Hydraulic compound crane and its installation method

An installation method and a crane technology, which are applied in hoisting devices, traveling mechanisms, transportation and packaging, etc., can solve the problems of high risk factor, large floor area, and high cost of hardening the foundation of the wind rope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

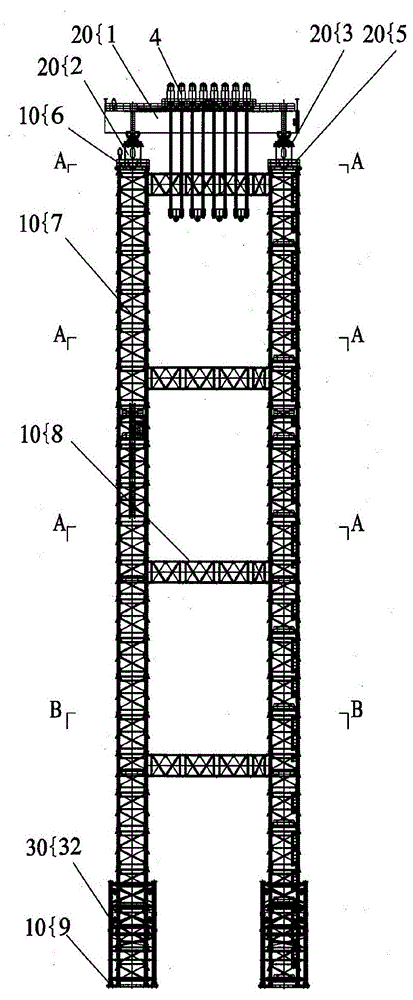

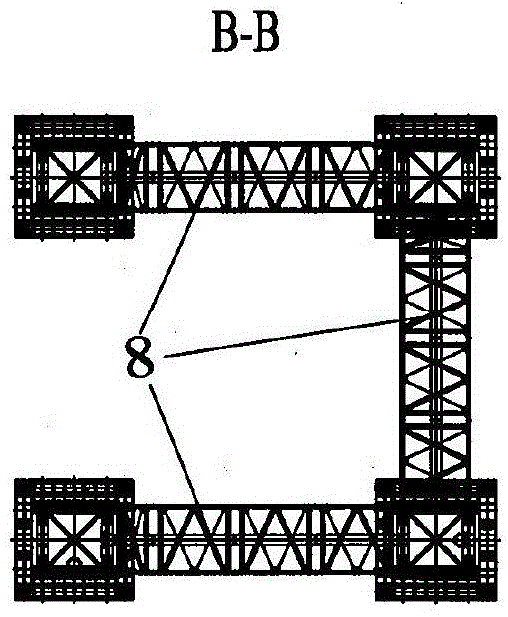

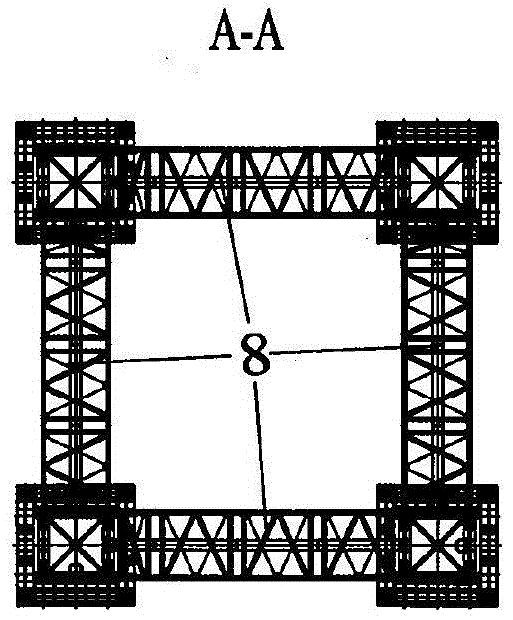

[0030] figure 1 Shown is a front view of a large hydraulic compound crane according to an embodiment of the present invention. Figure 1A for along figure 1 Schematic cross-sectional view of line B-B in middle. Figure 1B for along figure 1 A schematic cross-sectional view of the A-A line. figure 2 Shown is a left view of a large hydraulic compound crane according to an embodiment of the present invention. Such as figure 1 , Figure 1A and Figure 1B and figure 2 As shown, the present invention provides a large hydraulic compound crane, which includes a mast unit 10 , a sliding unit 20 and a dismounting unit 30 . The door frame unit 10 has four groups of door legs parallel to each other and arranged in a square shape. The dismounting unit 30 is arranged on the lower part of each group of door legs and is used to disassemble the door frame unit 10. The sliding unit 20 is arranged on the door frame unit 10. above.

[0031] Such as figure 1 , Figure 1A and Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com