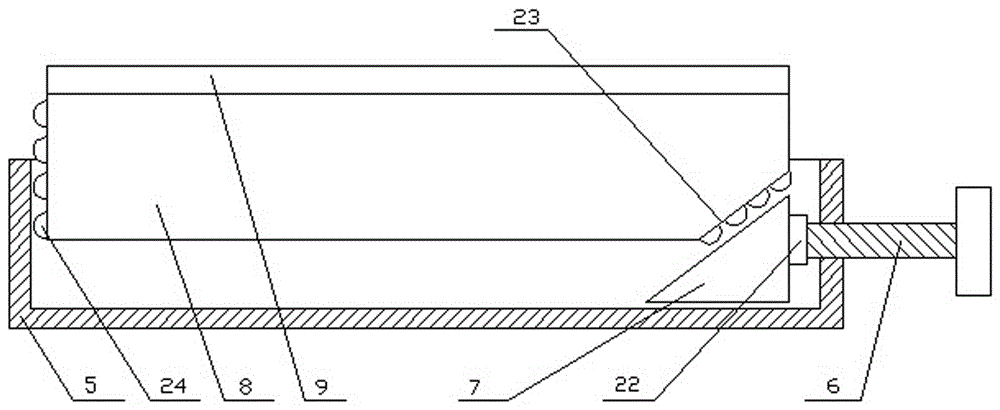

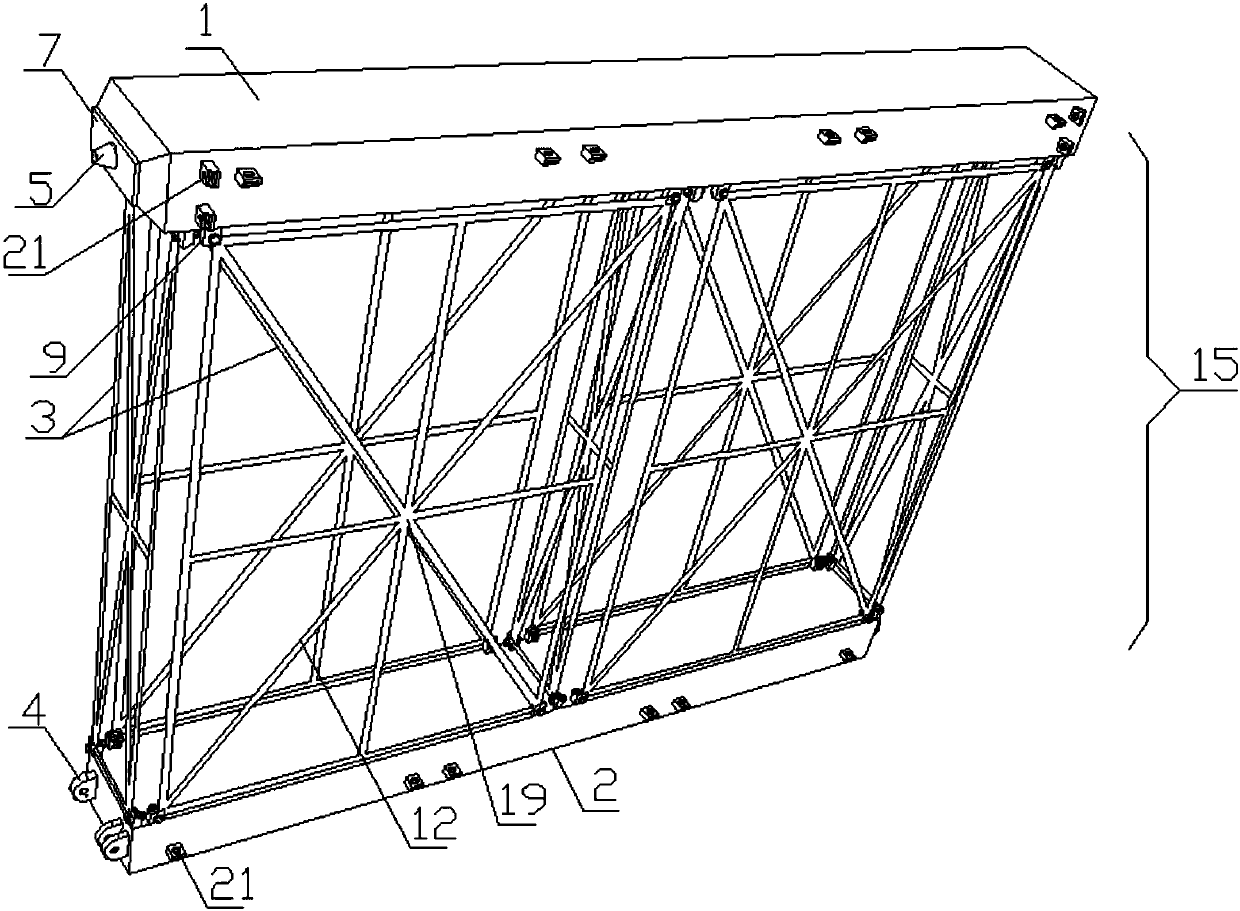

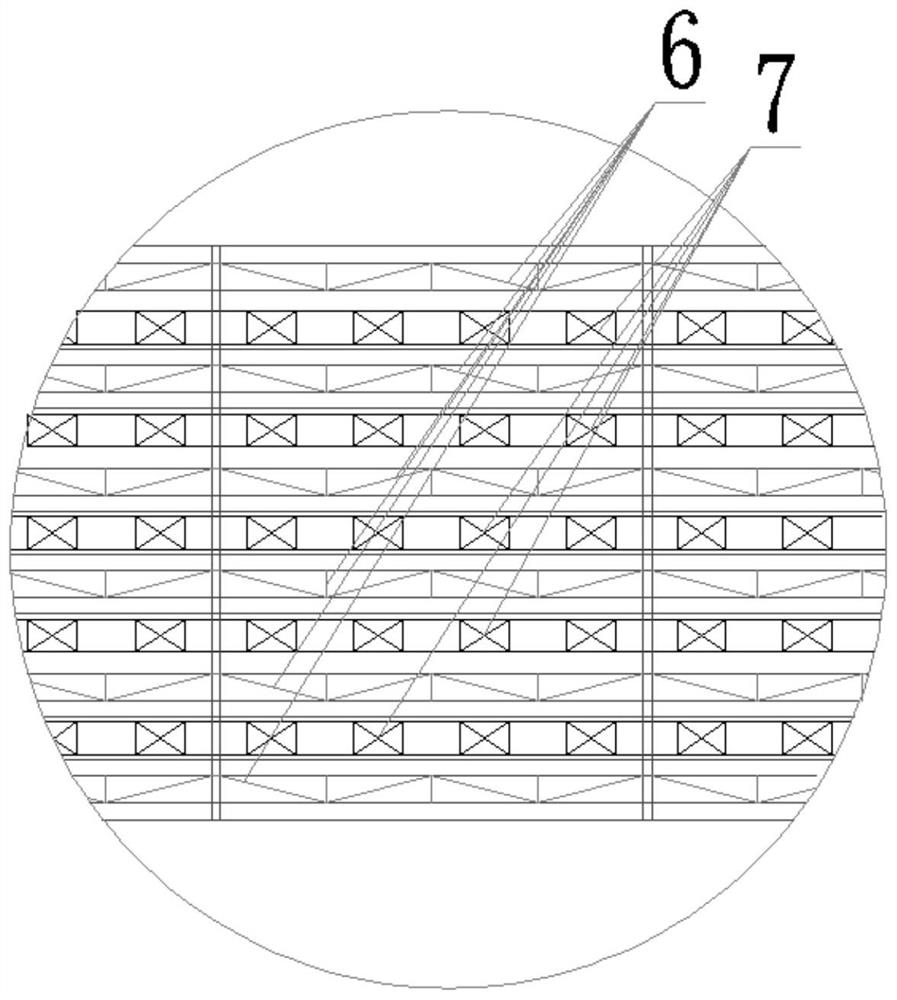

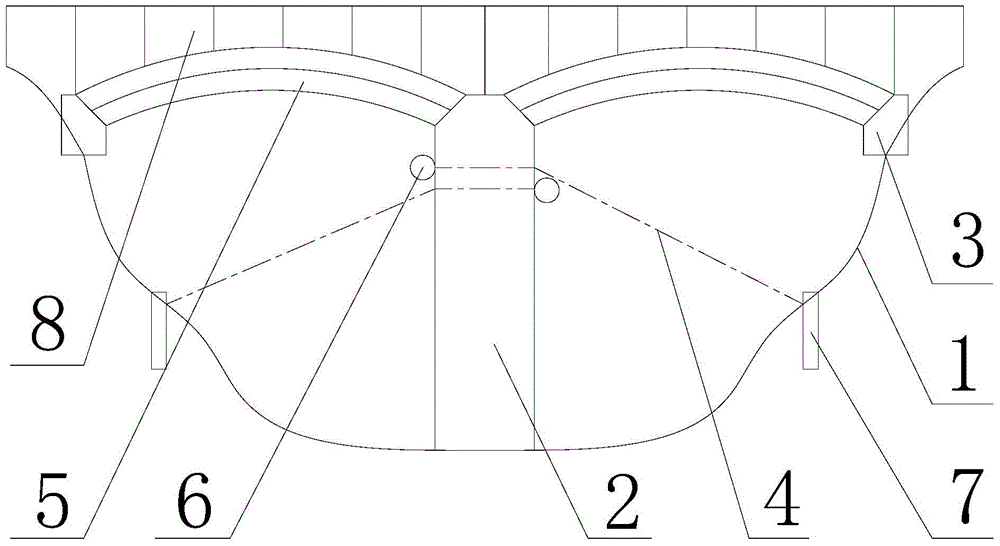

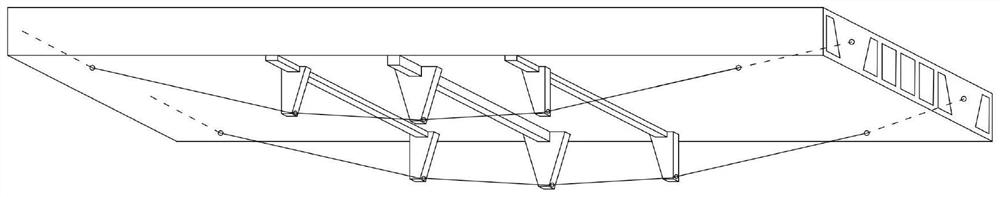

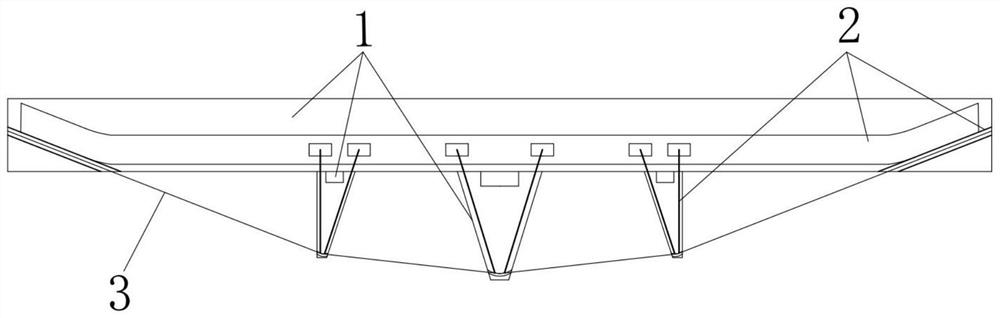

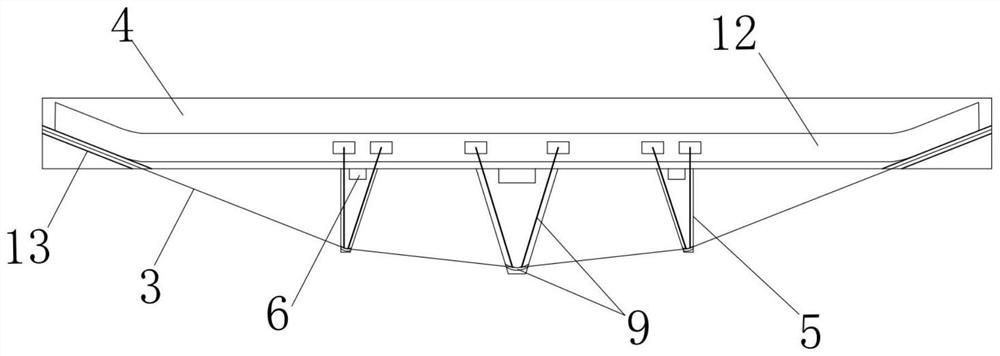

Long-slab-span steel beam cast-in-situ floor formwork system

The invention discloses a long-slab-span steel beam cast-in-situ floor formwork system, which comprises a floor template, an adjustable truss and an adjustable placement support seat for supporting the adjustable truss, wherein a grille is laid on the adjustable truss; the floor template is laid on the grille; the adjustable placement support seat is arranged on a lower flange of a transverse H-shaped steel beam; and the adjustable truss is a telescopic combined truss and is connected with the upper end of the adjustable placement support seat. Compared with the conventional normal truss formwork system, the long-slab-span steel beam cast-in-situ floor formwork system provided according to the invention has the advantages of adjustable span, adjustable height and suitability for different beam heights; the adaptability of the truss is greatly improved; and the formwork cost is greatly lowered.

Owner:杨峰

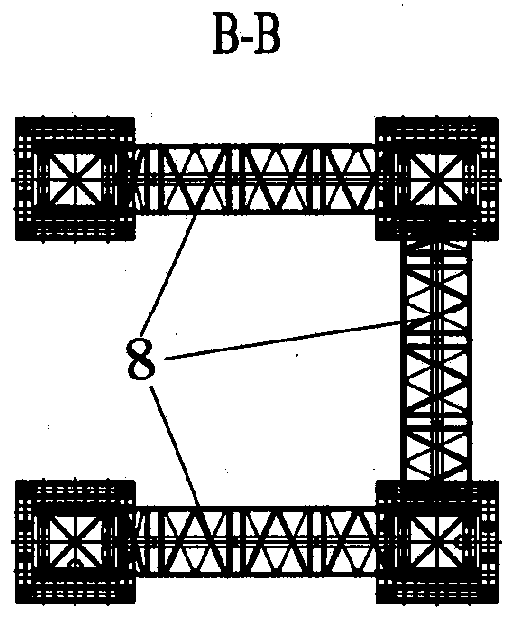

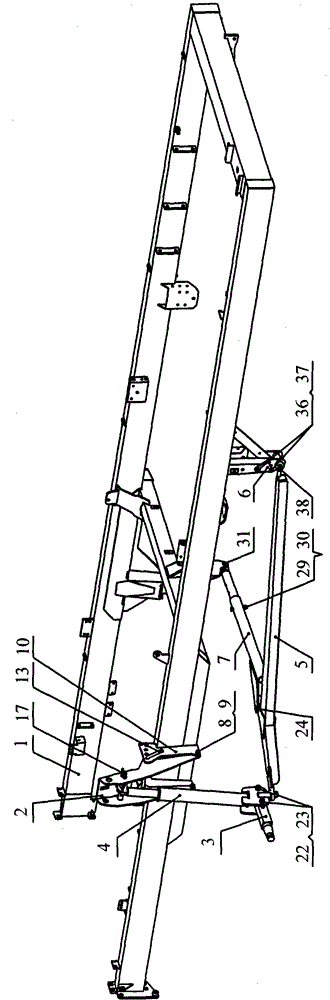

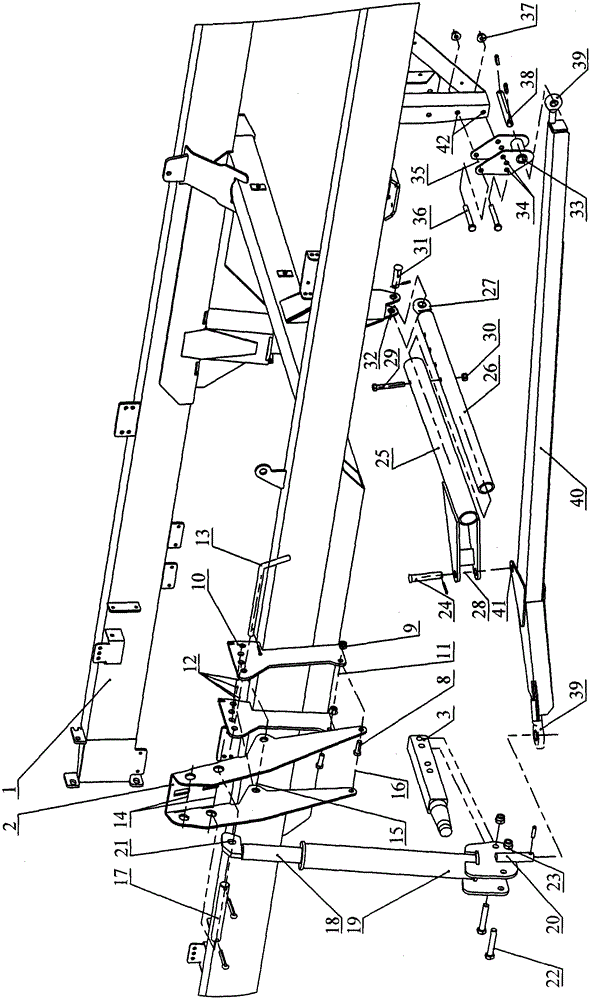

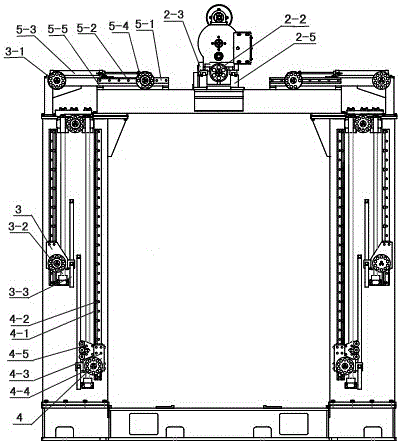

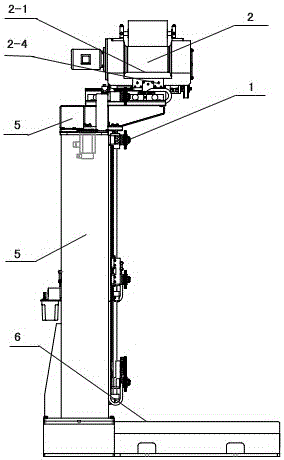

Hydraulic double-type crane and mounting method

ActiveCN103723624AAdjustable spanBase supporting structuresBraking devices for hoisting equipmentsEngineering

Owner:TAIYUAN HEAVY IND +1

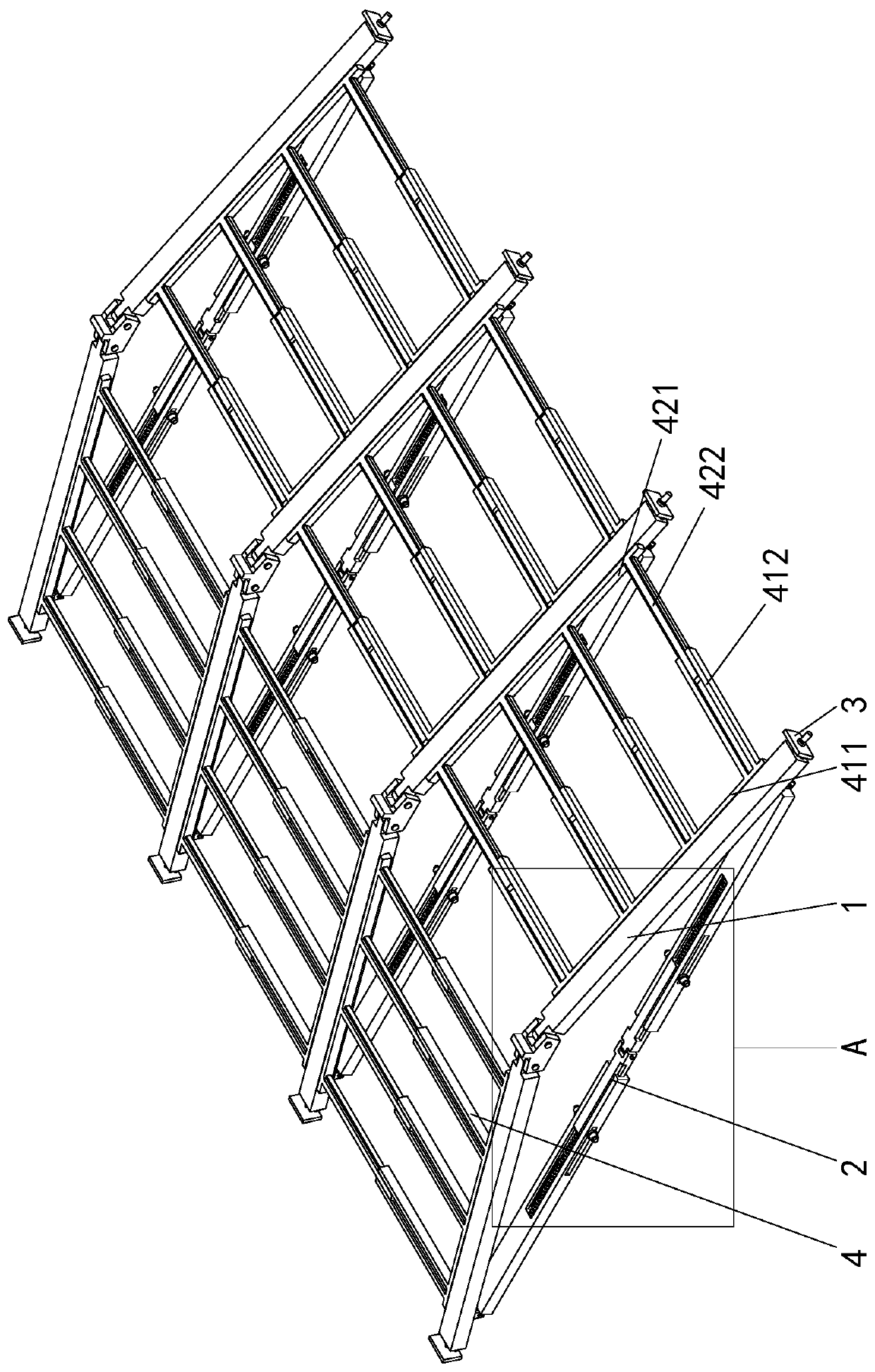

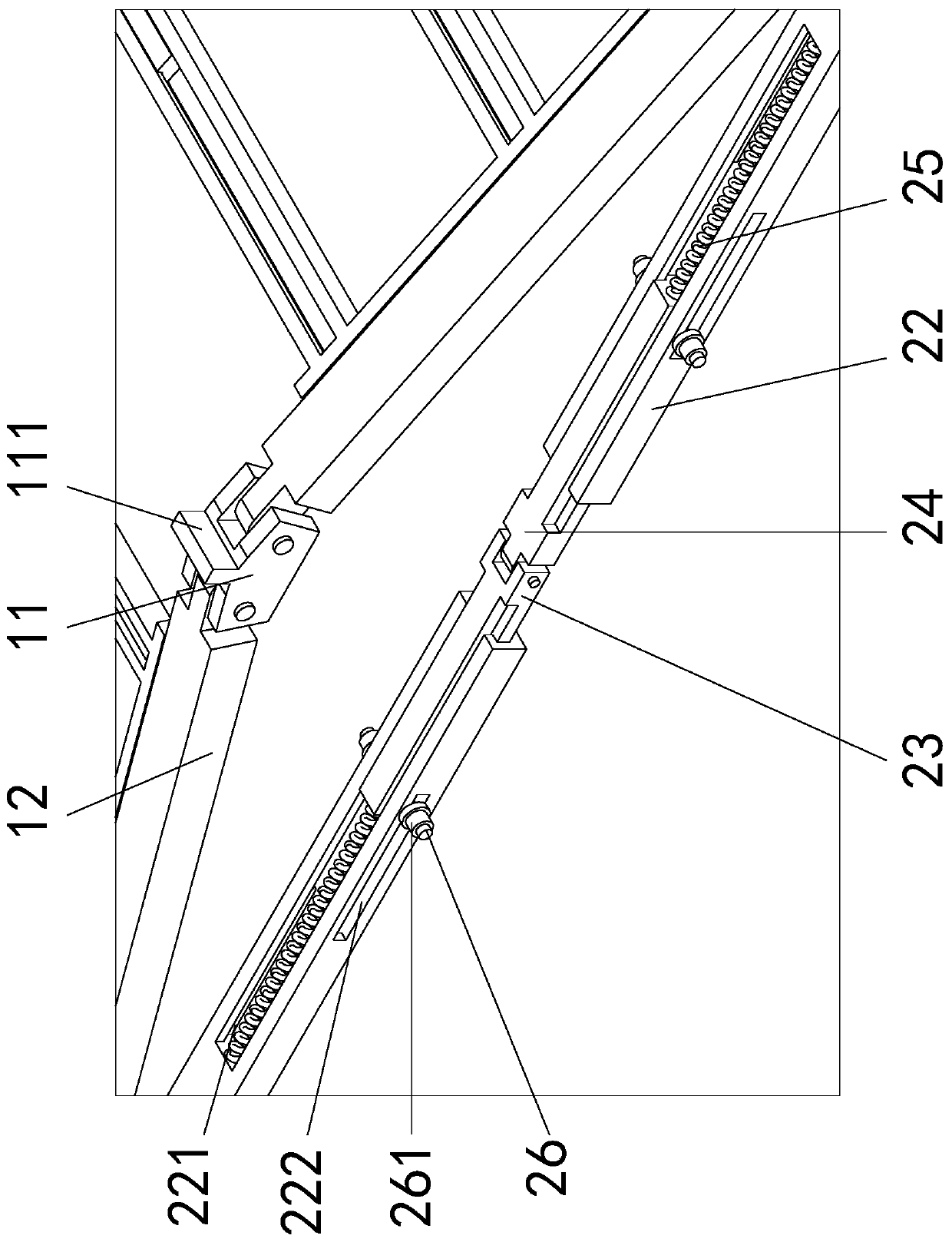

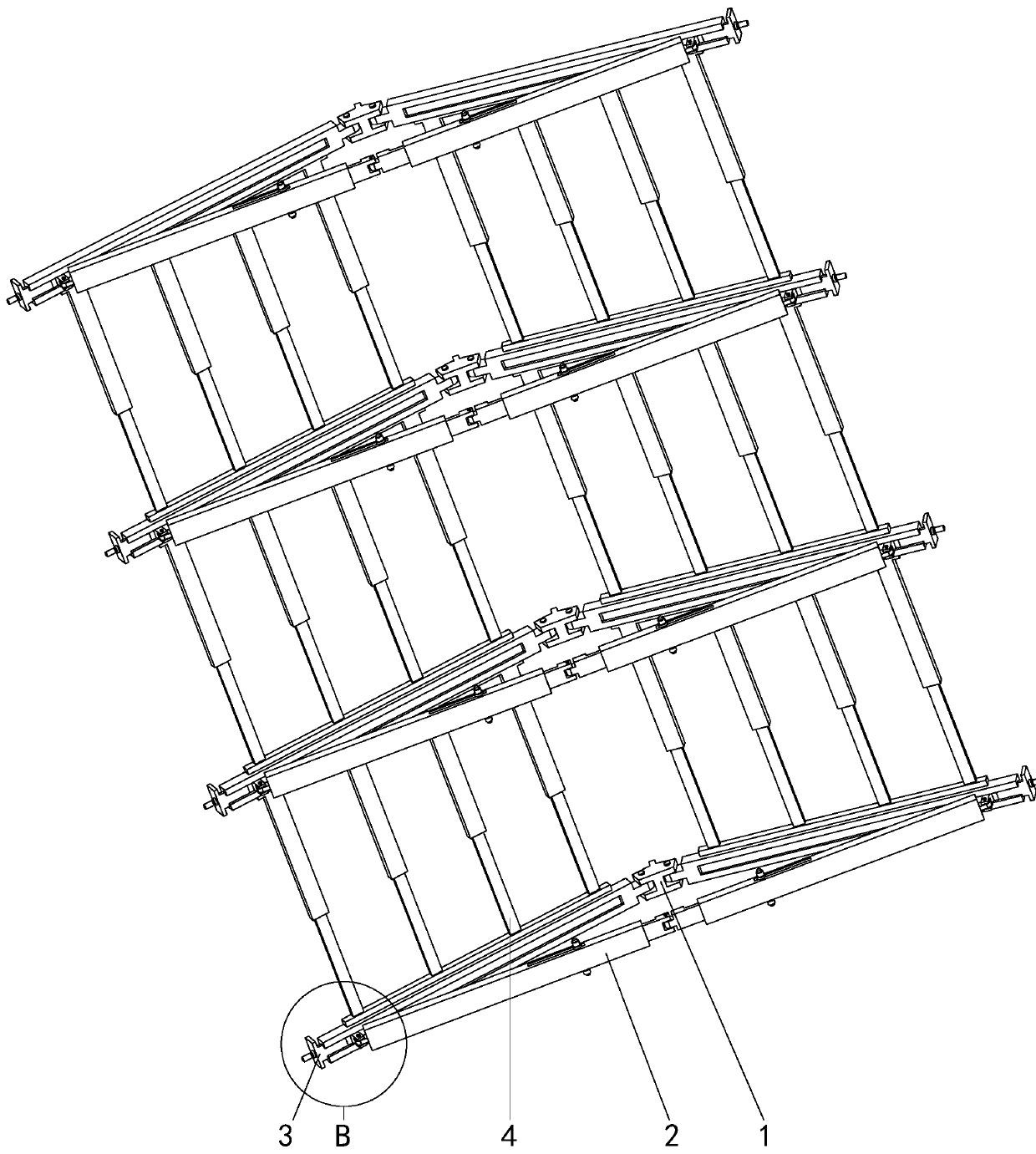

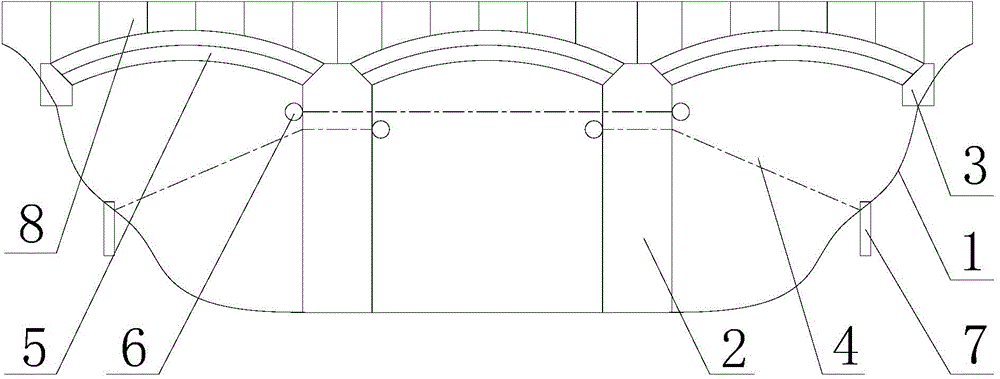

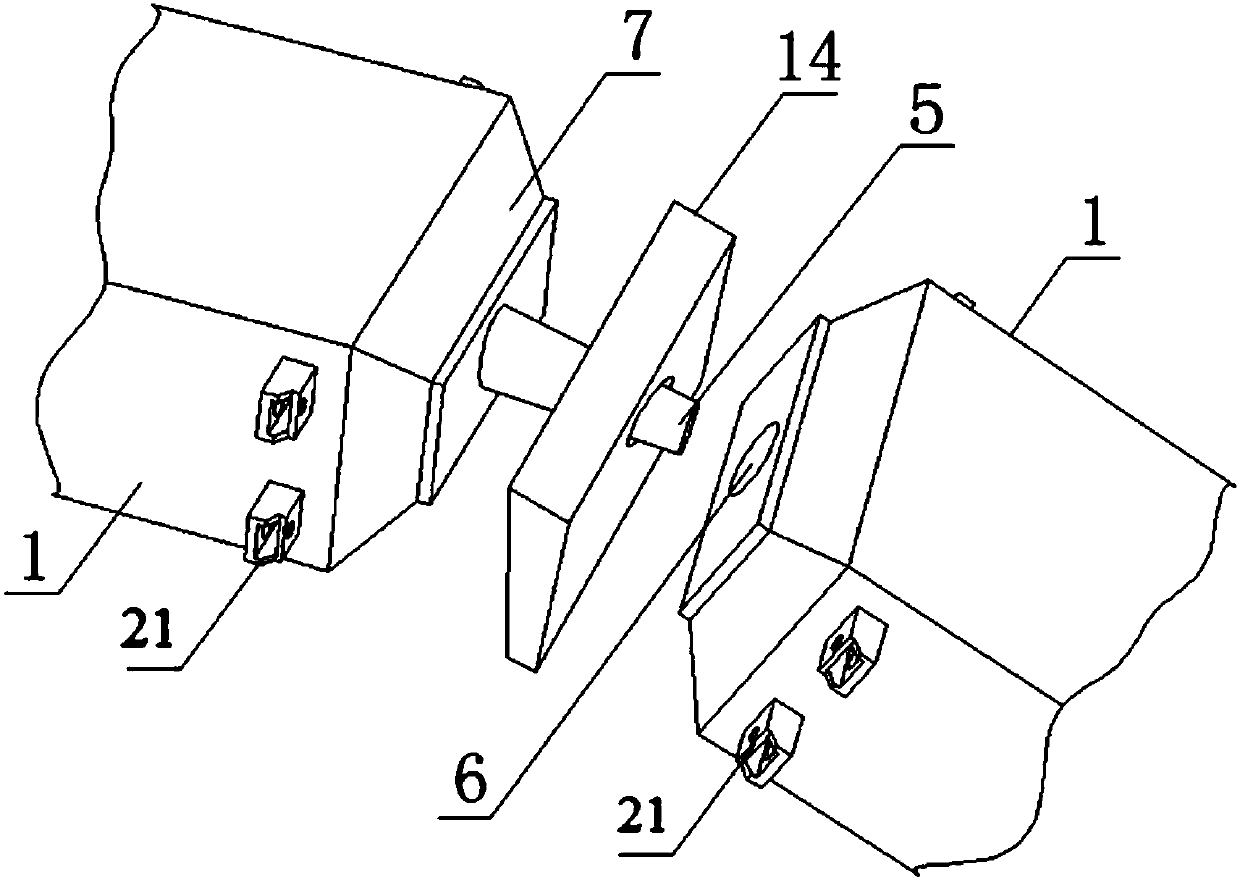

Assembled light steel structure roof

InactiveCN111456247AQuick assemblyQuick dismantlingGirdersJoistsManufacturing engineeringMechanical engineering

The invention relates to an assembled light steel structure roof. The assembled light steel structure roof includes roof beam components, cross beam components, lower baffle components and stringer frame components; the light steel structure roof includes a plurality of the roof beam components arranged in a straight line; two adjacent roof beam components are fixed in series through two stringerframe components; each of the roof beam components is correspondingly arranged with the cross beam component; and each of the roof beam components is arranged with two lower baffle components. The assembled light steel structure roof provided by the invention is assembled by multiple components, which can realize rapid assembly during construction, and can also realize rapid disassembly; the structural characteristics of each component before assembly can be maintained after disassembly; folding structure design can reduce the occupied space and facilitate transfer and transportation; and thesteel structure roof can be assembled again to achieve repeated recycling, which avoids the waste of resources.

Owner:吴传江

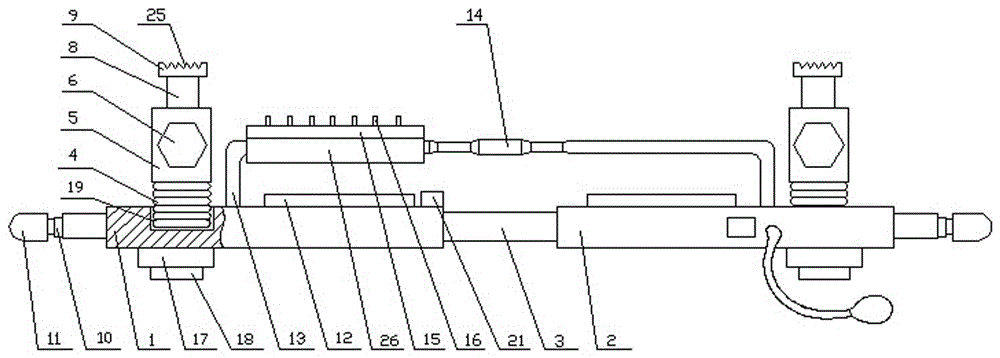

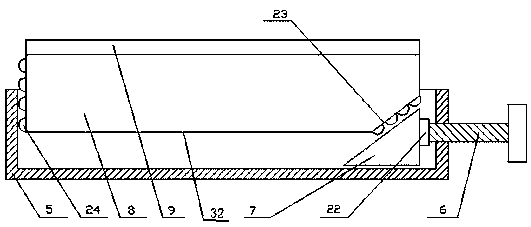

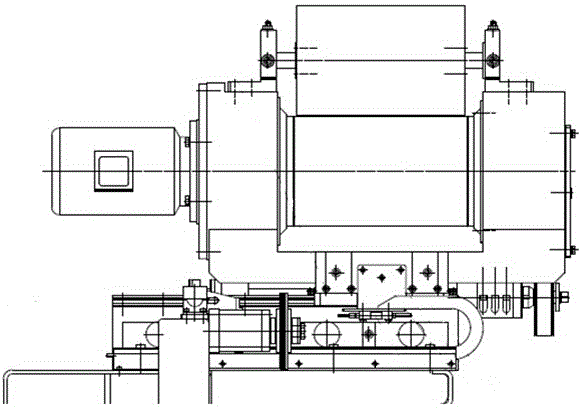

Arc-length-variable wire cutting saw for machining crisp and hard materials

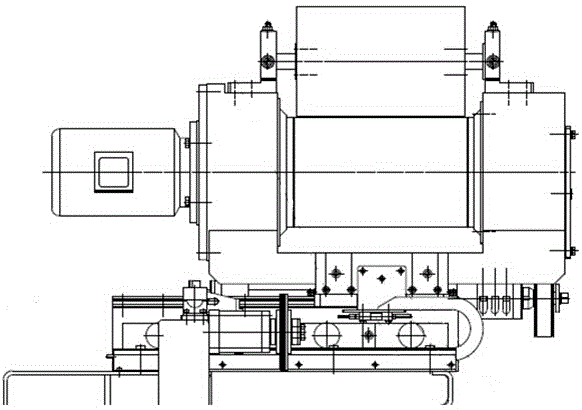

InactiveCN105108921ASmall sawing forceReduce power consumptionWorking accessoriesFine working devicesWire tensionWire cutting

The invention provides an arc-length-variable wire cutting saw for machining crisp and hard materials in the technical field of mechanical manufacturing and applied to extreme machining. The arc-length-variable wire cutting saw comprises a wire guide wheel drive mechanism, a wire cylinder and wire conveying mechanism, a wire tension adjusting and controlling mechanism, a driving and cutting mechanism, a stand column and beam and a workbench. The workbench is installed on a lower beam body of the stand column and beam. The wire cylinder and wire conveying mechanism is arranged on an upper beam body of the stand column and beam. The wire tension adjusting and controlling mechanism and the driving and cutting mechanism are arranged on a stand column of the stand column and beam. The wire guide wheel drive mechanism is fixed to the upper end of the stand column of the stand column and beam. A second lead screw is driven by a synchronous belt to rotate so as to drive a fist sliding base matched with the second lead screw to move up and down along a second guide rail. A first wire guide wheel and an adjusting wheel are fixed to the first sliding base through bearings. By means of the arc-length-variable wire cutting saw, the sawing wire can be much fine, and the saw seam width is lowered; the using rate is increased, and the span of cutting wheels of the wire saw is adjustable; and the wire cutting saw is small in saw shearing force, few in cuttings, low in noise, smooth and orderly in cut face, simple in structure and low in cost.

Owner:SHENYANG LIGONG UNIV

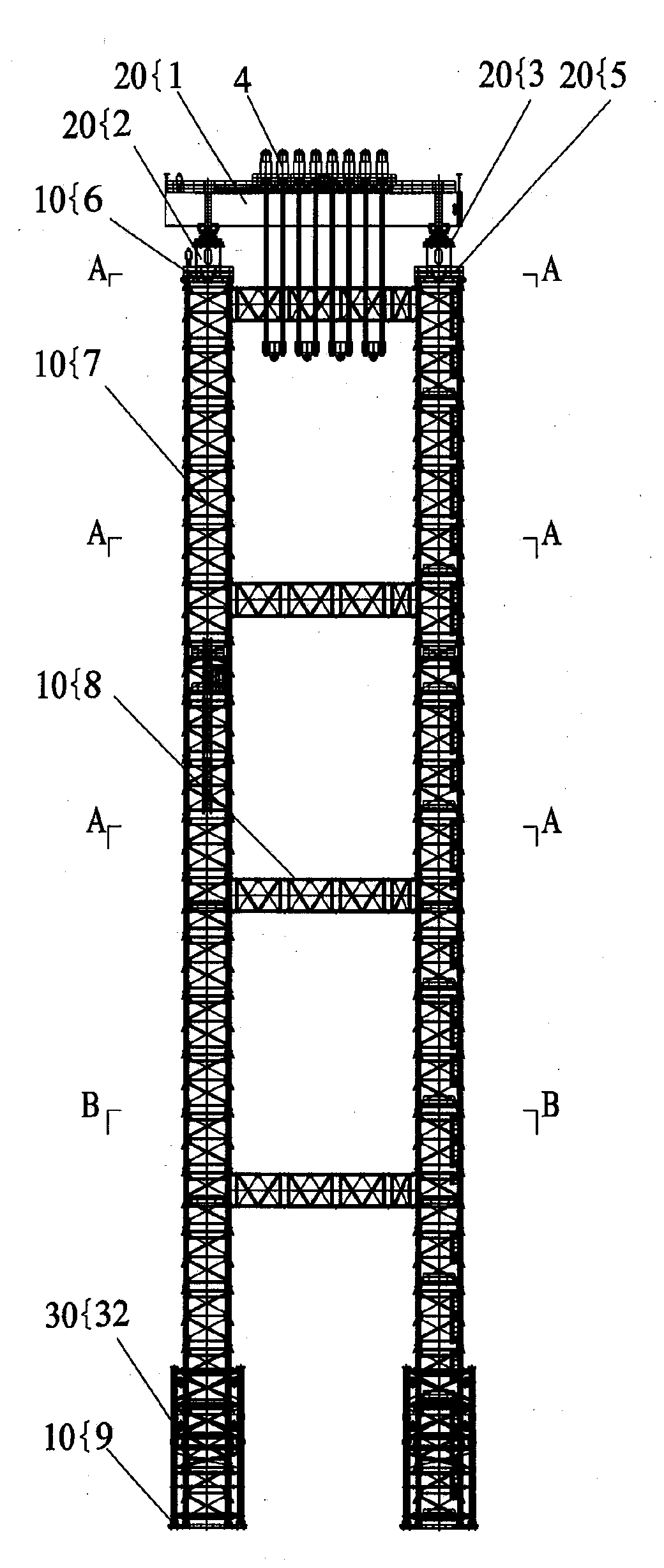

Construction method of reinforced concrete multi-span arch bridge or continuous box structure bridge

ActiveCN104963292ASolve horizontal thrustLengthen the construction sectionBridge erection/assemblyHorizontal forceReinforced concrete

The invention discloses a construction method of a reinforced concrete multi-span arch bridge or a continuous box structure bridge. The method is implemented according to the following steps: step 1) constructing the lower part structure of the arch bridge, wherein the lower part structure comprises a foundation, a middle pier and a bridge abutment; step 2) fixing flexible cables to piers of the arch bridge, fixing ground anchors through the flexible cables, and fixing the ground anchors to a ground to balance the horizontal force borne by the pier; step 3) erecting arch supports on each span of the bridge; step 4) constructing the upper part structure of the arch bridge on the arch supports; and step 5) removing the flexible cables and the arch supports. The construction method is simple in technology, reliable in quality, low in construction cost and rapider in construction speed, and the safety risk is lowered.

Owner:CHONGQING BIAOWANG INTEGRATED HOUSING TECH DEV CO LTD

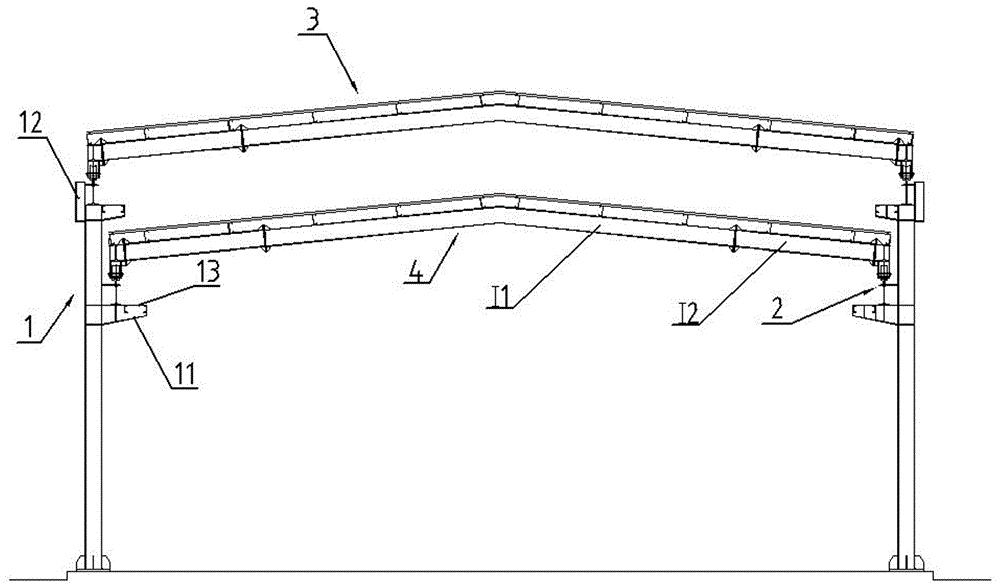

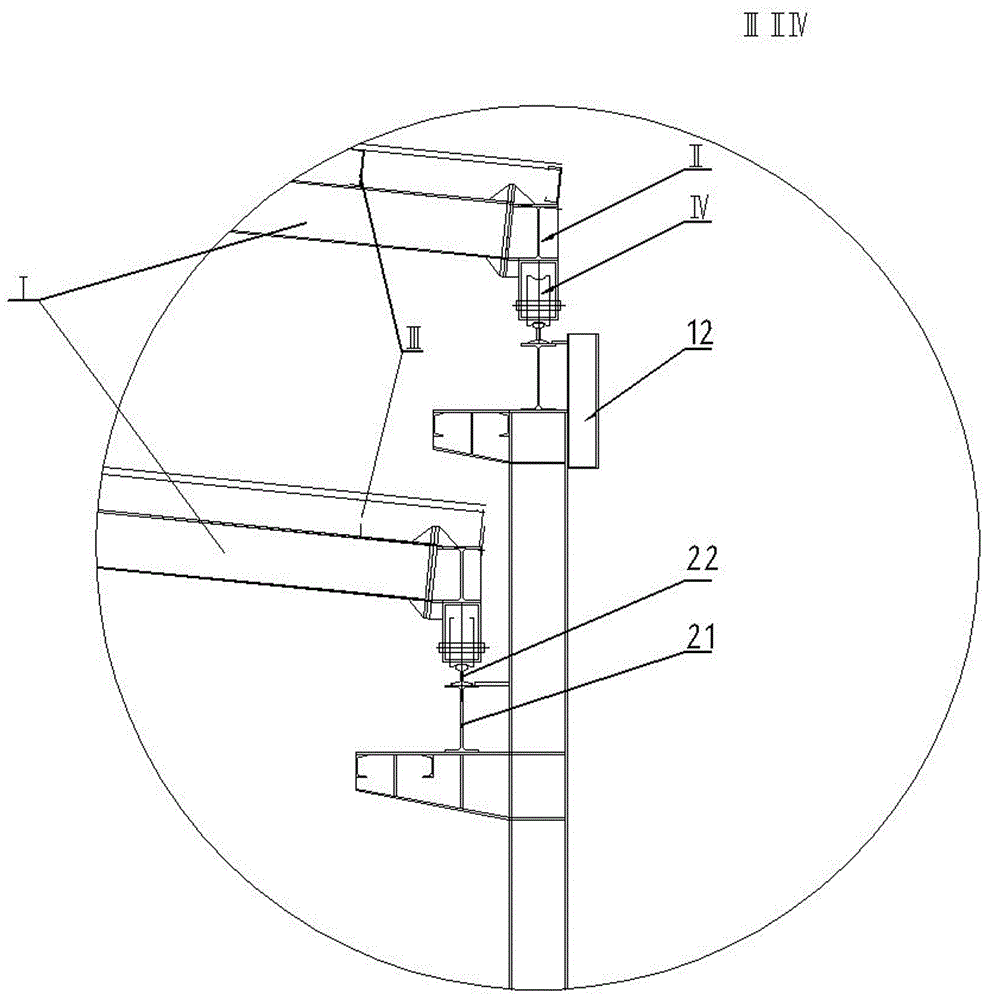

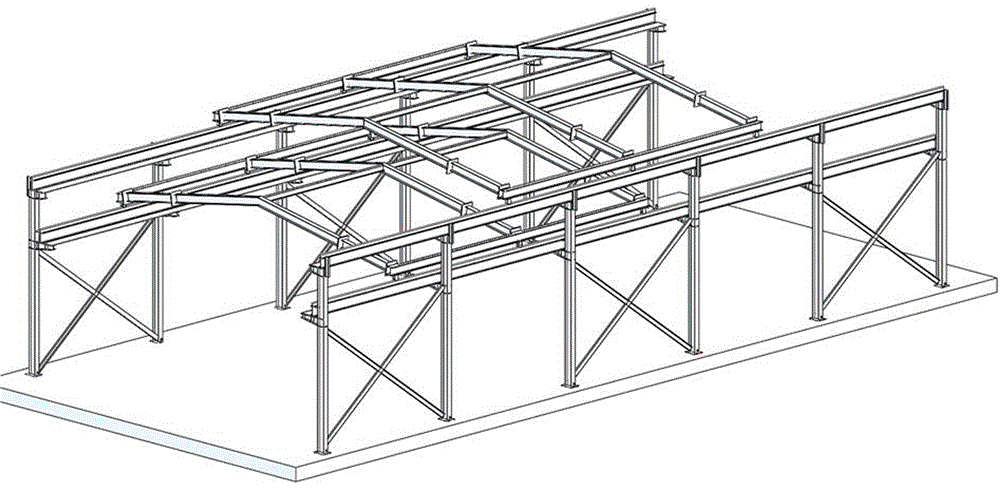

Steel structure flexible shed frame

PendingCN106639106AImprove work efficiencySave manpower and material resourcesBuilding roofsBuilding materialMaterial resources

The invention discloses a steel structure flexible shed frame. The steel structure flexible shed frame comprises stand columns, track longitudinal beams and flexible ceilings. The two rows of stand columns are fixed to a foundation in a symmetry arrangement mode to enable the stability of the whole shed frame to be ensured. The track longitudinal beams are divided into an upper layer and a lower layer which are connected to the upper portions and the top portions of the stand columns, an upper flexible ceiling is connected with the track longitudinal beams on the two sides of the top portions, a lower flexible ceiling is connected with the track longitudinal beams on the two sides of the upper portions, the spans of the two layers of the flexible ceilings both can be adjusted, and the two layers of the flexible ceilings both can move along the corresponding track longitudinal beams. When construction materials in different positions are hoisted, only the flexible ceilings need to be moved to other positions of the track longitudinal beams, the whole shed frame does not need to be moved, and while working efficiency is greatly improved, man power and material resources are saved; the shed frame has universality owing to the fact that the spans of the flexible ceilings are adjustable and can be reused in different construction sites, and waste caused by the fact that the shed frames are not universal among different construction projects is avoided.

Owner:HUNAN WUXIN MACHINERY

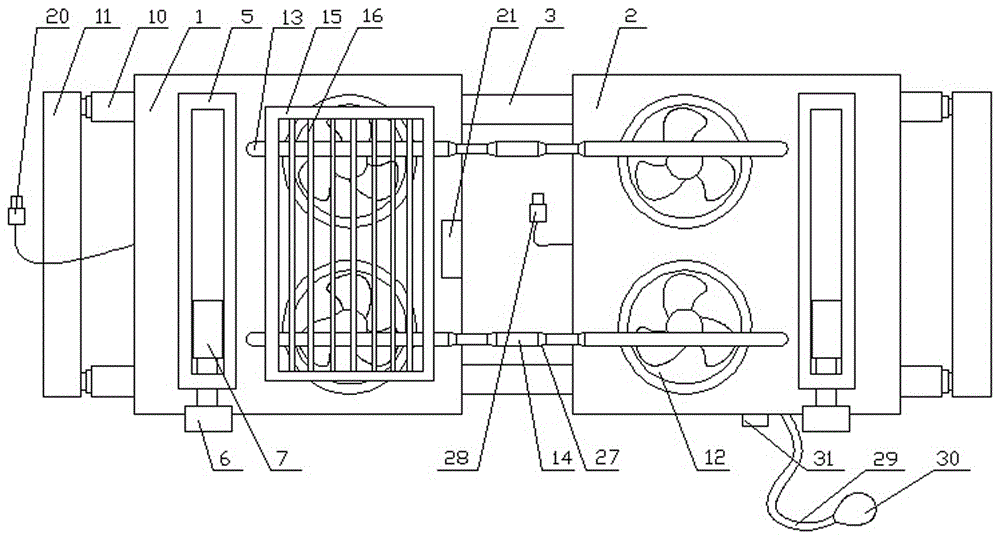

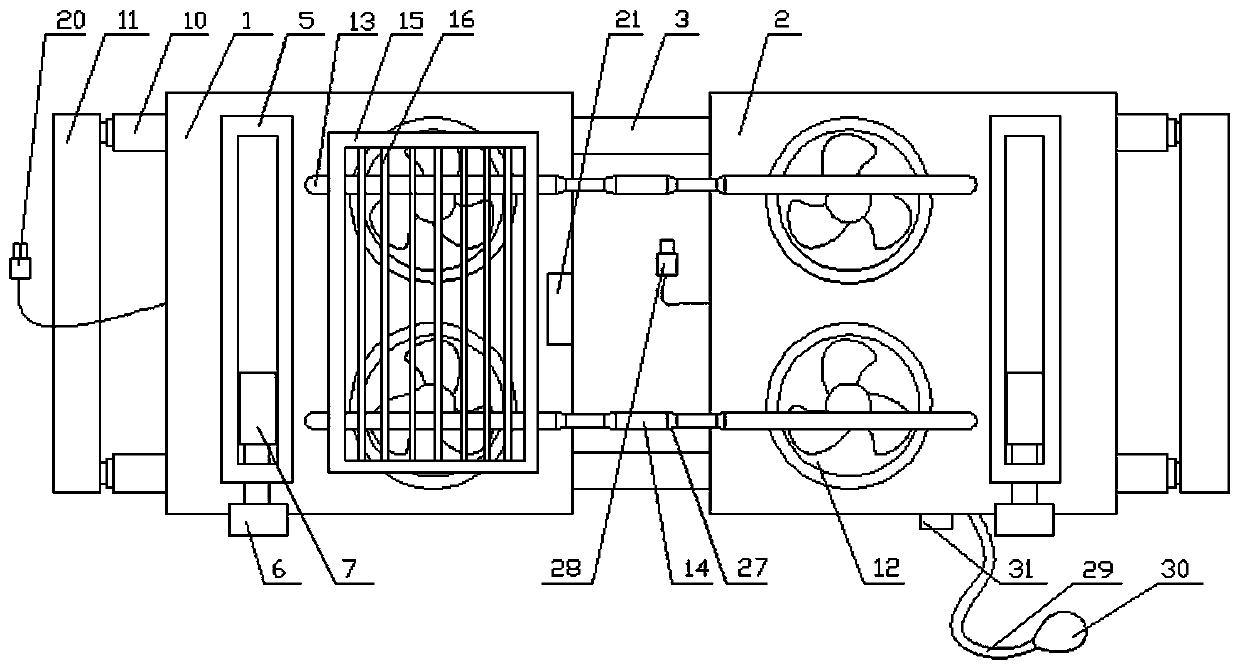

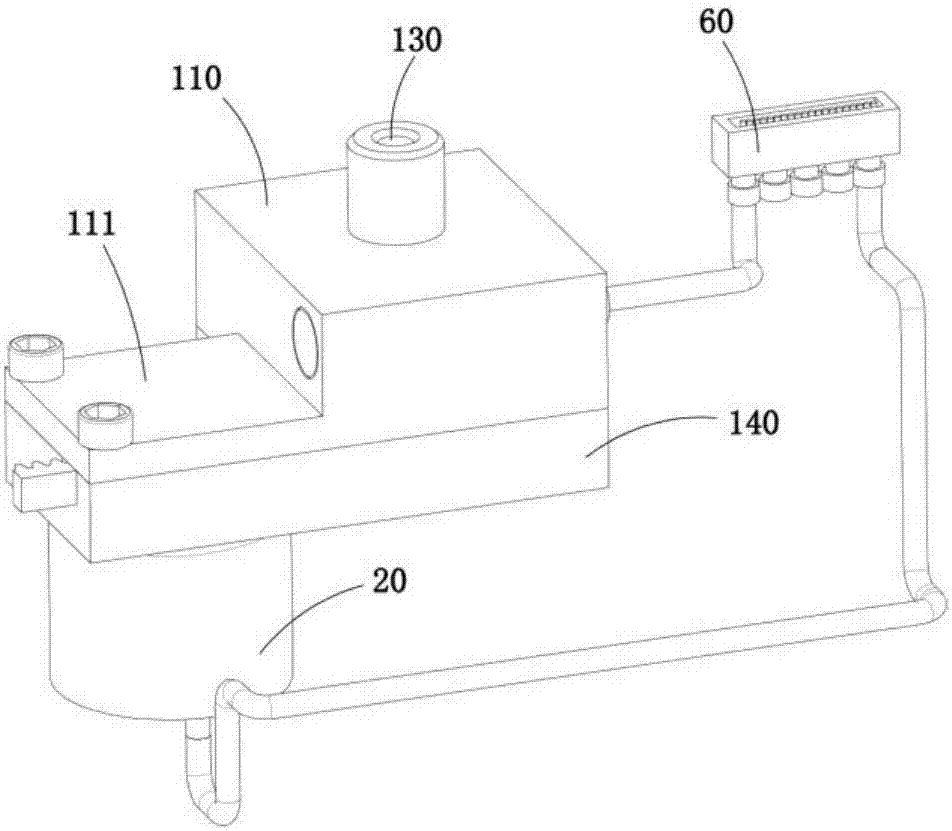

Portable luggable computer heat dissipation device

ActiveCN106325447AIncrease heightAdjustable spanDigital data processing detailsSoftware engineeringRefrigeration

The invention discloses a portable luggable computer heat dissipation device which comprises a left base and a right base. A group of damping springs is arranged on the left base and the right base respectively, the upper ends of the damping springs are matched with lifting sleeves, one end of each lifting sleeve is in screwed connection with a lifting bolt, the end of each lifting bolt is rotatably matched with a lifting push block arranged inside the corresponding lifting sleeve, the lifting push blocks are matched with lifting frames arranged inside the lifting sleeves, a group of cooling fans and carriages is arranged on the left base and the right base respectively, the carriage on the left base is connected with the carriage on the right base through a carriage telescoping rod, refrigeration frames penetrate into the carriages, and a group of semiconductor refrigerating sheets are arranged on the refrigeration frames. The portable luggable computer heat dissipation device is stable to place, has the characteristic of stretchable extension, is wide in applicability, can provide good bottom ventilation conditions for a luggable computer, further has a local refrigeration role and has pertinence in heat dissipation.

Owner:南通北外滩建设工程有限公司

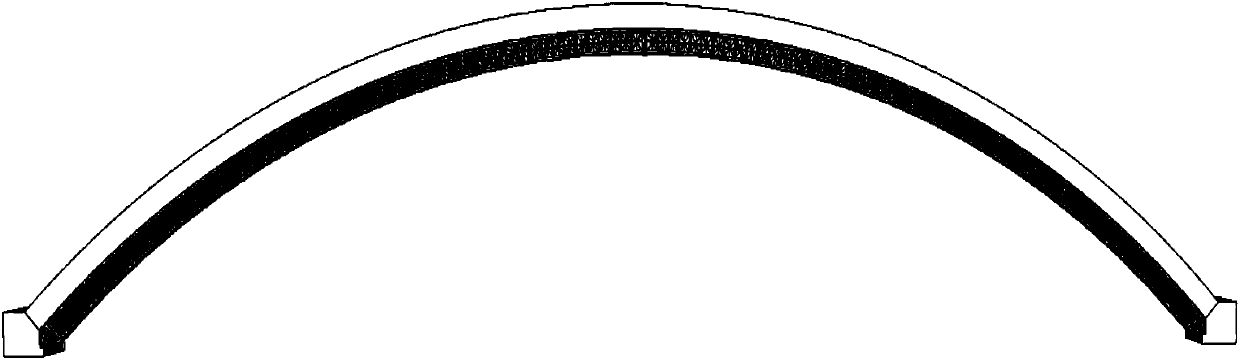

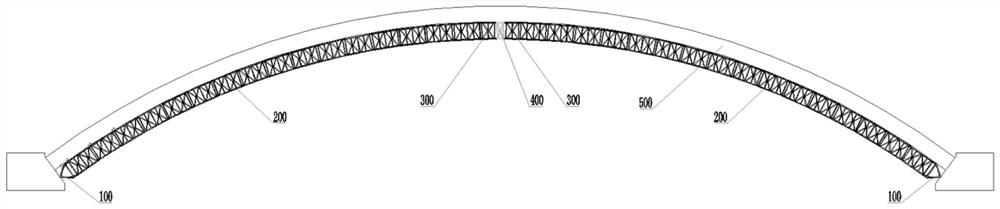

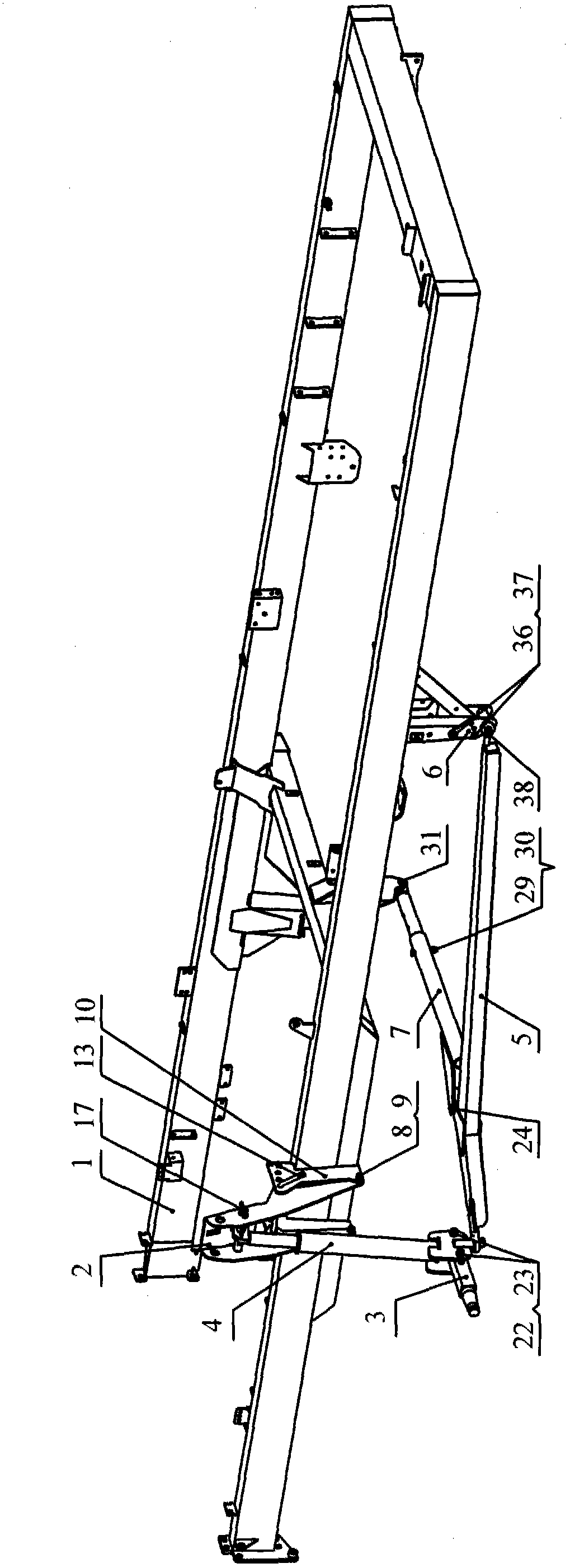

Large-span steel arch frame

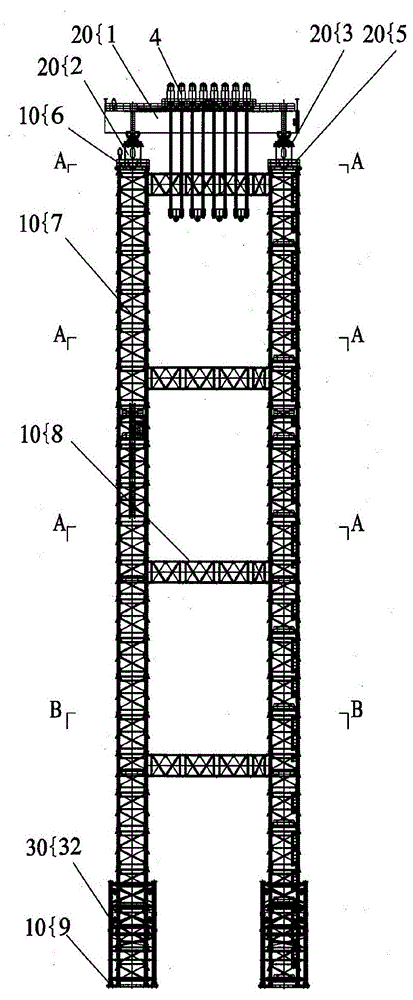

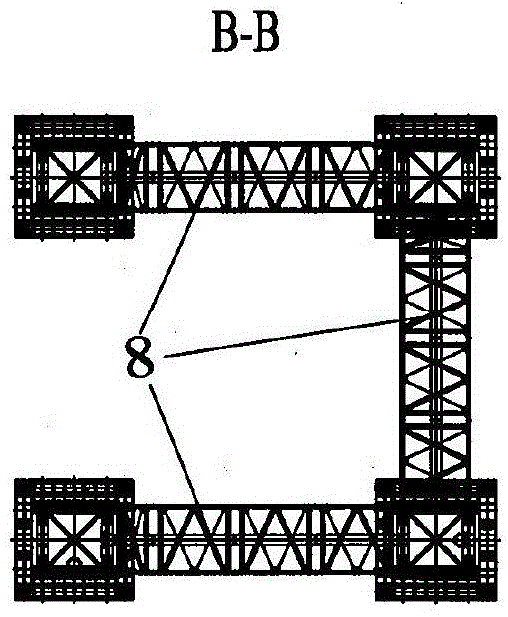

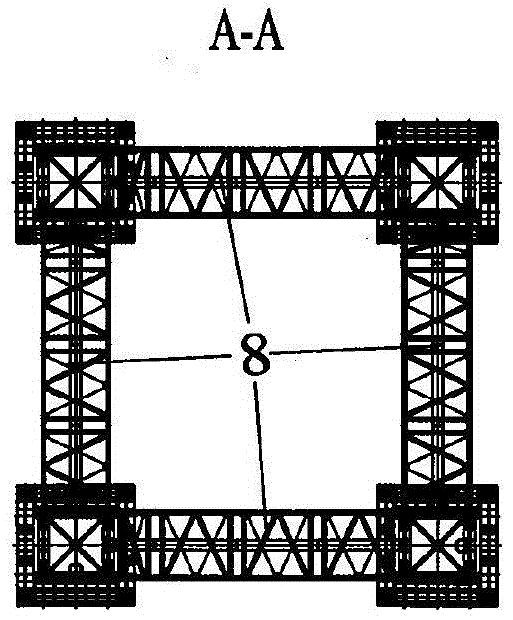

PendingCN110106773AHigh adjustment accuracyImprove visibilityBridge erection/assemblyArch-type bridgeReinforced concreteArch bridge

The invention provides a large-span steel arch frame. The large-span steel arch frame is mainly composed of arch foot segments, standard segments, adjusting segments, closing segments and closing devices in an assembled mode, except the closing devices, lower chords of the adjacent segments are in hinged connection through penetrating pins, and upper chords of the adjacent segments are in opposite-pulling connection through bolts on the multiple side faces of chord members, so that the arch frame is formed; and wedge blocks are arranged between the transverse end faces of the upper chords of the adjacent segments, and the wedge blocks are axially and radially limited between the transverse end faces of the adjacent segments. The large-span steel arch frame is adjustable in rise span ratio,adjustable in span and especially suitable for construction of a main arch ring of a cast-in-place reinforced concrete arch bridge with the span being greater than 150 meters; and the rise span ratioand the span of the large-span steel arch frame are adjusted ingeniously, the force transfer effect is good, stability is good, and the force transfer effect is quite excellent.

Owner:CHONGQING BIAOWANG MACHINERY EQUIP CO LTD

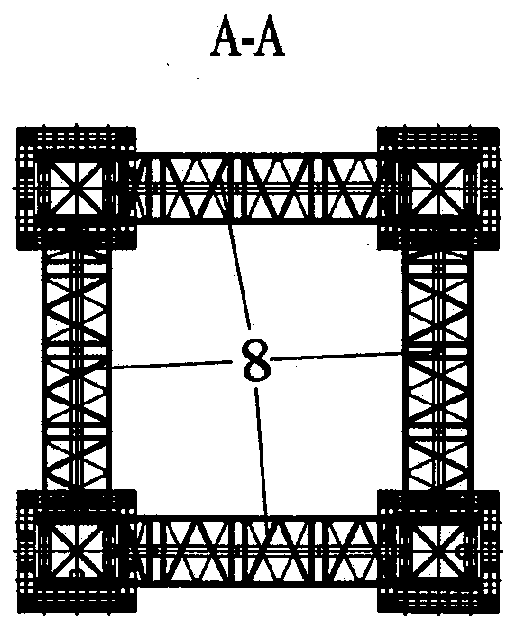

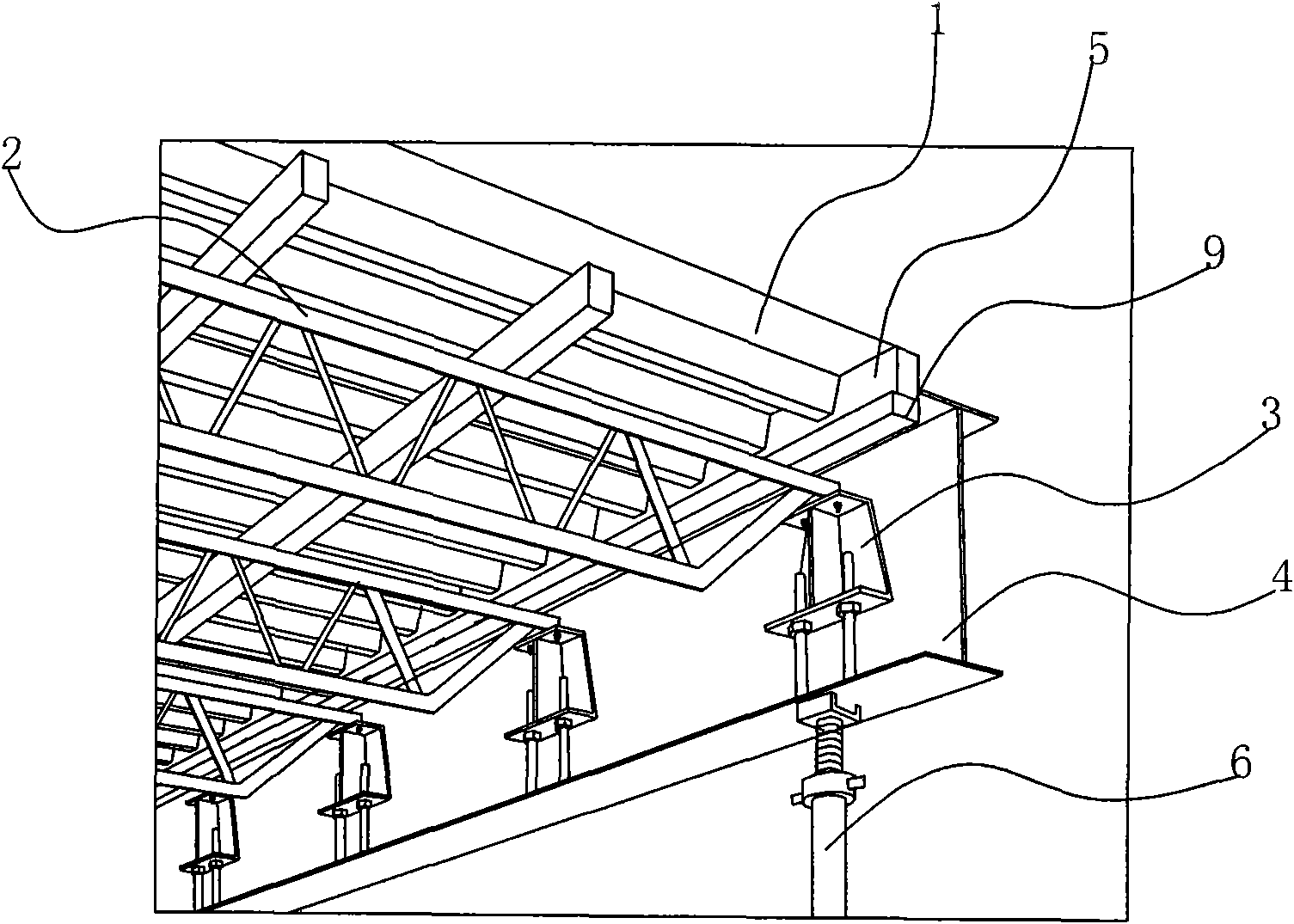

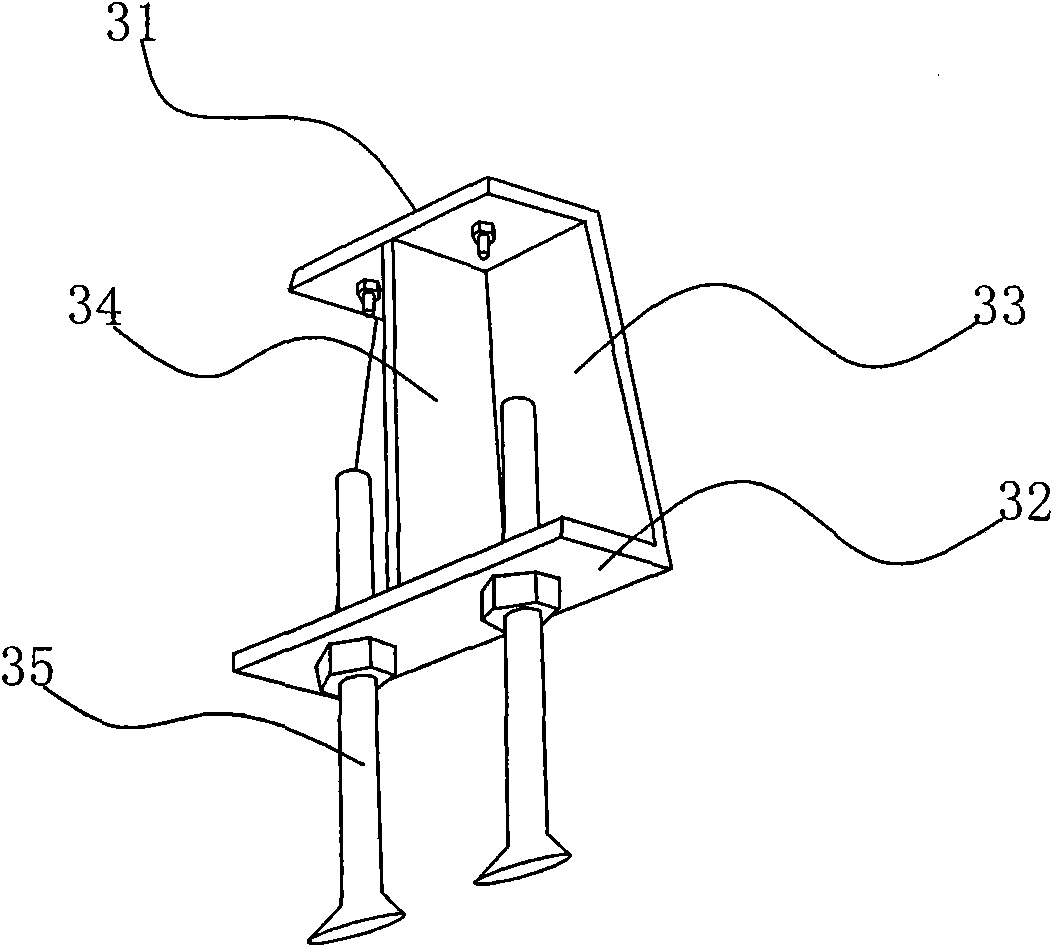

Formwork support system for cast-in-place slabs with large-span steel beams

ActiveCN102418416BImprove applicabilityLow costForms/shuttering/falseworksFloor slabStructural engineering

The invention discloses a long-slab-span steel beam cast-in-situ floor formwork system, which comprises a floor template, an adjustable truss and an adjustable placement support seat for supporting the adjustable truss, wherein a grille is laid on the adjustable truss; the floor template is laid on the grille; the adjustable placement support seat is arranged on a lower flange of a transverse H-shaped steel beam; and the adjustable truss is a telescopic combined truss and is connected with the upper end of the adjustable placement support seat. Compared with the conventional normal truss formwork system, the long-slab-span steel beam cast-in-situ floor formwork system provided according to the invention has the advantages of adjustable span, adjustable height and suitability for different beam heights; the adaptability of the truss is greatly improved; and the formwork cost is greatly lowered.

Owner:杨峰

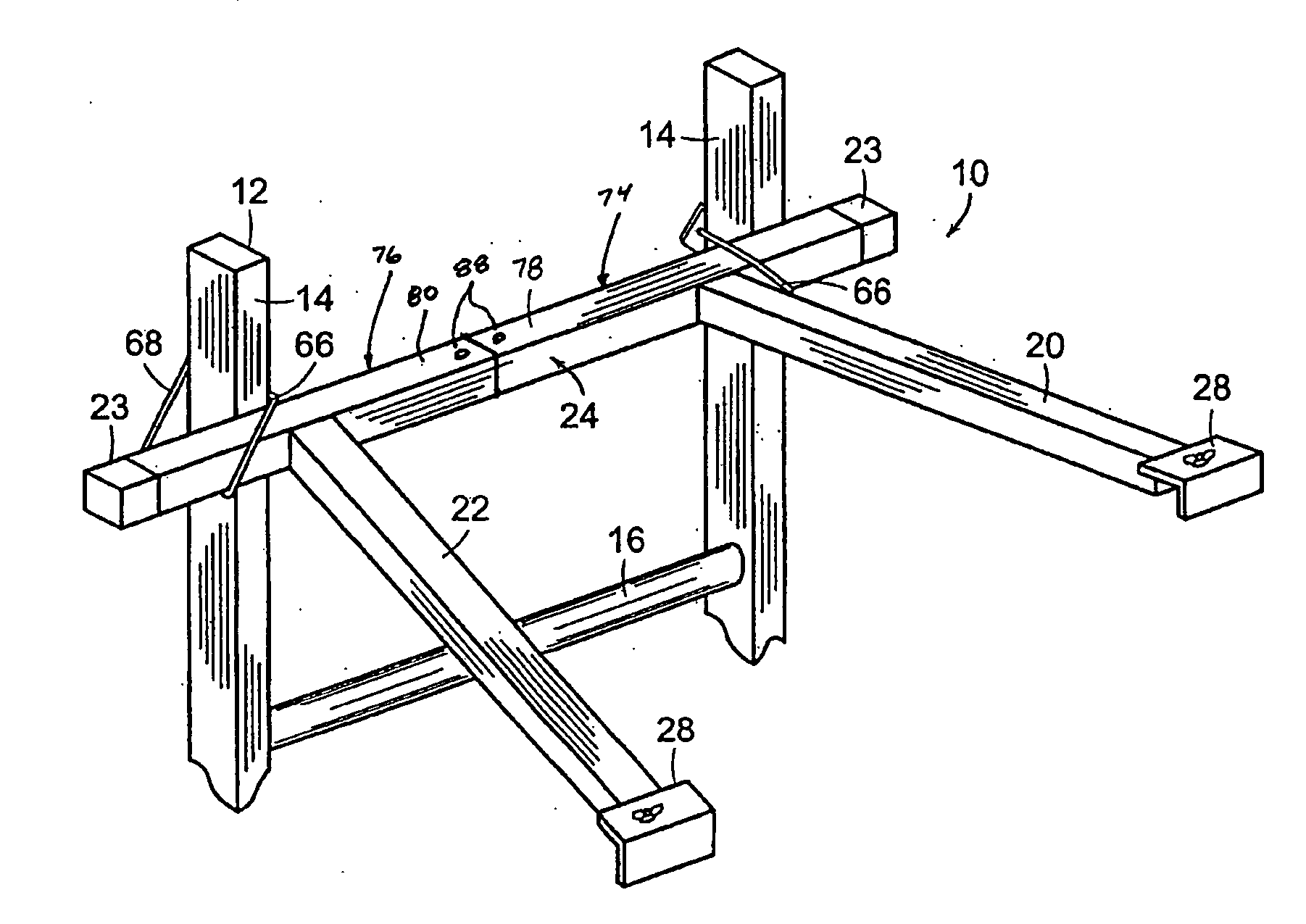

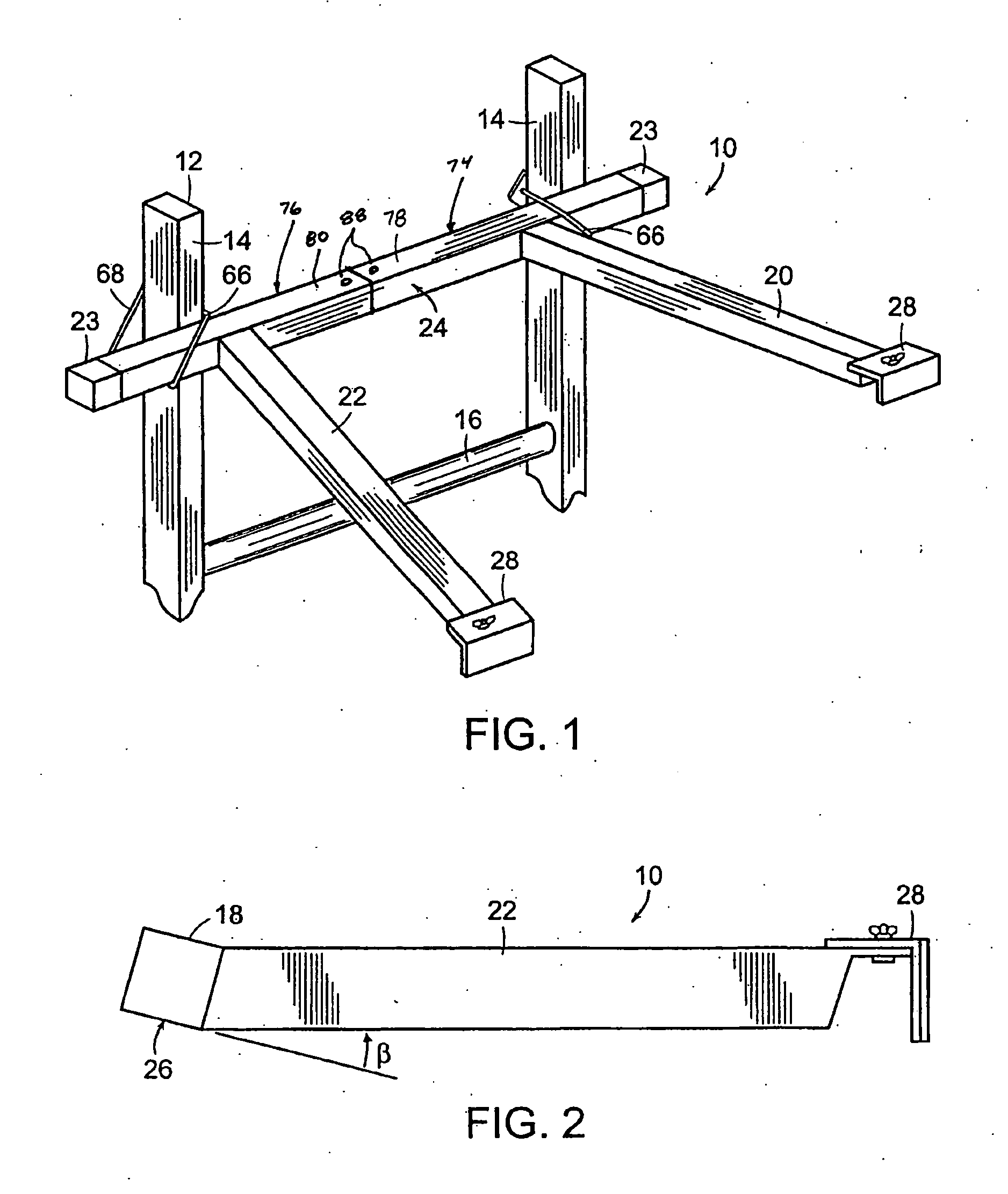

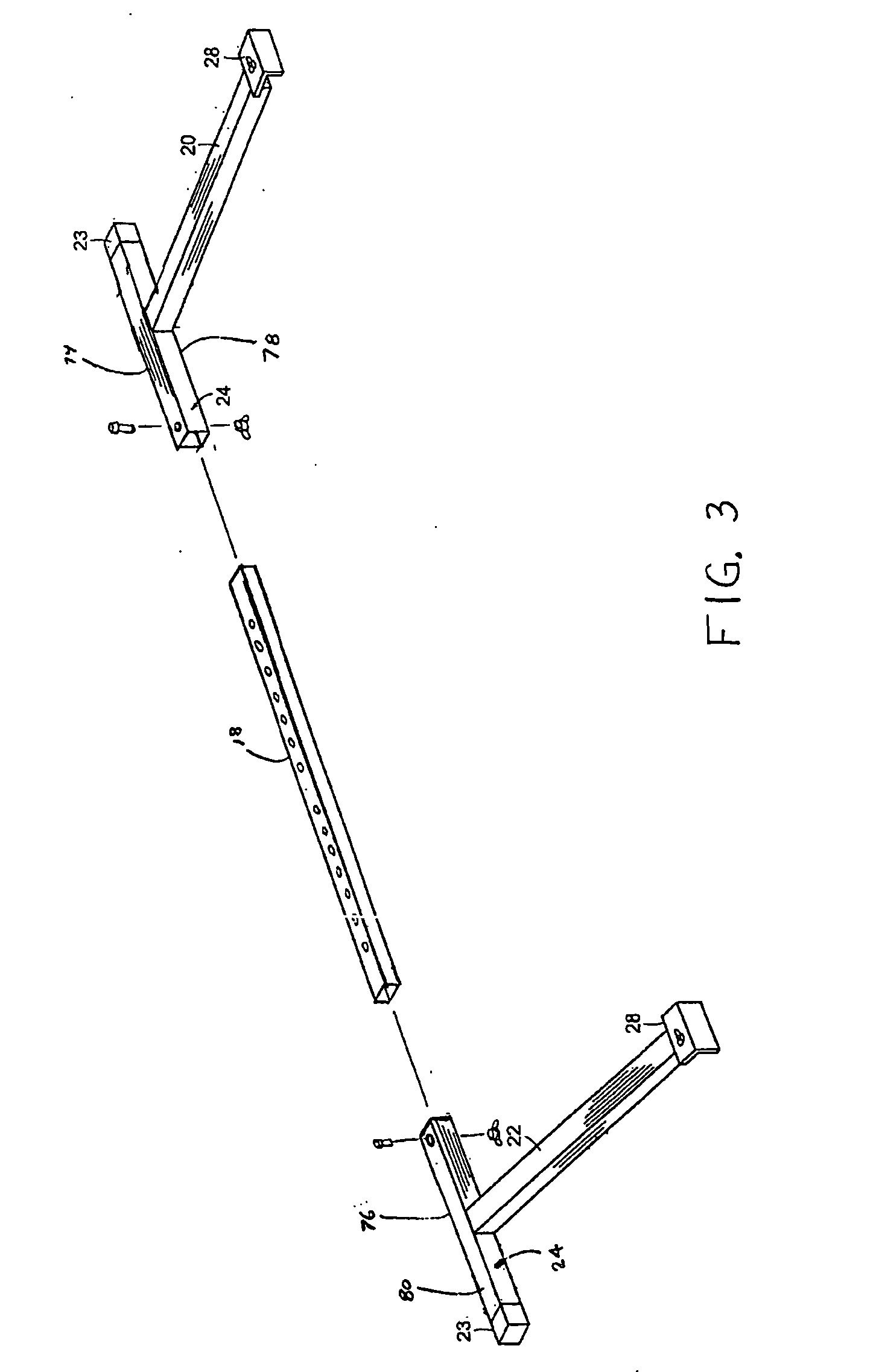

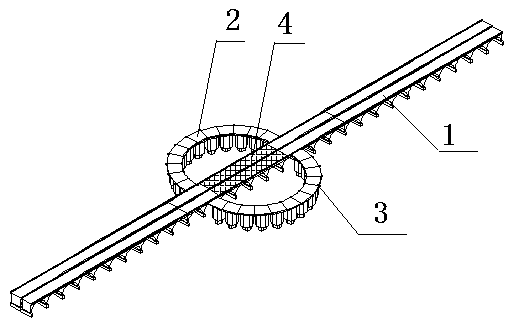

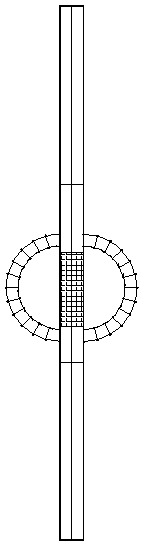

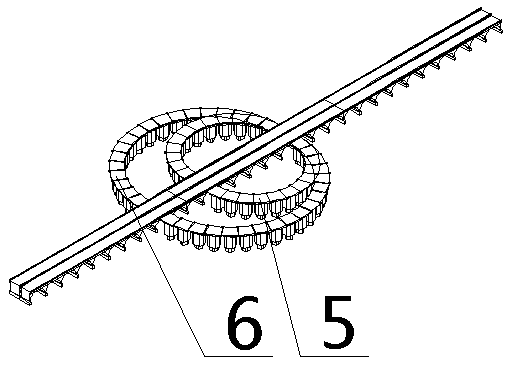

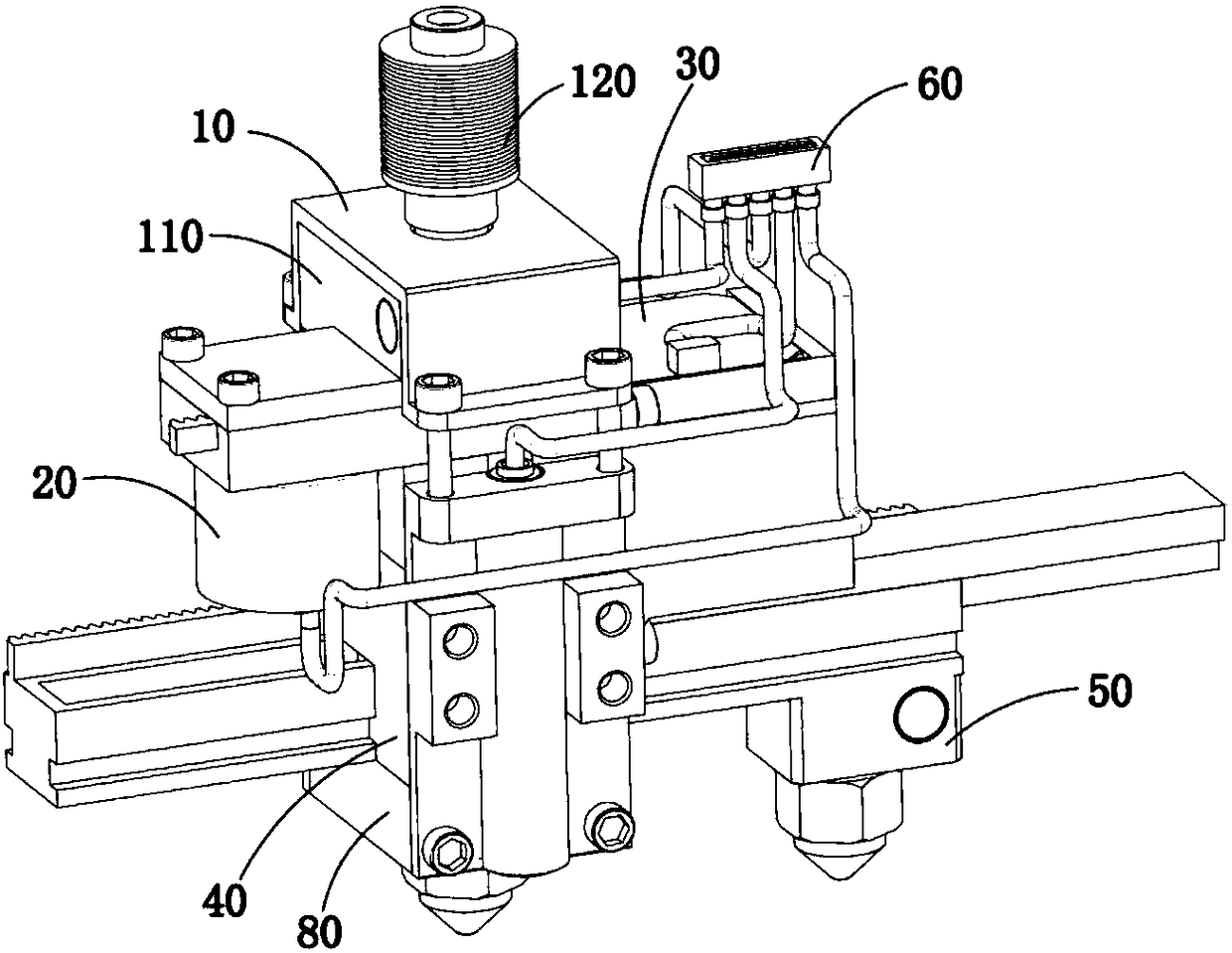

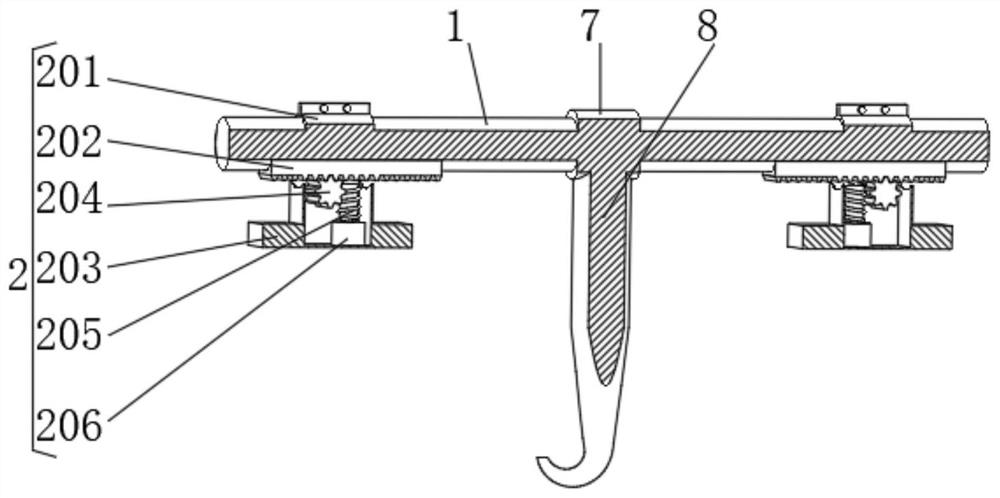

Ladder stand-off

A ladder stand-off includes an extension beam and first and second stand-off sections slidingly mounted on the extension beam, so as to provide an adjustable span. Each stand-off section includes a support beam and an arm fixedly connected to the first support beam. A contact element is pivotally contacted to the outer end of each arm, allowing the device to be used with flat, curved and corner surfaces. The two arms preferably extend in an outward direction so as to be angularly divergent with respect to each other. The device can also be implemented as a ladder stand-off kit having multiple extension beams of different lengths that can be used interchangeably with the two ladder stand-off sections. In this case, the desired extension beam would be assembled with the first and second stand-off sections to form a ladder stand-off.

Owner:UNDERHILL PHILIP ORLANDO +2

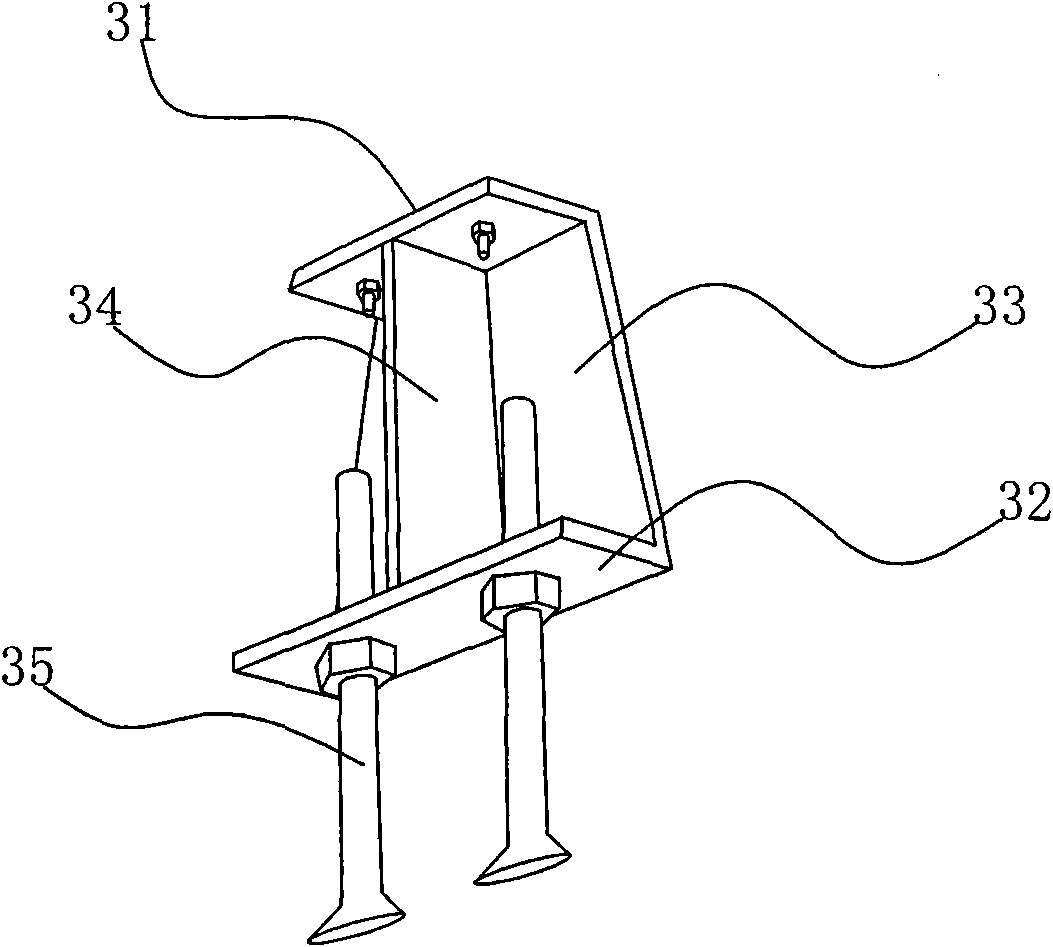

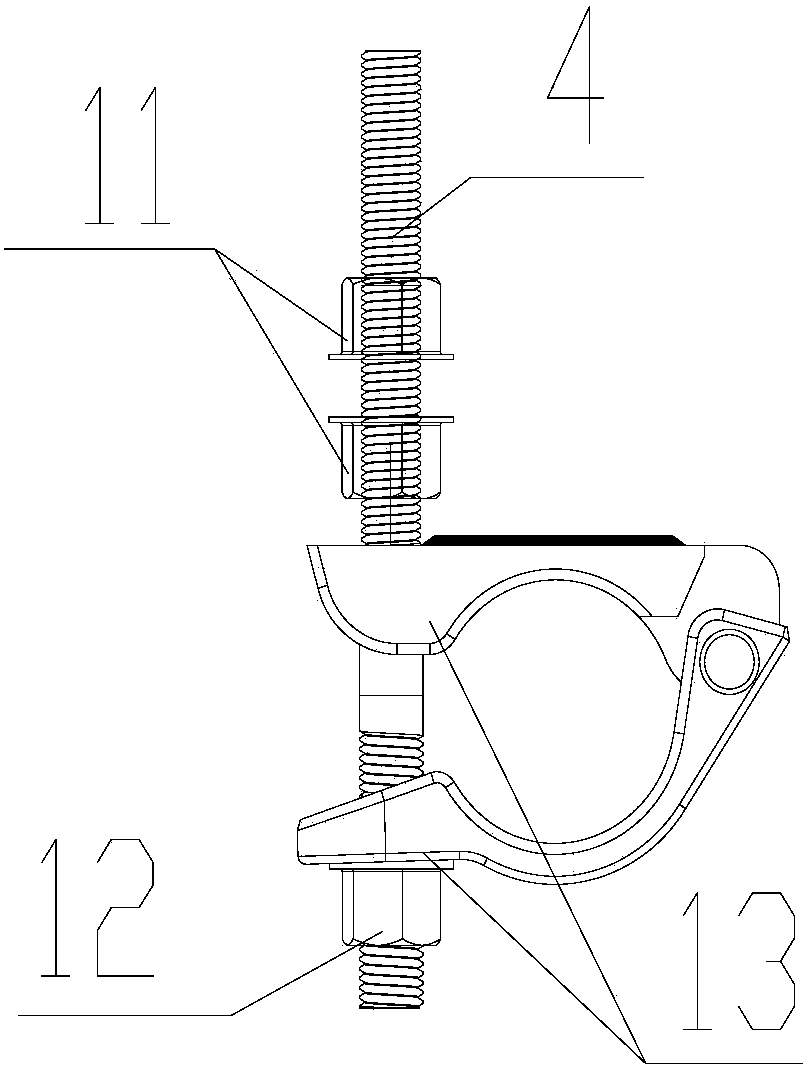

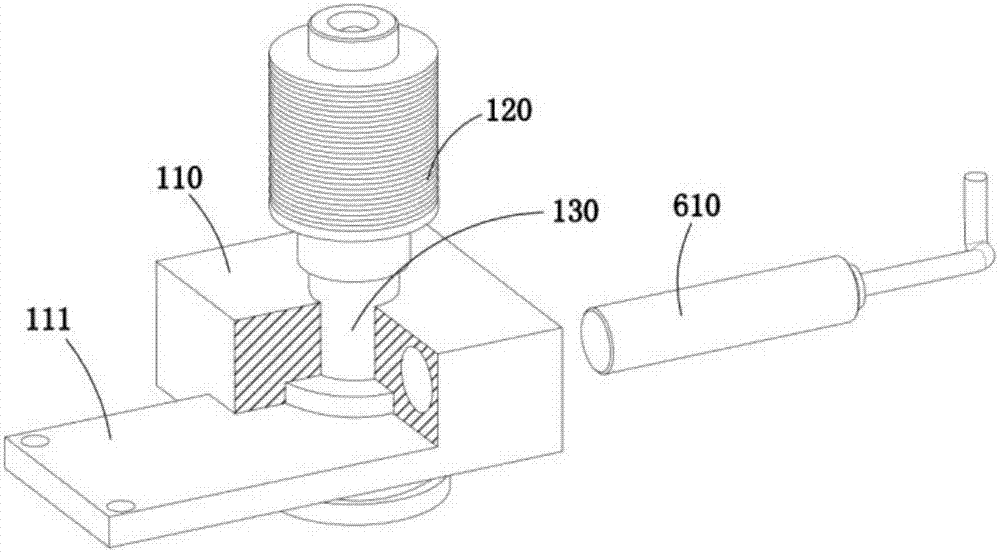

Box opening tool for gear box

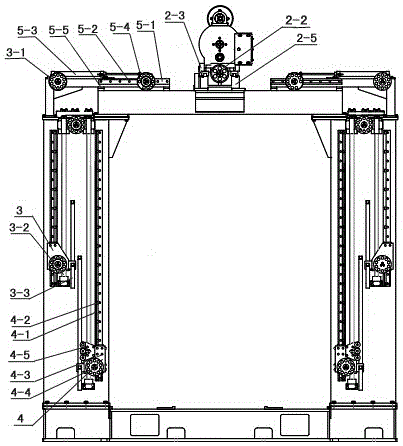

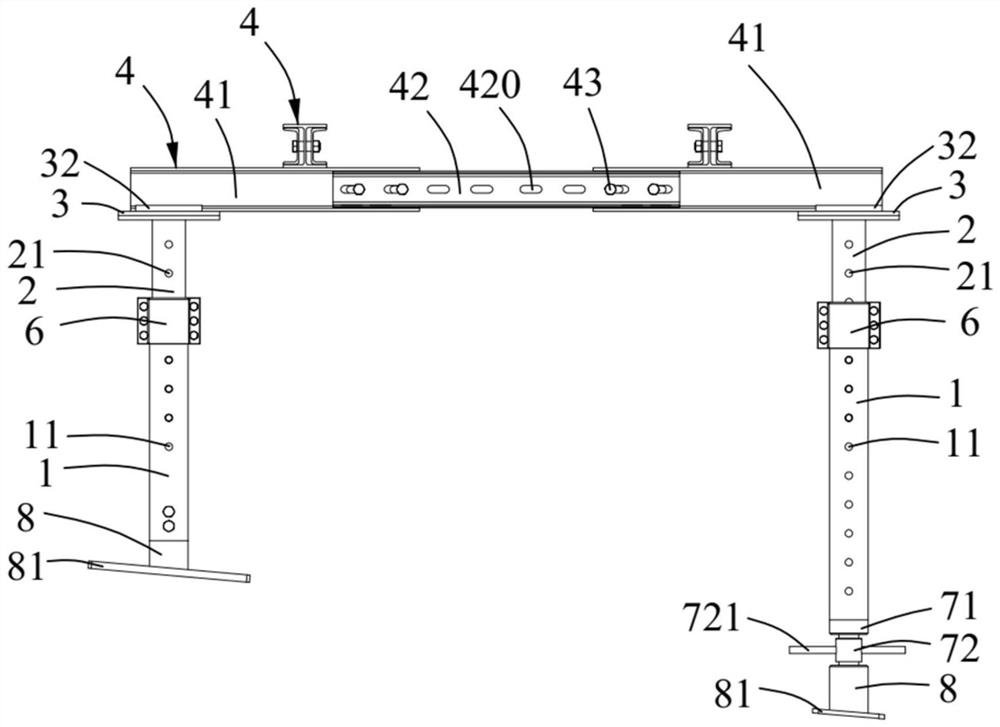

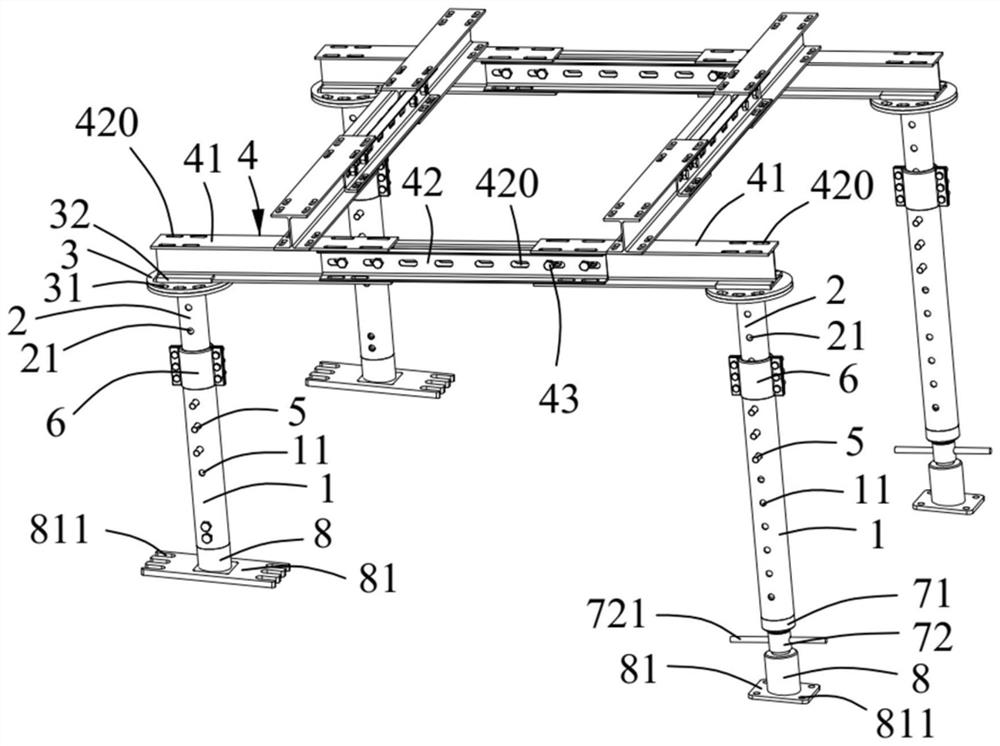

The invention belongs to the field of wind power generation equipment, and discloses a box opening tool for a gear box. The box opening tool for the gear box comprises at least two stand column assemblies, rotating pieces and a supporting beam; each stand column assembly comprises a first rod and a second rod, the bottom end of each first rod is fixedly arranged, and each second rod is arranged on the corresponding first rod in a sliding mode; the rotating pieces are rotatably arranged at the top ends of the second rods, the length of the supporting beam is adjustable, and the ends of the supporting beam are connected to the corresponding rotating pieces, so that the supporting beams are connected with the at least two stand column assemblies to jointly define a portal frame structure; the portal frame structure defined by the stand column assemblies, the rotating pieces and the supporting beam is high in bearing capacity, simple in structure and easy to disassemble and assemble; and the first rods are in sliding fit with the second rods, the supporting beam is rotationally connected with the stand column assemblies through the rotating pieces, the length of the supporting beam is adjustable, therefore, the height, span and installation position of the box opening tool of the gear box can be adjusted according to different installation working conditions, and universality is improved.

Owner:NANJING HIGH SPEED GEAR MFG

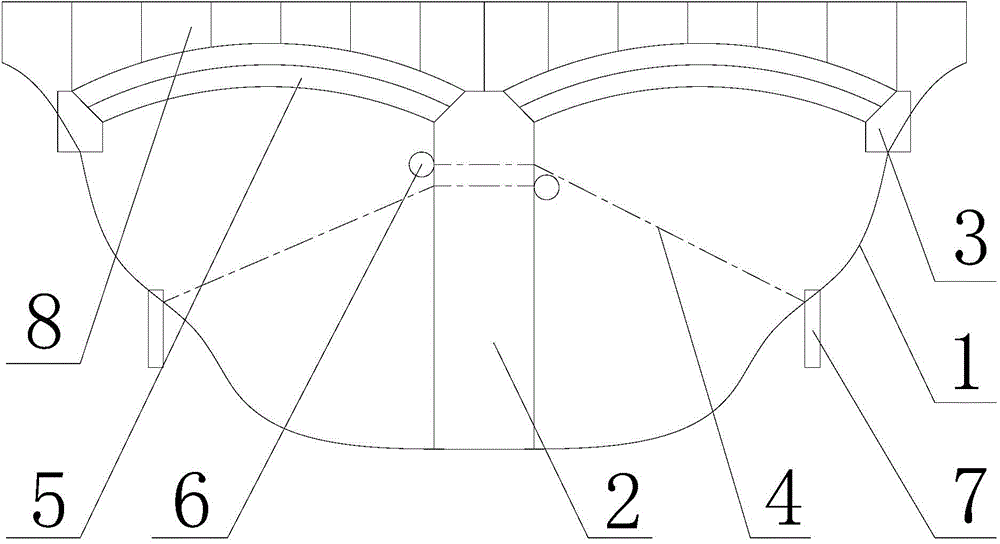

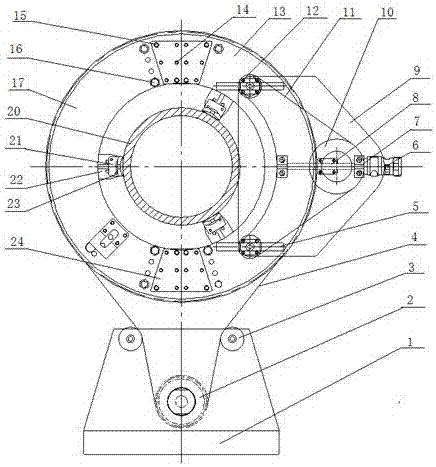

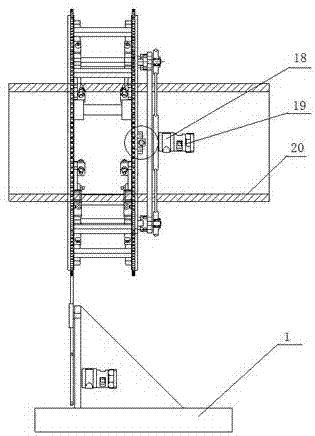

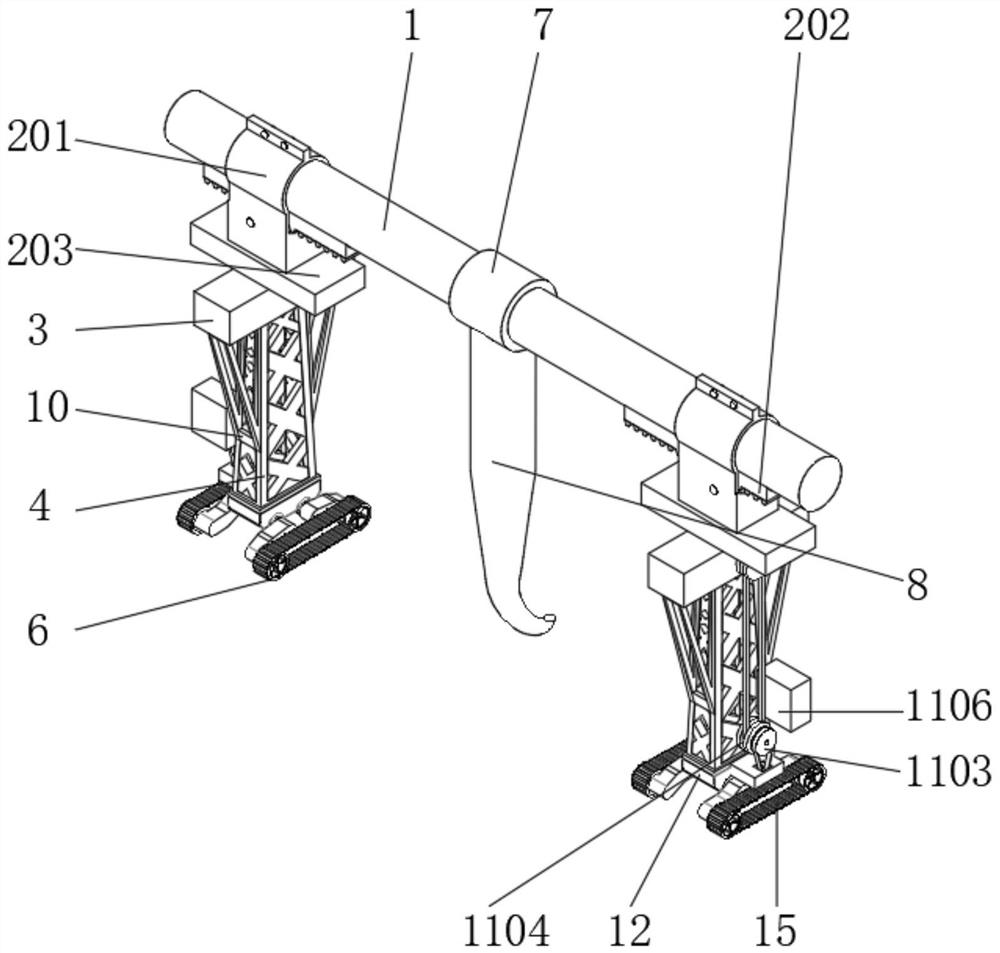

Tubular product rope saw ultrasonic cutting equipment

InactiveCN107042463ALow costAdjustable spanGrinding carriagesGrinding drivesEnvironmental noiseMotor drive

A pipe wire saw ultrasonic cutting equipment, including a base, a turntable drive motor and a sprocket, a slide table guide rail pair, a slide table drive motor, a slide table screw thread pair, a wire saw drive wheel, a wire saw, a cutting guide wheel, a right Semicircular sprocket disc, left semicircular sprocket disc, torsional vibration transducer, wire saw drive motor, etc. The right semicircular sprocket disc and left semicircular sprocket disc are installed on the sprocket disc plate by positioning pins and connecting bolts , and is fixed by the positioning connecting rod to form a complete turntable. Six mobile positioning indenter bases are respectively fixed on the right semicircular sprocket disc and left semicircular sprocket disc according to a 120-degree distribution, and are installed on the mobile positioning indenter seat on the mobile positioning The moving positioning indenter is guided and moved on the indenter seat and fixed by adjusting bolts, and the moving positioning indenter is in contact with the outer circular surface of the workpiece. The saw wire of the invention can be made very thin, the width of the saw seam is reduced, the yield of the material is increased, the span of the cutting wheel of the wire saw is adjustable, the power consumption is low, the noise is low, and the noise is low, and the invention is applied in the technical field of pipe machining.

Owner:AVIC SAC COMML AIRCRAFT

Compensating pontoon device for bridge body maintenance process

InactiveCN108867324BHeight adjustableAdjustable spanBridge erection/assemblyFloating bridgesArchitectural engineeringBridge deck

The invention discloses a compensation floating bridge device used in a bridge body maintenance process, which is characterized in that the device is formed by connecting a plurality of floating bridge body devices. A floating bridge body device comprises a floating bridge deck module and a floating bridge lifting module. The floating bridge deck module comprises a module bridge deck, a deformablefan blade, an angle adjusting motor and a connecting ring, wherein the angle adjusting motor is fixedly arranged on the module bridge deck, and the deformable fan blade is fixedly arranged on the angle adjusting motor; the floating bridge lifting module comprises a floating body fixing main body, a floating body telescopic auxiliary body and an airtight cloth, the floating body fixing main body is connected with the floating body telescopic auxiliary through the airtight clothe, and a sealed space is formed between the floating body fixing main body, the floating body telescopic auxiliary andthe airtight cloth, the space density of the whole device is changed through aeration and deflation, so that the lifting of the whole floating bridge lifting module is achieved. According to the invention, the assembly and deformation of the bridge body are achieved by utilizing a plurality of floating bridge body devices, and the movement of the floating bridge is achieved through a normal shipbody.

Owner:王剑

A cooling device for a portable computer

ActiveCN106325447BIncrease heightImprove ventilationDigital data processing detailsEngineeringHeat sink

The invention discloses a portable luggable computer heat dissipation device which comprises a left base and a right base. A group of damping springs is arranged on the left base and the right base respectively, the upper ends of the damping springs are matched with lifting sleeves, one end of each lifting sleeve is in screwed connection with a lifting bolt, the end of each lifting bolt is rotatably matched with a lifting push block arranged inside the corresponding lifting sleeve, the lifting push blocks are matched with lifting frames arranged inside the lifting sleeves, a group of cooling fans and carriages is arranged on the left base and the right base respectively, the carriage on the left base is connected with the carriage on the right base through a carriage telescoping rod, refrigeration frames penetrate into the carriages, and a group of semiconductor refrigerating sheets are arranged on the refrigeration frames. The portable luggable computer heat dissipation device is stable to place, has the characteristic of stretchable extension, is wide in applicability, can provide good bottom ventilation conditions for a luggable computer, further has a local refrigeration role and has pertinence in heat dissipation.

Owner:南通北外滩建设工程有限公司

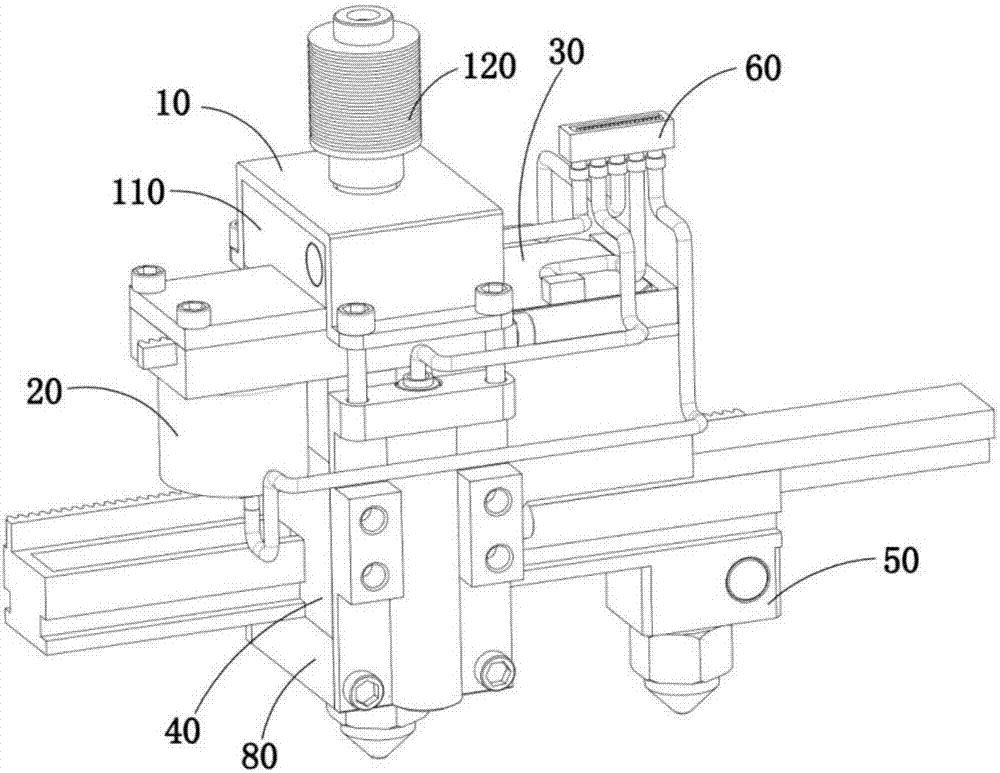

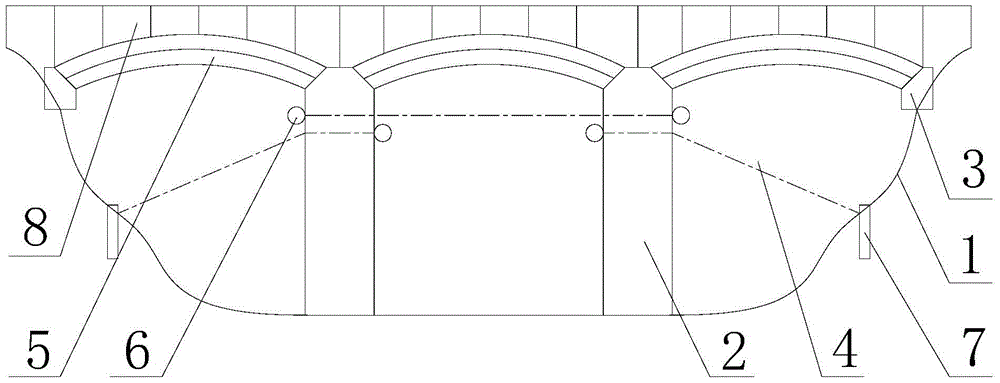

Span adjusting method for multi-head 3D printer

The invention discloses a span adjusting method for a multi-head 3D printer. The method comprises the steps: S1, when a molten raw material is accepted by a first communicating hole, making the molten raw material flow into a first extrusion head by the first communicating hole and a first melting runner, and carrying out extrusion molding by using the first extrusion head; S2, when the molten raw material is accepted by a second communicating hole, realizing the span adjustment between the first extrusion head and a second extrusion head in the process that a storage supporting body moves along a guide direction of a guide rail, making the molten raw material flow into the second extrusion head by the second communicating hole, a pushing trough and a second melting runner, and carrying out extrusion molding by using the second extrusion head; and S3, when the molten raw material is simultaneously accepted by the first communicating hole and the second communicating hole, making the molten raw material flow into the first extrusion head by the first communicating hole and the first melting runner, or making the molten raw material flow into the second extrusion head by the second communicating hole, the pushing trough and the second melting runner so as to realize the simultaneous work of the first extrusion head and the second extrusion head.

Owner:王亚军

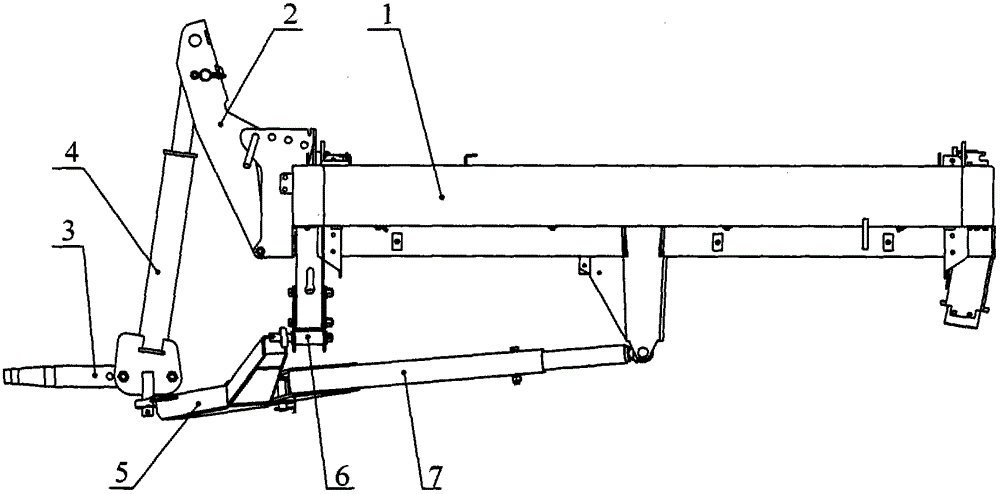

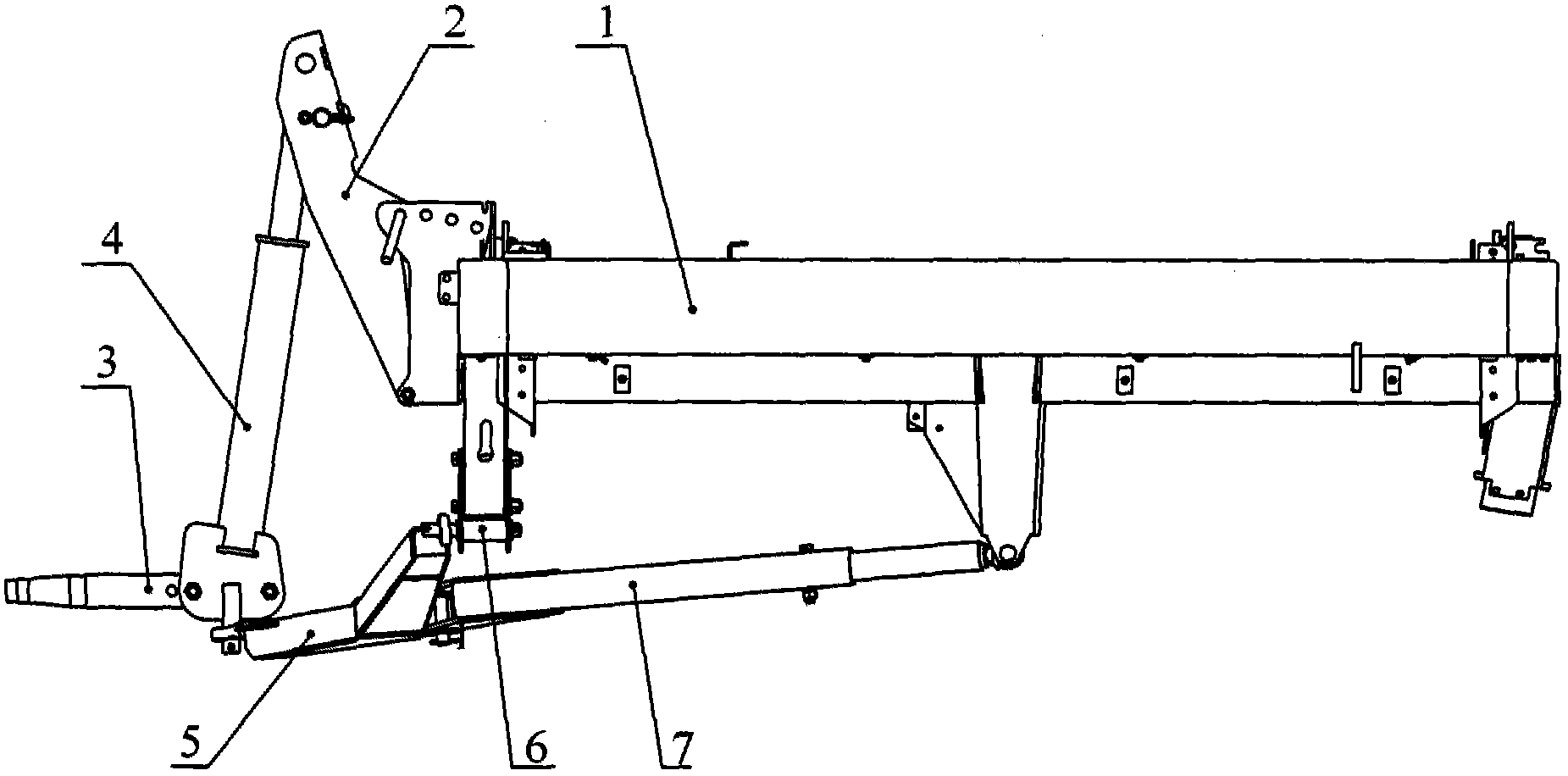

Potato Harvester Adjustable Frame

ActiveCN103797958BSolve the force problemFix workDigger harvestersAgricultural engineeringAnimal husbandry

The invention belongs to the field of agricultural and animal husbandry machinery, and particularly relates to an adjustable frame of a potato harvester. The adjustable frame of the potato harvester has functions that the span is adjustable, the frame is liftable, and operation requirements for different road conditions, work requirements and ground slopes are met. The adjustable frame of the potato harvester comprises a mounting frame, an adjusting rack, a right walking wheel axle, a seat equipped hoist cylinder, a front-rear adjusting rack welding piece, a front-rear adjuster and a span adjusting rack, wherein the adjusting rack is located on the right side of the adjustable frame ad are matched in two positions with the mounting frame for mounting and fixing; the seat equipped hoist cylinder is located on the right side of the adjusting rack, is hinged and fixed with the adjusting rack through a thick hinge pin and in rigid connection and fixation with the right walking wheel axle through a bolt B and a nut B, and a vertical shaft is welded on the seat equipped hoist cylinder and hinged and fixed with the front-rear adjusting rack welding piece; and the front-rear adjusting rack welding piece is located at the front lower part of the seat equipped hoist cylinder, and is connected and fixed in two positions with the mounting frame through the span adjusting rack and the front-rear adjuster.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI

Large-truss-height adjustable suspended splicing combined type frame steel arch frame and large-span arch ring integral pouring process

PendingCN114182652AImprove stabilityEven by forceBridge structural detailsBridge erection/assemblyStructural engineeringUltimate tensile strength

Owner:CHONGQING BIAOWANG MACHINERY EQUIP CO LTD

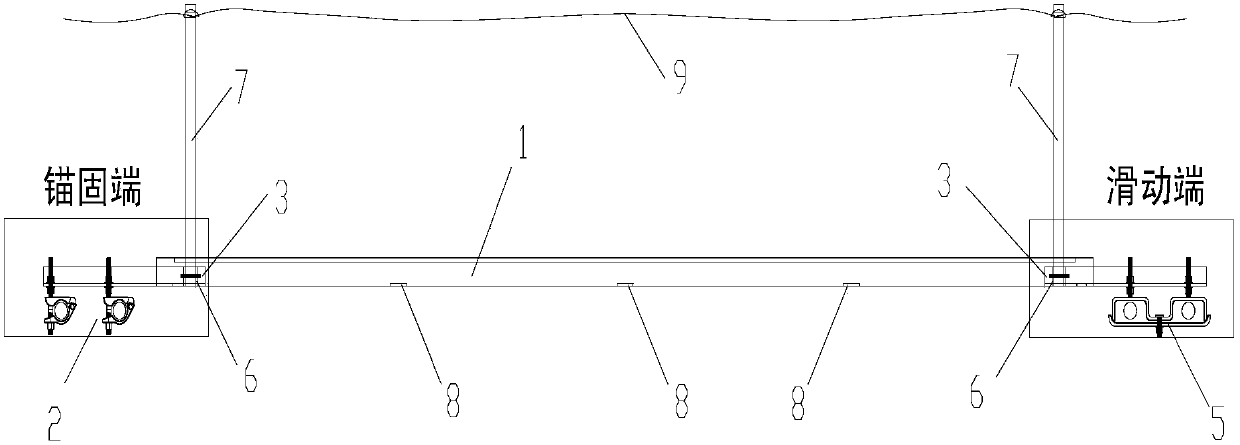

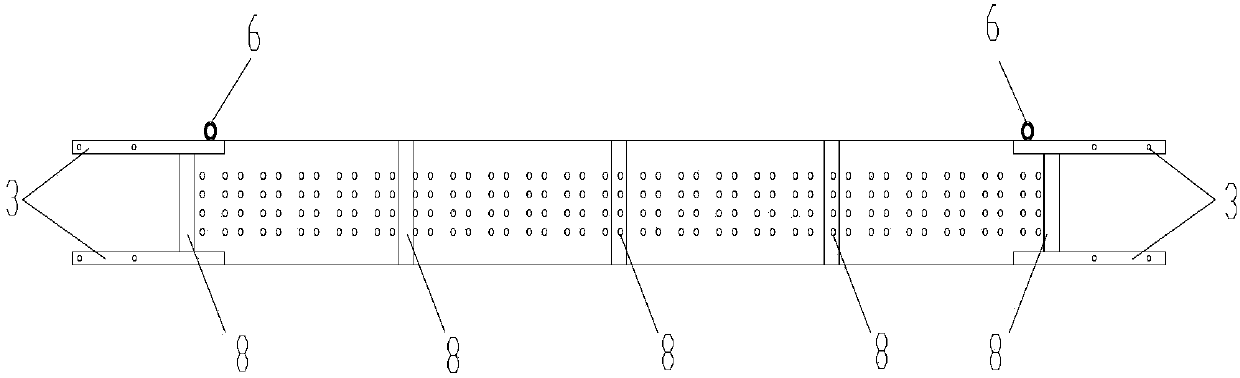

A self-anchoring adjustable pedal for erecting high-altitude catwalks

ActiveCN105971266BEasy to processEasy to useScaffold connectionsScaffold accessoriesSelf anchoringBuilding construction

The invention relates to construction protection equipment, in particular to a self-anchored adjustable pedal for erection of a high-altitude catwalk. Steel angles are arranged at two ends of each steel plate of the self-anchored adjustable pedal for erection of the high-altitude catwalk respectively, a plurality of vertical rods are arranged on the steel plate, and a lifeline is arranged between the vertical rods; self-anchored buckles are arranged on one steel angle at one end of each steel plate to form an anchoring end, and a combined sealable sliding chute is formed in the steel angle at the other end of each steel plate to form a sliding end; the anchoring ends and the sliding ends of a plurality of steel plates are mutually inserted and mutually spliced forwards and backwards to form the high-altitude catwalk. According to the self-anchored adjustable pedal for erection of the high-altitude catwalk, a few special requirements for erection of the catwalk on a structure cable are met, the span and the left-right height are adjusted, the structure cable can slide in the sealable sliding chute, the anchoring is reliable, and a flexible rubber cover for wrapping has an omnibearing protection function on the structure cable. The pedal is simple to process, firm to use, easy to mount and convenient to dismount.

Owner:NANJING NO 9 BUILDING INSTALLATION ENG

Hydraulic compound crane and its installation method

ActiveCN103723624BAdjustable spanBase supporting structuresBraking devices for hoisting equipmentsEngineering

Owner:TAIYUAN HEAVY IND +1

A wire cutting saw with variable arc length for processing hard and brittle materials

InactiveCN105108921BLow costAdjustable spanWorking accessoriesFine working devicesWire tensionWire cutting

The invention provides an arc-length-variable wire cutting saw for machining crisp and hard materials in the technical field of mechanical manufacturing and applied to extreme machining. The arc-length-variable wire cutting saw comprises a wire guide wheel drive mechanism, a wire cylinder and wire conveying mechanism, a wire tension adjusting and controlling mechanism, a driving and cutting mechanism, a stand column and beam and a workbench. The workbench is installed on a lower beam body of the stand column and beam. The wire cylinder and wire conveying mechanism is arranged on an upper beam body of the stand column and beam. The wire tension adjusting and controlling mechanism and the driving and cutting mechanism are arranged on a stand column of the stand column and beam. The wire guide wheel drive mechanism is fixed to the upper end of the stand column of the stand column and beam. A second lead screw is driven by a synchronous belt to rotate so as to drive a fist sliding base matched with the second lead screw to move up and down along a second guide rail. A first wire guide wheel and an adjusting wheel are fixed to the first sliding base through bearings. By means of the arc-length-variable wire cutting saw, the sawing wire can be much fine, and the saw seam width is lowered; the using rate is increased, and the span of cutting wheels of the wire saw is adjustable; and the wire cutting saw is small in saw shearing force, few in cuttings, low in noise, smooth and orderly in cut face, simple in structure and low in cost.

Owner:SHENYANG LIGONG UNIV

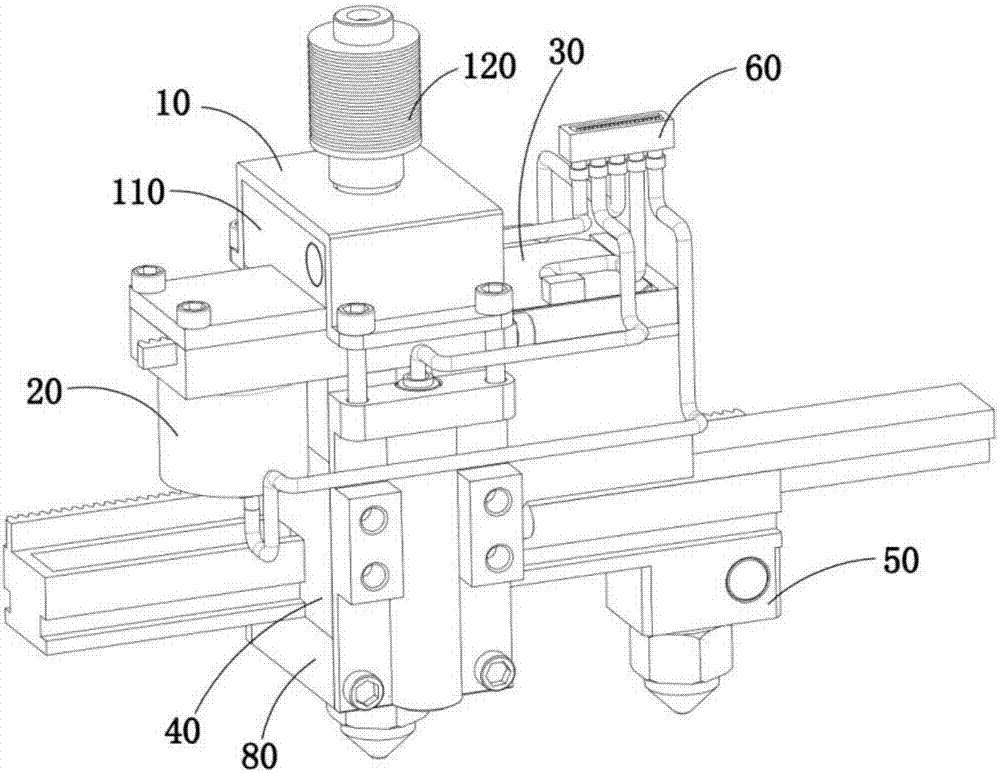

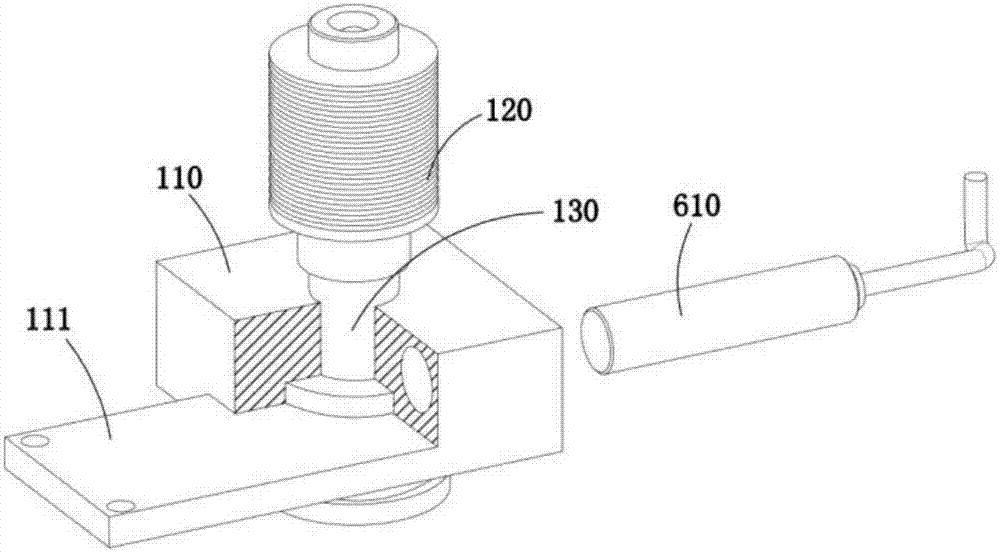

Multi-axis 3D printer with adjustable span

ActiveCN107322913AAdjustable spanManufacturing heating elementsAdditive manufacturing with liquidsMulti axis3d printer

The invention discloses a multi-axis 3D printer with the adjustable span. The multi-axis 3D printer with the adjustable span comprises a guiding support body and a guide rail which is fixedly connected with the guiding support body and extends horizontally. The guiding support body is provided with a first communicating hole and a second communicating hole. The first communicating hole and the second communicating hole can receive molten raw materials and guide the molten raw materials to flow. The guiding support body is further provided with a guide groove which is arranged in the guide direction of the guide rail and arranged on the surface of the guiding support body in a penetrating manner. The bottom plane of the guide rail is higher than the bottom plane of the guiding support body in the vertical direction. The bottom discharging end of the second communicating hole is arranged on the bottom plane of the guide rail in a penetrating manner. The bottom discharging end of the first communicating hole is arranged on the bottom plane of the guiding support body in a penetrating manner. A first extrusion mechanism is connected with the lower side of the guiding support body and can receive the molten raw materials flowing out from the first communicating hole. A second extrusion mechanism is further connected to the guiding support body in a sliding manner and can move in the guiding direction of the guide rail and receive the molten raw materials flowing out from the second communicating hole.

Owner:清研(洛阳)先进制造产业研究院

Adjustable frame of potato harvester

ActiveCN103797958ASolve the force problemFix workDigger harvestersAgricultural engineeringEngineering

The invention belongs to the field of agricultural and animal husbandry machinery, and particularly relates to an adjustable frame of a potato harvester. The adjustable frame of the potato harvester has functions that the span is adjustable, the frame is liftable, and operation requirements for different road conditions, work requirements and ground slopes are met. The adjustable frame of the potato harvester comprises a mounting frame, an adjusting rack, a right walking wheel axle, a seat equipped hoist cylinder, a front-rear adjusting rack welding piece, a front-rear adjuster and a span adjusting rack, wherein the adjusting rack is located on the right side of the adjustable frame ad are matched in two positions with the mounting frame for mounting and fixing; the seat equipped hoist cylinder is located on the right side of the adjusting rack, is hinged and fixed with the adjusting rack through a thick hinge pin and in rigid connection and fixation with the right walking wheel axle through a bolt B and a nut B, and a vertical shaft is welded on the seat equipped hoist cylinder and hinged and fixed with the front-rear adjusting rack welding piece; and the front-rear adjusting rack welding piece is located at the front lower part of the seat equipped hoist cylinder, and is connected and fixed in two positions with the mounting frame through the span adjusting rack and the front-rear adjuster.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI

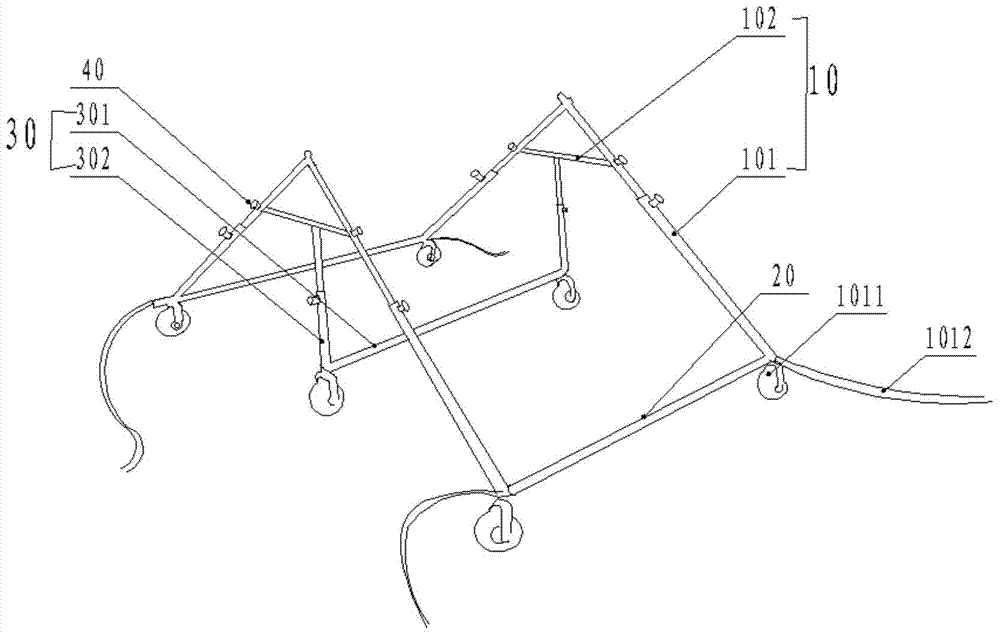

Transmission line release and withdrawal across the flying car

InactiveCN104934897BEnsure safetyRelieve pressureApparatus for overhead lines/cablesEngineeringOverhead line

The invention discloses a transmission line release and withdrawal crossing speeder, which belongs to the field of installation, maintenance and repair equipment for overhead lines or cables, and is used to solve the need to lower the crossing 10kv line during the transmission line release and withdrawal process. ground, resulting in low work efficiency. The present invention comprises a bearing frame and two left-right symmetrical brackets; the bracket includes two bracket legs, the tops of the bracket legs are connected together, the two bracket legs form a triangular structure with the ground, and pulleys and fixed ropes are installed at the bottom ends of the bracket legs; the bearing frame includes A rotating rod and a fixed rod, the rotating rod is located between two support rods, pulleys are fixed at both ends of the rotating rod, and the fixed rod is fixedly connected with the bracket. The invention has a wide range of applications, can significantly improve the work efficiency of setting and withdrawing wires, and can protect the crossed wires at the same time.

Owner:STATE GRID CORP OF CHINA +1

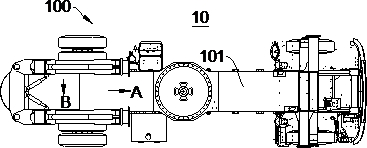

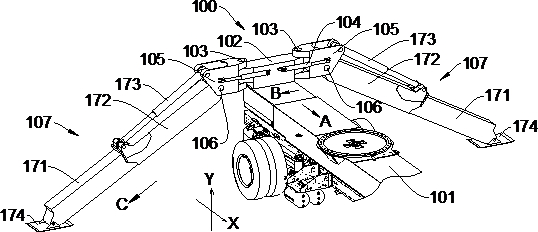

Supporting leg structure and automobile crane

InactiveCN111924726AAdjustable spanLow requirements for the work siteCranesVertical planeControl theory

The embodiment of the invention provides a supporting leg structure and an automobile crane, relates to the field of crane supporting legs, and aims to solve the problems that an existing supporting leg is small in span adjustable range and high in operation site requirement. The supporting leg structure comprises a chassis, a movable supporting leg and a hinged seat, the hinged seat is connectedto the chassis in a swinging manner, the movable supporting leg is connected to the hinged seat in a swinging manner; in the process that the hinged seat swings relative to the chassis, the movable supporting leg swings on the horizontal plane; and in the process that the movable supporting leg swings relative to the hinged seat, the movable supporting leg swings on the vertical plane. The automobile crane comprises the supporting leg structure. The movable supporting leg can swing on the horizontal plane and the vertical plane, so that the span of the movable supporting leg in the length direction and the width direction of the chassis is adjustable, the movable supporting leg can be suitable for various terrain operations, and the operation site requirement is low.

Owner:HUNAN SANY MEDIUM TONNAGE HOISTING MASCH CO LTD

Construction Method of Reinforced Concrete Multi-span Arch Bridge or Continuous Box Structure Bridge

ActiveCN104963292BSolve the problem of bearing the horizontal thrust of the longitudinal axisRealize a new construction processBridge erection/assemblyHorizontal forceReinforced concrete

The invention discloses a construction method of a reinforced concrete multi-span arch bridge or a continuous box structure bridge. The method is implemented according to the following steps: step 1) constructing the lower part structure of the arch bridge, wherein the lower part structure comprises a foundation, a middle pier and a bridge abutment; step 2) fixing flexible cables to piers of the arch bridge, fixing ground anchors through the flexible cables, and fixing the ground anchors to a ground to balance the horizontal force borne by the pier; step 3) erecting arch supports on each span of the bridge; step 4) constructing the upper part structure of the arch bridge on the arch supports; and step 5) removing the flexible cables and the arch supports. The construction method is simple in technology, reliable in quality, low in construction cost and rapider in construction speed, and the safety risk is lowered.

Owner:CHONGQING BIAOWANG INTEGRATED HOUSING TECH DEV CO LTD

A multi-axis 3D printer with adjustable span

ActiveCN107322913BAdjustable spanManufacturing heating elementsAdditive manufacturing with liquidsMulti axis3d printer

The invention discloses a multi-axis 3D printer with the adjustable span. The multi-axis 3D printer with the adjustable span comprises a guiding support body and a guide rail which is fixedly connected with the guiding support body and extends horizontally. The guiding support body is provided with a first communicating hole and a second communicating hole. The first communicating hole and the second communicating hole can receive molten raw materials and guide the molten raw materials to flow. The guiding support body is further provided with a guide groove which is arranged in the guide direction of the guide rail and arranged on the surface of the guiding support body in a penetrating manner. The bottom plane of the guide rail is higher than the bottom plane of the guiding support body in the vertical direction. The bottom discharging end of the second communicating hole is arranged on the bottom plane of the guide rail in a penetrating manner. The bottom discharging end of the first communicating hole is arranged on the bottom plane of the guiding support body in a penetrating manner. A first extrusion mechanism is connected with the lower side of the guiding support body and can receive the molten raw materials flowing out from the first communicating hole. A second extrusion mechanism is further connected to the guiding support body in a sliding manner and can move in the guiding direction of the guide rail and receive the molten raw materials flowing out from the second communicating hole.

Owner:清研(洛阳)先进制造产业研究院

Multifunctional assembly and disassembly equipment for parts of dynamical system of new energy vehicles

InactiveCN103111992BAccurate and easy disassemblyIngenious designWork benchesVehicle frameNew energy

The invention relates to a multifunctional assembly and disassembly equipment for parts of a dynamical system of new energy vehicles. Bottom wheels can be rotatably installed beneath a chassis and support the chassis. An auxiliary vehicle frame is supported on the chassis and is arranged in a left and right moving mode relative to the chassis. A top plate is supported on the auxiliary vehicle frame and is arranged in an up and down moving mode relative to the auxiliary vehicle frame. A support platform is rotatably arranged on the top plate by rotating around the rear end. A motor support installation platform and a replaceable support installation platform are arranged adjacent to each other and are both arranged on the support platform in a front and back moving mode. A motor support is arranged on the motor support installation platform, a replaceable support is arranged on the replaceable support installation platform, and the replaceable support is an engine support or a gearbox support. The multifunctional assembly and disassembly equipment for parts of the dynamical system of new energy vehicles is ingenious in design, enables assembly and disassembly of parts of the dynamical system of new energy vehicles to be accurate, simple and convenient, greatly simplifies an installation process, reduces investment on manpower and material resources, decreases the number of times of adjustment, greatly improves work efficiency and is suitable for large-scale popularization and application.

Owner:JIANGXI B ENERGY SHANGRAO COACH

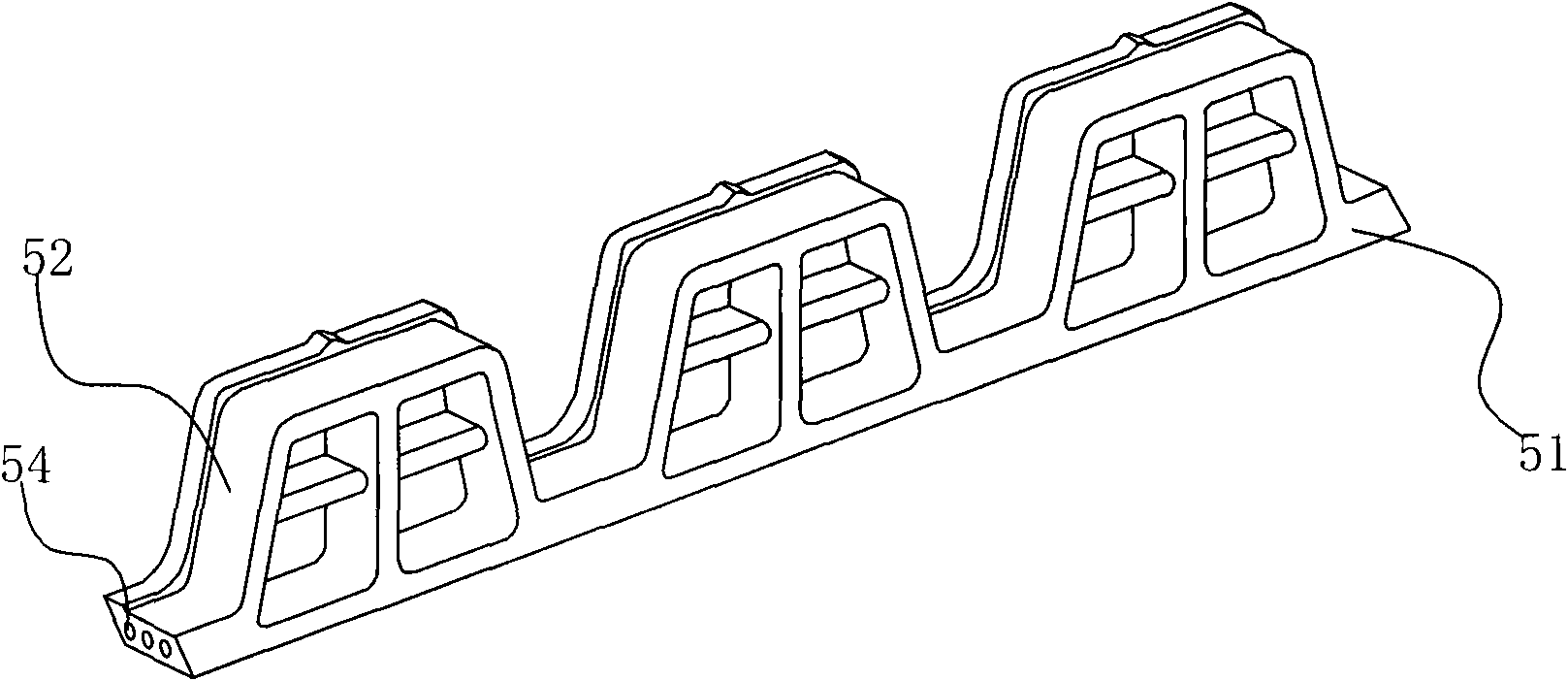

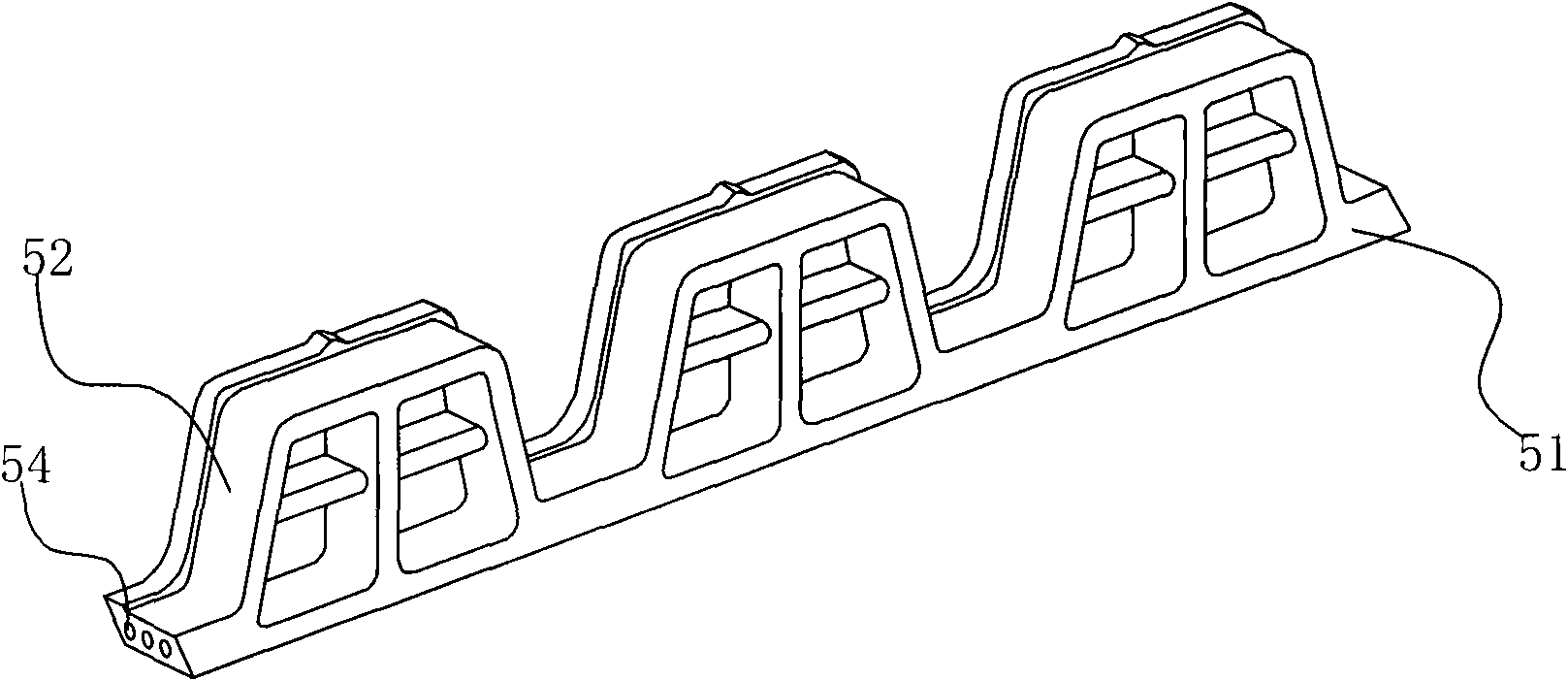

Large-span light subway evacuation platform plate and manufacturing process thereof

PendingCN114658477AImprove carrying capacityImprove deformation resistanceCeramic shaping mandrelsCeramic shaping coresCrack resistancePre stress

The invention discloses a large-span light subway evacuation platform plate and a manufacturing process thereof, and belongs to the technical field of assembly. In order to solve the problems that the construction speed is affected due to the fact that an existing subway evacuation platform plate is large in weight, difficult to assemble and small in span, and fire resistance, cracking resistance, corrosion resistance and the like cannot be considered at the same time, a novel light-weight high-strength concrete material is developed, and the platform plate takes the novel material as a base body, takes a hollow ribbed structure as a plate type and takes basalt fiber woven ribs as prestressed ribs; rib feet are arranged, a steel pipe system is embedded, and prestress is applied to the lower portion of the plate, so that the hollow plate, the steel pipe system and prestressed tendons form a balance system, and the bottom face of the main plate is pressed but not pulled. The limitation that prestress cannot be applied in an existing platform plate due to plate thickness limitation is broken through. The advantages of materials, prestress and a combined structure are fully exerted, and the manufactured platform plate has the characteristics of light weight, large span, fire resistance, cracking resistance, erosion resistance and the like, and has remarkable economic benefits and wide engineering applicability.

Owner:HARBIN INST OF TECH

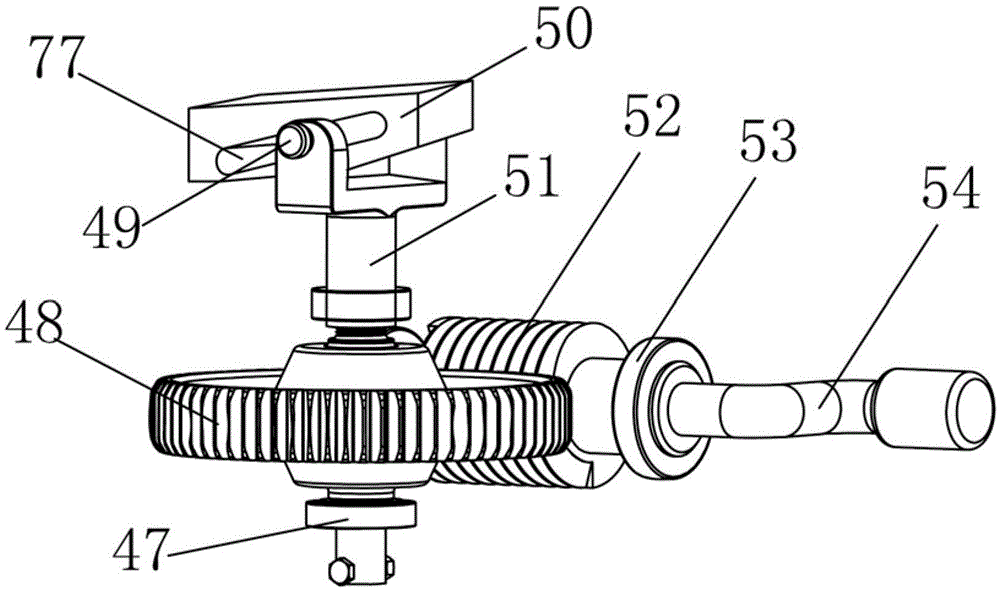

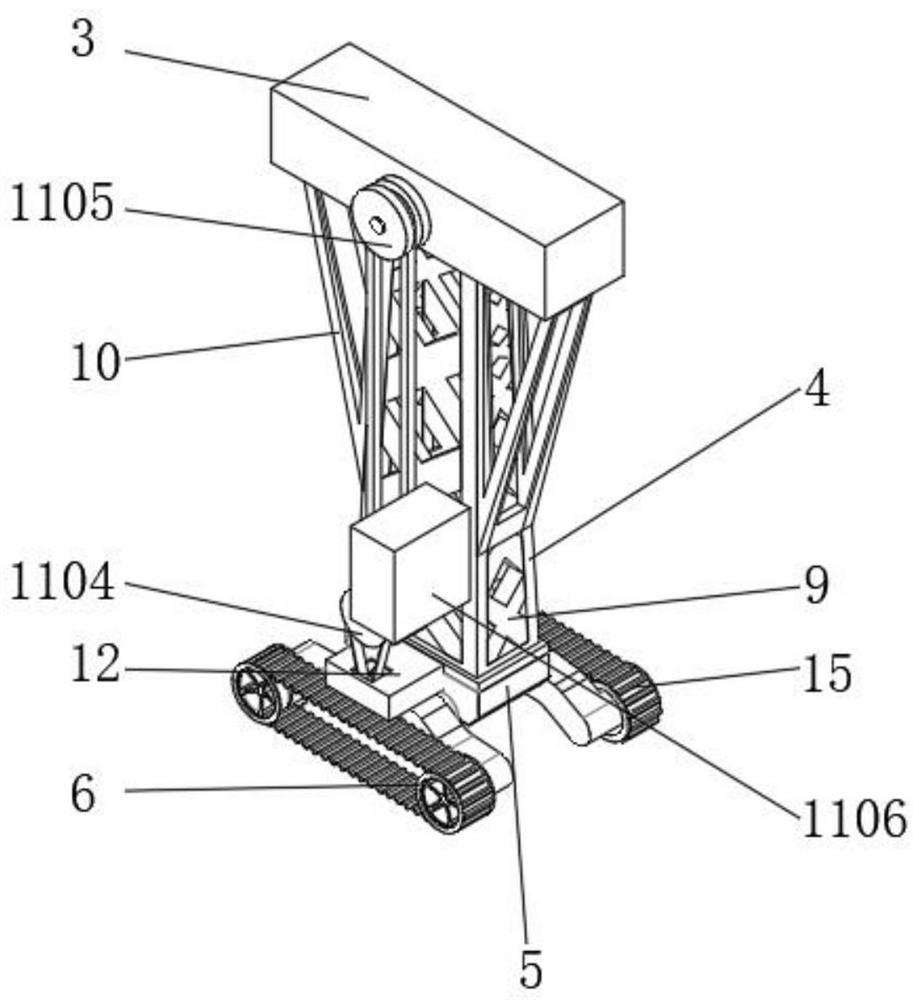

Span-adjustable beam lifter

PendingCN112194012AAdjustable spanEasy to moveBase supporting structuresBraking devices for hoisting equipmentsBraced frameGear wheel

The invention discloses a span-adjustable beam lifter which comprises a cross beam. An adjusting structure is arranged on one side face of the cross beam, a fixing block is fixedly connected to the lower surface of the adjusting structure, a supporting frame is fixedly connected to the lower surface of the fixing block, and a box body is fixedly connected to the lower surface of the supporting frame. A transmission structure is arranged in the box body, and the adjusting structure comprises a sliding clamping ring, a rack, a limiting box, a gear, a screw rod and a first-stage servo motor. According to the span-adjustable beam lifter, through cooperation of rolling wheels and the transmission structure, the span-adjustable beam lifter has the effects of being capable of moving transverselyand vertically, so that the effect that movement is convenient is achieved; and through cooperative arrangement of the adjusting structure and the cross beam, in the using process, the supporting frame can be indirectly driven to move through the first-stage servo motor, then the effect of improving the applicability is achieved, and the purpose of adjusting the span is achieved.

Owner:华建重工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com