Tubular product rope saw ultrasonic cutting equipment

A technology of ultrasonic cutting and wire sawing, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., and can solve the problems of low precision, large fluctuation, and unfavorable wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

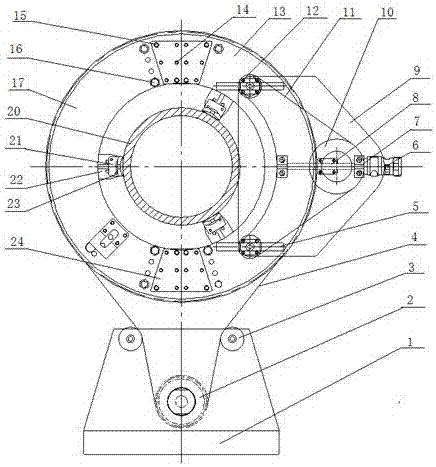

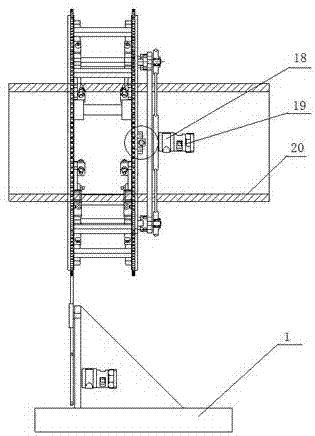

[0013] Referring to the accompanying drawings, an ultrasonic cutting equipment for a pipe wire saw is composed of a sprocket disc rotation mechanism, a sliding table drive feed mechanism, and a wire saw (wire saw) movement mechanism, including a base 1, a turntable drive motor, a sprocket 2, an expansion Tightening wheel 3, conveyor chain 4, sliding table guide rail pair 5, sliding table driving motor 6, coupling 7, sliding table screw nut pair 8, sliding table 9, wire saw driving wheel 10, wire saw 11, cutting guide Wheel 12, right semicircular chain wheel disc 13, positioning pin 14, connecting bolt 15, positioning connecting rod 16, left semicircular chain disc 17, torsional vibration transducer 18, wire saw drive motor 19, workpiece 20, mobile positioning pressure head 21. Move the positioning pressure head seat 22, the adjustment bolt 23, and the sprocket plate 24. The right semicircular sprocket plate 13 and the left semicircular sprocket plate 17 are installed on the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com